01.

What is hyperbolic aluminum veneer?

Double curvature aluminum veneer is a new type of building material. Its appearance is mainly designed in the shape of hyperbola, which has a very high decorative effect and beauty.

During the production process of hyperbolic aluminum veneer, high-strength aluminum alloy materials are used to effectively enhance its quality and durability. Due to the excellent plasticity of metal aluminum plates, they can be designed and processed according to various curvatures, meeting the personalized construction requirements of the construction party.

At the same time, the surface of the hyperbolic aluminum veneer has undergone special treatment, providing multiple safety measures such as fire prevention, waterproofing, and anti-corrosion. In practical applications, hyperbolic aluminum veneer can be widely used in the decoration and structural aspects of exterior walls, ceilings, partitions, etc. of buildings, and is widely concerned and favored due to its high quality, environmental protection, durability, and other characteristics.

The common aluminum veneer is generally flat, while the molded aluminum veneer is divided into many kinds of single curved surface and hyperboloid.

The difference between single surface and hyperboloid is that single surface veneer is light and rigid. Can create a multi-level space, and can design multiple colors to be applied to more buildings The hyperboloid veneer is waterproof with internal structure and sealed, thus ensuring its excellent waterproof performance to a greater extent. Secondly, the production of hyperboloid veneers is difficult and requires high accuracy of machines and skilled workers.

02.

Specification of hyperbolic aluminum veneer

Hyperbolic aluminum veneer refers to a shaped panel that is different from conventional aluminum veneer. It is formed by repeatedly machine bending, stretching, and manual polishing of conventional aluminum veneer according to design needs to form aluminum veneer with different shapes and shapes.

The production process of hyperbolic aluminum veneer is complex, with high technical requirements and higher cost compared to conventional ones. However, with various shapes and rich and beautiful colors, it meets the needs of architectural design and creates an architectural design style that fully demonstrates the unique design style and architectural philosophy of designers. Usually, the thickness of hyperbolic aluminum veneer comes in specifications such as 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm.4.0mm, etc.

03.

Characteristics of hyperbolic aluminum veneer

1、High strength

High strength, and due to the welding process used at the opening, the rigidity of the aluminum plate is greatly improved, ensuring the wind resistance, shock resistance, rainwater leakage resistance, air penetration resistance, lightning protection, and impact resistance of the curtain wall. The aluminum veneer can be processed into flat plates of different specifications, double curved panels and profiled plates. After forming, after surface treatment, it can be used for fluorocarbon spraying, acrylic acid spraying and powder spraying. The color can be arbitrarily selected and is often used for indoor and outdoor decoration.

2、Rich colors and good decorative effects

According to user needs, it can be processed into various geometric shapes and sprayed with various colors. Moreover, spraying technology and equipment are used to ensure uniform spraying and strong adhesion.

3、High Cleanliness

Its surface dust cannot adhere at all, so it does not need to be cleaned. In addition, it uses ion and water contact surface tension technology, so it has good self-cleaning performance.

4、High weather resistance

Effectively resist acid rain, air pollution, and UV light erosion, ensuring 10 years of non peeling and non powdering.

5、Light weight and good rigidity

6、Easy and fast installation

Aluminum veneer can be processed and formed according to customer drawings in the factory, and installed on-site.

04.

Construction technology of hyperbolic aluminum veneer

a、Sheet metal processing

Mainly aimed at the processing of the appearance, size, and other "general directions" of hyperbolic aluminum veneer, the processing process mainly focuses on the processing of the appearance, size, and other aspects of hyperbolic aluminum veneer.

b、Appearance

Use cutting, edge folding, arc bending, welding, polishing and other processes to process aluminum veneer into the required shape and dimensions for construction.

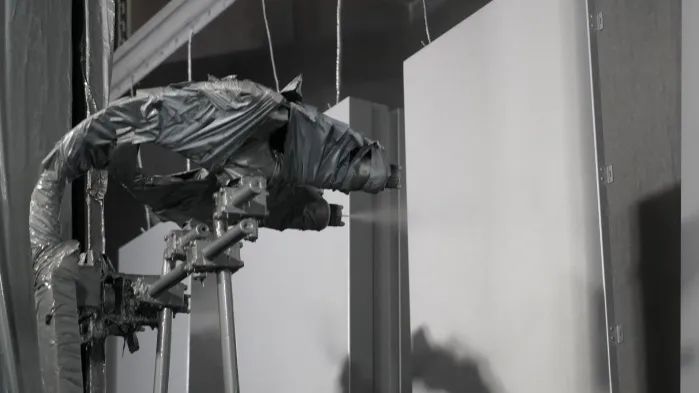

c、Spraying process

Spraying is the process of spraying paint on processed aluminum plates, which can be divided into manual spraying and machine spraying. Generally, machine spraying is only suitable for regular plates, but it is seldom used. Manual spraying can be of any size and color. Before spraying, hyperboloid aluminum veneer needs to be cleaned to achieve the best effect.

05.

Application cases of hyperbolic aluminum veneer

1、Jinchang Yanbo Star Heron

Location: Shaoxing/Design: Zero One City Architecture Firm

In the era of real stone paint on the facade, Jinchang was the first to introduce aluminum panel facades to Shaoxing. The Waixian Feige, custom-made from hyperbolic aluminum panels, is like the wings of an egret transformed, showcasing the soft power of the Yanbo Star Heron.

From aluminum ingots, flat plates, cutting to later welding, reinforcement assembly, spraying, and packaging of finished products, only through 16 processes operated by professional technical workers can a hyperbolic aluminum plate be formed. Only the "spraying" process needs to go through 16 high standard procedures. The special fluorocarbon spraying technology, with excellent anti fading and anti frost properties, achieves the eternal renewal of the exterior facade of the top luxury.

2、Jinchang · Smoke Wave Flying Heron

Location: Shaoxing/Design: Ji Yi City Architecture Firm

Innovatively picking out the eaves and directly pulling the Jinchang curve from 2D to 3D, showcasing strong artistic tension. Adding a sense of depth and strength to the lightweight architecture, while the villa villa boldly adopts champagne gold tones, the high-end texture is not self evident.

The large area double layer hollow LOW-E glass customized by the manufacturer, with a single area far exceeding market standards, means multiple challenges for glass size enjoyment, transportation and installation, as well as multiple cost investments. The eaves aluminum panel has undergone multiple complex details such as material comparison, form matching, factory customization, and process engineering.

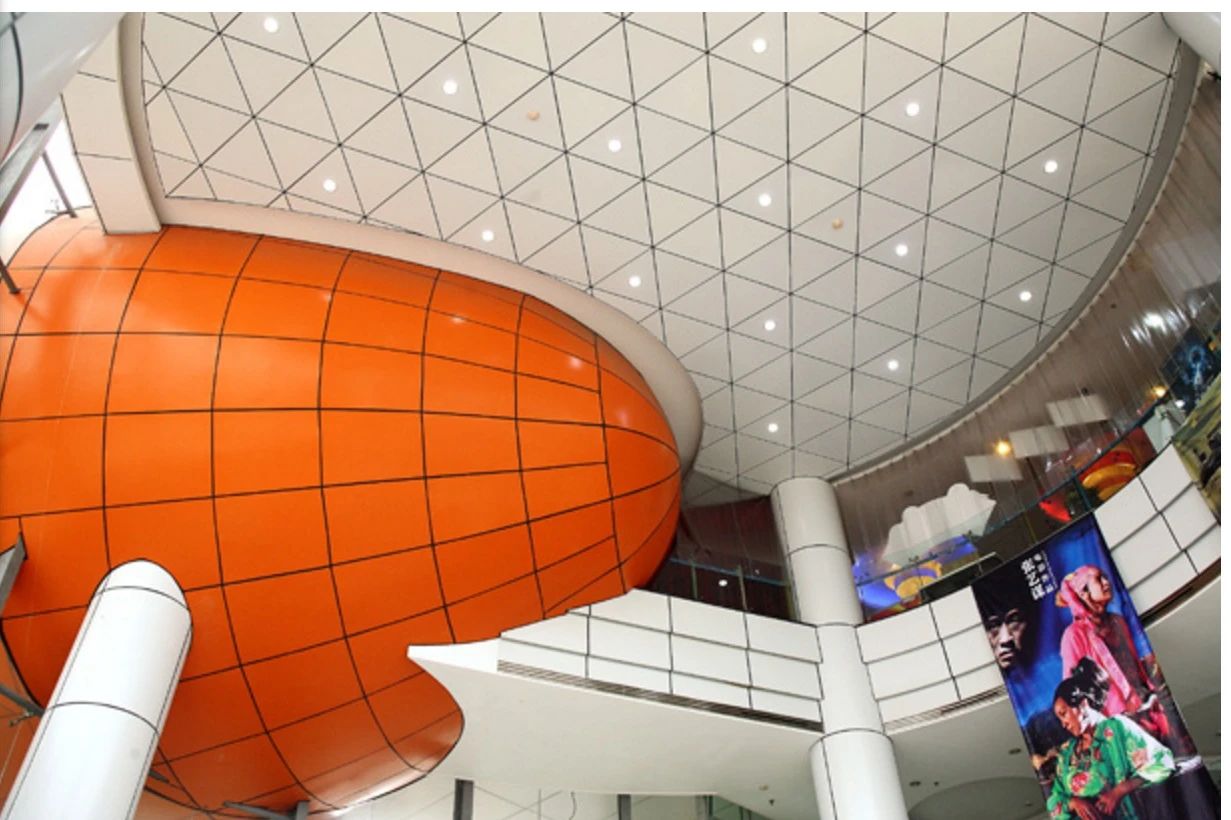

3、Xuhui Donut Kindergarten

Location: Hefei/Design: Tianhua Architectural Creation Studio

Through the flow and twisting of white aluminum plates on the surface, the building facade appears smooth and rhythmic in appearance. The aluminum plate with wood grain transfer printing serves as a backdrop, further adding a warm and delicate atmosphere to the building. The hyperbolic aluminum plate has been fully optimized during the deepening process, achieving a balance between modular processing and architectural expression.

4、Nanjing Jindi Weixin · Yuhua Innovation Center

Location: Nanjing/Design: Chengzhi Design

The design adopts a relatively simple approach to overall planning and interpretation of the facade. The building facade, composed of champagne golden aluminum panels and glass curtain walls, has a strong sense of transparency, simplicity, and atmosphere. The aluminum panel transitions and changes enrich the human visual experience, and the design sense expressed through careful deduction makes simplicity and refinement not contradictory.

5、BEEAH Group New Headquarters

Location: UAE/Design: Zaha Hadid Architects

Article transferred from design materials