Metal clad plate refers to a plate covered with another metal on one layer of metal, which has achieved the effect of saving resources and reducing costs without reducing the use effect (anti-corrosion performance, mechanical strength, etc.). The composite methods usually include explosive composite, explosive rolling composite, rolling composite and so on. It is mainly used in anti-corrosion, pressure vessel manufacturing, power construction, petrochemical, pharmaceutical, light industry, automobile and other industries.

Metal composite plate is a composite material formed by metallurgical combination of metals with different properties on the interface by using various composite technologies. Through appropriate material selection and reasonable structural design, metal composite plates can greatly improve the thermal expansion, strength, toughness, wear resistance, corrosion resistance, electrical properties, magnetic properties and other properties of single metal materials. Therefore, they are widely used in petroleum, chemical industry, shipbuilding, metallurgy, electric power, water conservancy, transportation, environmental protection, food, pharmaceutical and other industrial fields. In addition to the structural and functional characteristics, metal composite plates can also save the use of precious metals and significantly reduce the cost of various equipment materials.

Product advantages and features:

1. It can give full play to the respective advantages of component materials, realize the optimal allocation of component material resources and save precious metal materials;

2. The cost is greatly saved, and the various mechanical properties of the substrate are hardly changed;

3. Save resources and reduce costs;

4. Increased production flexibility.

Type of metal clad plate:

According to the material of metal clad plate, it can be divided into the following two categories:

① Titanium zinc composite plate

② Copper aluminum composite plate

A、Titanium zinc composite plate

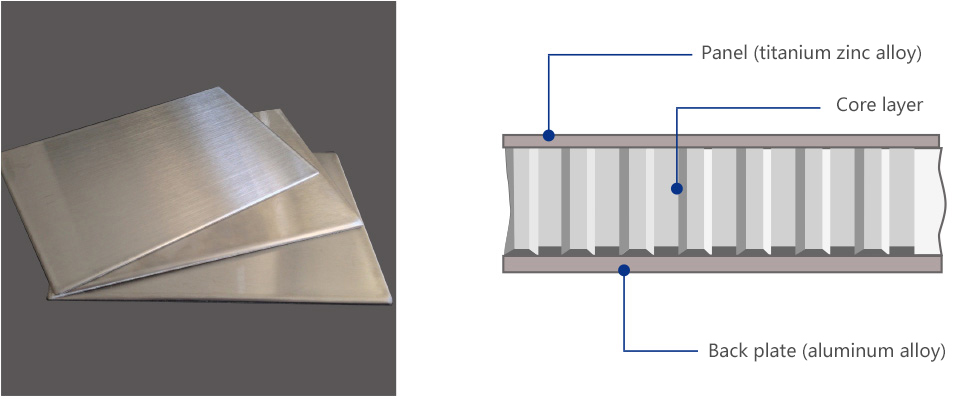

Zinc composite plate is a new type of high-grade aluminum plastic plate building material made of titanium zinc alloy plate as the panel, 3003h26 (H24) aluminum plate as the back plate and high-pressure low-density polyethylene (LDPE) as the core material. It integrates the characteristics of titanium zinc plate (metal texture, surface self-healing function, long service life, good plasticity, etc.) with the advantages of flat composite plate and high bending resistance, It is a model of the combination of classical art and modern technology.

Hanbert titanium zinc composite plate is made by continuously bonding two thin aluminum skins on both sides of extruded LDPE or mineral flame retardant thermoplastic core material. The aluminum surface has been pretreated before lamination and rolled on various painted surfaces.

Raw material:

Surface layer: titanium zinc

Core layer: LDPE, FR, HFR, A2

Backing: Aluminum

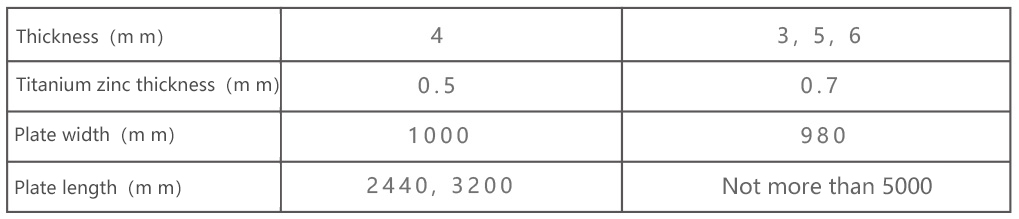

Standard specification:

Product advantages and features:

1. Excellent flatness and rigidity;

2. Large size panel;

3. Strong structural stability;

4. Processed into various complex shapes;

5. Zinc has a long service life.

B、Copper aluminum composite plate

Copper aluminum composite plate is a new material that can not be separated by welding copper plate and aluminum plate together through cold rolling, hot rolling, explosive composite method, explosive rolling method and so on.

Hanbert copper composite plate adopts copper plastic aluminum composite, with flat surface and easy processing and forming, which saves a lot of precious copper materials than single copper plate. The surface of natural copper is bright red. Affected by natural oxidation, it will change from bright red → dark red → ancient copper → green copper, which fully shows the life characteristics of copper decorative color changing with time. If the surface is coated with fingerprint resistant transparent paint, the color change process can be delayed. The copper surface can also be artificially oxidized and colored to bronze, bronze or green copper.

Raw material:

Surface layer: red copper (brass, copper green, etc.)

Core layer: LDPE, FR, HFR, A2

Back layer: red copper (brass, copper green, etc.) or aluminum

Surface: natural primary color, varnish, bronze, copper green

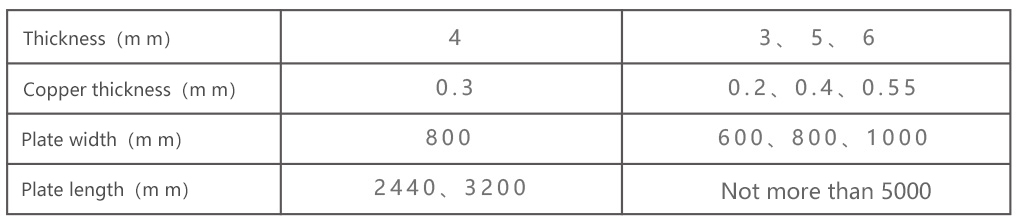

Standard specification:

Product advantages and features:

1. Excellent flatness and rigidity;

2. Large size panel;

3. Strong structural stability;

5. It can be processed into complex shapes;

5. Noble decoration of copper;

6. Low cost and light proportion: compared with pure copper, composite products of the same volume can save customers at least 60% of the cost;

7. Excellent processing performance: its bending performance is better than that of the same conductor of the same specification, and it is easy to process. Due to the high interface bonding strength, copper and aluminum are not layered during shearing, punching and bending;

8. Excellent thermal conductivity: copper aluminum composite plate and strip are cold rolled into plates and strips of different thickness. Because it is oxygen free metallurgical composite, it has no heat transfer contact thermal resistance, and has good heat transfer performance of copper and aluminum metals.