01.Material Overview

Metal aluminum plate refers to a type of metal material that is rolled and processed from aluminum ingots and is commonly used in the construction industry.

02. Material classification

From the perspective of classification logic, aluminum panels used in the construction and decoration industry are mainly divided into two categories: "aluminum veneer" and "composite board".

A.aluminum veneer

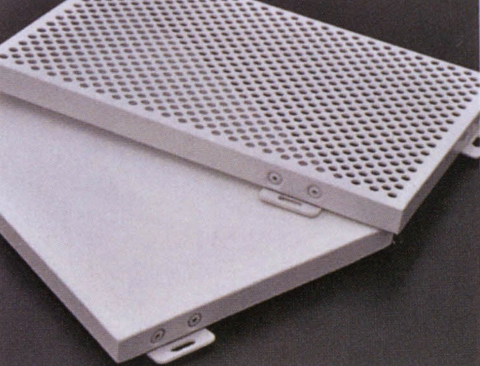

▲Aluminum veneer

Aluminum veneer is a new type of building decoration material that is based on aluminum alloy sheets, treated with chrome and other processes, and then formed through CNC bending and other technologies. It is processed using technologies such as fluorocarbon or powder spraying. Due to its smooth surface, good weather resistance, and easy cleaning, it is widely used as a wall and roof material in indoor and outdoor environments of buildings.

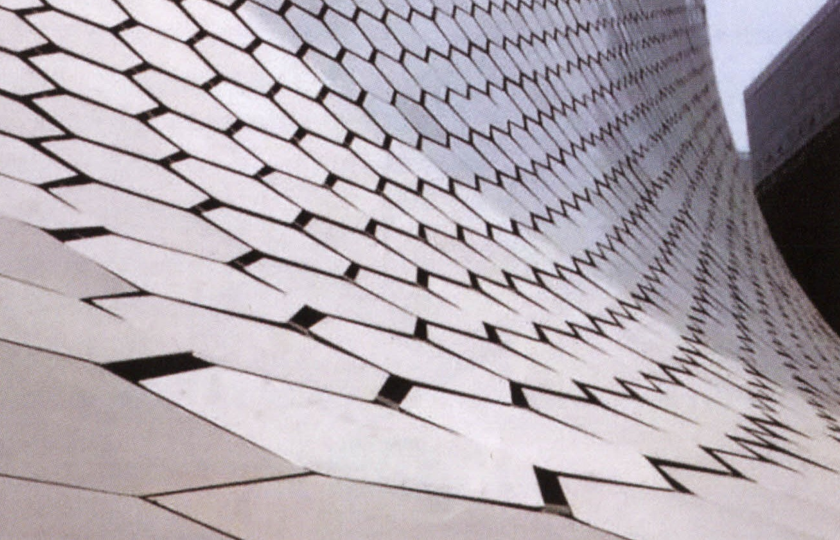

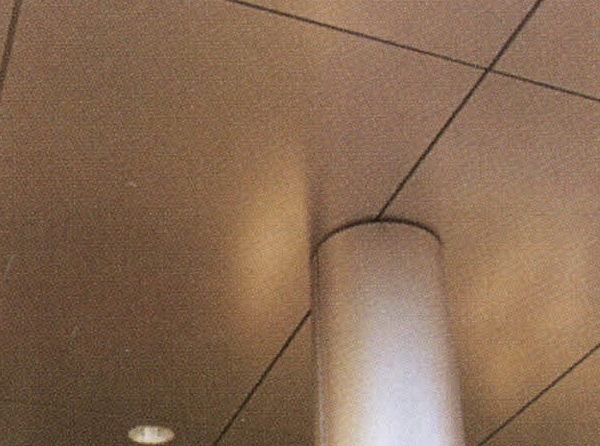

▲The Application of Aluminum Veneer in Indoor Space

▲The application of aluminum veneer in building curtain walls

03. Popular Science: Introduction to Various Aluminum Veneers

1、Punched aluminum veneer

Punched aluminum veneer is a decorative board that uses advanced CNC punching equipment to drill various shapes of holes on the surface of aluminum veneer according to design drawings. Various fillers can be added according to special needs.

2、Carved aluminum veneer

Through different patterns and carved aluminum veneers, various artistic design patterns are carved on the surface of the aluminum veneers using a carving machine. The combination of different environments breaks through traditional design concepts, making the aluminum carved lines more lively and elegant.

2、Wood grain aluminum veneer

Wood grain aluminum veneer is the effect of using powder to treat the surface of the aluminum veneer into wood grain. As a brand new green and environmentally friendly product, wood grain aluminum veneer has high-end and gorgeous patterns, authentic color and texture, firm patterns, wear resistance, formaldehyde free, non-toxic, and no harmful gas release.

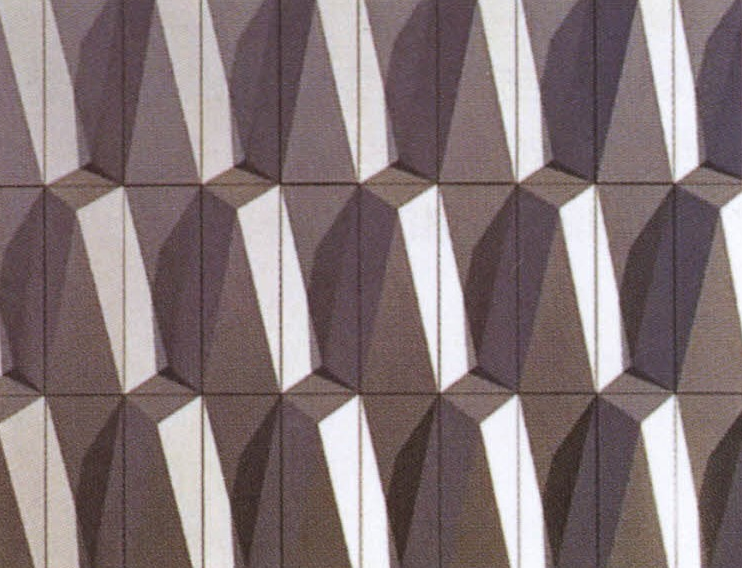

3、Imitation stone aluminum veneer

Imitation stone aluminum veneer is a new decorative material that is based on aluminum veneer and processed through a special spraying process to give aluminum veneer a strong three-dimensional sense of stone.

4、fluorocarbon aluminum veneer

Fluorocarbon aluminum veneer, also known as flat aluminum veneer. The surface coating of nitrogen carbon aluminum veneer is divided into fluorocarbon spraying, powder spraying, polyurethane coating, and fluorocarbon pre roller coating according to customer needs. Fluorocarbon sprayed surface coatings can be divided into two coating and one baking, three coating and one baking, and three coating and two baking according to the processing technology. Powder sprayed surface coatings are one coating and one baking. The color of fluorocarbon aluminum veneer can be freely chosen by customers

5、Special shaped aluminum veneer

Shaped aluminum veneer refers to the aluminum veneer that can be made into curved roller aluminum veneer, conical aluminum veneer, curved aluminum veneer, and other shapes according to different designs. Styled aluminum veneer is a highly decorative and aesthetically pleasing aluminum product.

B.Composite board

▲Aluminum composite panel

Aluminum composite plate is a general term that mainly refers to the use of various complex processing methods to composite chemically treated coated aluminum plates (aluminum veneers) as surface materials onto suitable base materials, ultimately forming aluminum composite plates. According to the different composite base materials, aluminum composite plates have different material characteristics.

For example, the common aluminum plastic board is a composite board of plastic and aluminum veneer, which not only retains the characteristics of plastic materials, but also overcomes the shortcomings of plastic materials through metal materials.

▲The application of aluminum plastic panels in building curtain walls

▲The application of aluminum plastic panels in indoor environments

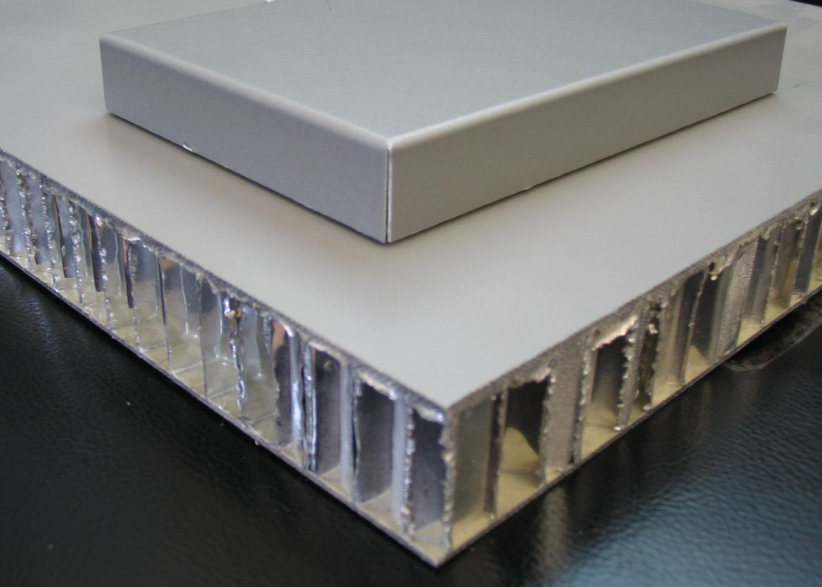

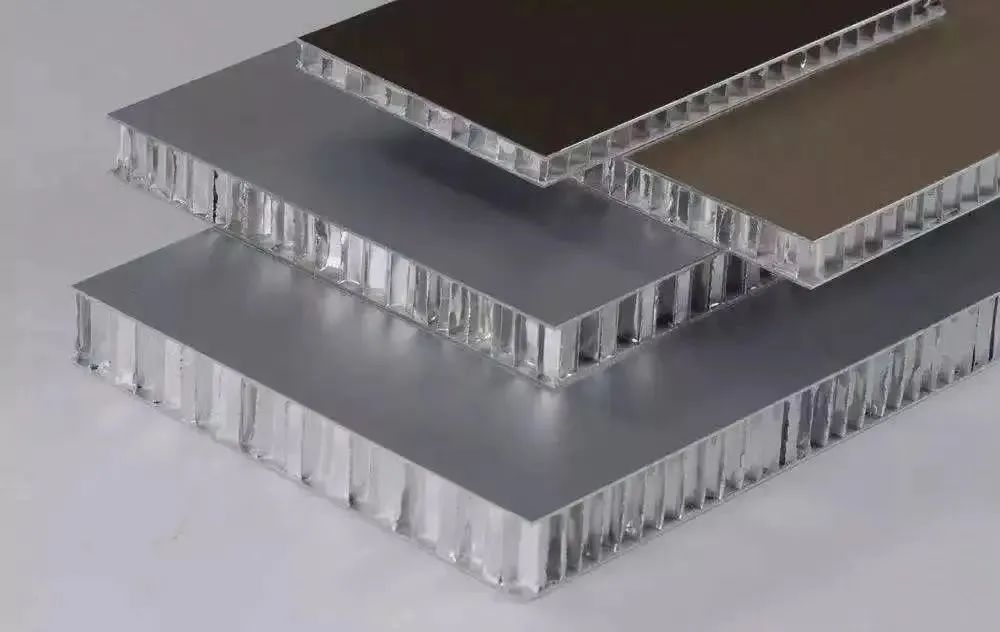

Another common type of aluminum composite plate is honeycomb aluminum plate: it is a composite material composed of honeycomb metal and aluminum veneer. In addition to retaining the decorative performance characteristics of aluminum veneers, the honeycomb metal structure base layer greatly compensates for the disadvantage of aluminum veneers being prone to bending. In more and more large-scale space applications, this material is used to ensure the flatness of the decorative material.

▲Metal honeycomb panel

04. Material characteristics

Advantages of aluminum veneer:

a、Light weight and high strength

3.0mm thick aluminum plate weighs 8kg per square meter, with a tensile strength of 100-280N/m. (N=Newton, mechanical unit)

b、Good durability and corrosion resistance to contact

Explore using PVDF fluorocarbon paint or powder spraying to ensure excellent weather resistance and corrosion resistance.

c、Easy to process

Adopting the process of processing before painting, aluminum plates can be processed into various geometric shapes such as flat, arc, and spherical surfaces, meeting the complex architectural design requirements.

d. The advanced electrostatic spraying technology with uniform anti coating and diverse colors ensures uniform and consistent adhesion between the paint and the aluminum plate, with diverse colors and a large selection space, which meets the requirements of architecture.

e. Not easy to stain, easy to clean and maintain the non adhesion of fluorine coating film, making it difficult to adhere pollutants to the surface, and having good self-cleaning performance.

f、Installation and construction, convenient and fast

Aluminum plates are processed in the factory according to the order drawings and installed directly on site, without the need for on-site cutting and processing. Therefore, the construction efficiency is very high, especially when facing some polygons and two-dimensional surface modeling, which reflects this characteristic.

g、Recyclable and environmentally friendly

Aluminum panels are different from decorative materials such as glass, stone, ceramics, and aluminum plastic panels, and can be 100% recycled with high residual value.

Disadvantages of aluminum veneer::

① The biggest drawback of aluminum veneer is that it is difficult to achieve a high degree of reduction in tactile sensation when replacing traditional materials.

② When using aluminum veneer as a decorative material on a large area, it is difficult to ensure the flatness of the aluminum panel and it is very easy to ripple. Therefore, it is not recommended to use aluminum veneer when the flatness of the aluminum plate is required, and it is better to choose honeycomb aluminum plate instead.

▲ If the metal plate is too thin, there will inevitably be surface unevenness

Of course, the flaws cannot be concealed. It is precisely because these aluminum veneers have these characteristics that they have such a high position in the metal sheet industry and are widely used in indoor and outdoor environments of buildings.

05. Material Technology

1、Spray treatment

The surface layer is sprayed with fluorocarbon coating, which is simple in process, but has the disadvantage of uneven color thickness distribution.

2、Roller coating treatment

After degreasing and chemical treatment, silver coating is applied; The surface flatness of this process is higher than that of the spraying process. And it can achieve effects such as wood grain, bamboo grain, and imitation stone.

3、Anodic oxidation treatment utilizes electrolysis to form a protective film on its surface, fully preserving the natural and soft metallic texture of aluminum. Make aluminum plates have higher hardness, wear resistance, adhesion performance, corrosion resistance, electrical insulation, thermal insulation, and oxidation resistance. The surface is not charged and does not collect dust. Strong self-cleaning ability, resistant to cleaning, and resistant to fingerprints. However, due to the high requirements for the grade of the substrate (5-series aluminum), the price is relatively high.

4、Film coating treatment

Made of high gloss film or illusion film, compounded with professional adhesive. Glossy and bright, with a wide variety of colors to choose from, waterproof and fireproof, excellent durability and stain resistance, and superior UV resistance.

5、Metal wire drawing treatment

Made of aluminum plate as the base material, imported diamond cloth wheels are used for surface drawing, and are subjected to various chemical treatments such as pressing and rolling coating. The exterior color is bright, uniform, and has a strong sense of fashion, giving people a strong visual impact.

6、Punching treatment

Aluminum veneer is suitable for perforation treatment and is also widely used in indoor suspended ceilings in buildings. Combined with appropriate perforation surface treatment, it can be used as a good sound-absorbing material.

▲Creative punching board

06. Aluminum veneer selection

Aluminum veneer is suitable for perforation treatment and is also widely used in indoor suspended ceilings in buildings. Combined with appropriate perforation surface treatment, it can be used as a good sound-absorbing material.

1、Observing its form

The size of aluminum veneer should be standardized and neat, with uniform thickness, flat surface, and straight plate shape. The selection of high-quality aluminum veneers is strict in terms of raw materials, with few impurities. Aluminum veneers will not deform even after being sprayed at high temperatures. Additionally, the processing equipment and management of aluminum processing all affect the flatness of aluminum veneers.

2、Smell its taste

Peel off the aluminum plate and there should be no pungent organic solvent odor.

3、 Look at the thickness

The wall thickness of high-quality aluminum veneer is uniform, and the aluminum veneer is tightly bonded. The quality and thickness of the aluminum panel can meet national standards. According to national standards, the thickness of the outer wall panel should be 4mm, and the thickness of the inner wall panel should be 3mm. The aluminum panel of the outer wall panel is significantly harder than the aluminum panel of the inner wall panel.

4、Check the spraying process

High quality aluminum veneer requires the use of the top-notch aluminum veneer spraying line, which will not allow metal and non-metallic impurities to penetrate during the spraying process. Its process accuracy is high, and the surface and inner layers have a smooth and smooth feel, without any impurities.

5、Peel test

The aluminum veneer and core layer should not be easily peeled off, and there should be a layer of brushed film on both the aluminum panel and plastic core material after peeling off.

6、Usage occasion

The surface treatment of aluminum veneers includes powder spraying, fluorocarbon spraying, etc. According to the usage environment, powder spraying can generally be used for indoor use. For outdoor use, fluorocarbon spraying is necessary to withstand various harsh natural environments and sunlight, in order to ensure that the aluminum veneers do not change color or oxidize for a long time.

7、Aluminum veneer brand

There are many aluminum veneer manufacturers in the market, and I suggest choosing a good aluminum veneer manufacturer. Because good aluminum veneer manufacturers not only ensure product quality, but also design a reasonable solution for customers to choose from based on their needs, and provide thoughtful after-sales service.

07. Cleaning and maintenance of aluminum veneer

1、Aluminum veneer cleaning

The cleaning of aluminum veneer and glass on external walls requires outdoor and high-altitude operations, and professional personnel must be sought and transportation tools such as baskets, hanging boards, and lifting platforms must be used. Cleaning method: First, rinse the surface of the aluminum plate with a large amount of water. Use a soft cloth soaked in water diluted cleaning agent to gently wipe the surface of the plate. Then, rinse the plate surface with a large amount of water to remove the dirt and check the surface. Clean the areas that have not been cleaned with cleaning agent, and then rinse the plate surface with water until all the cleaning agent is removed.

2、Aluminum veneer maintenance

The maintenance of aluminum veneer curtain walls mainly involves checking the sealing between the panels. The sealing between boards mainly relies on sealing strips and glass glue. If there is any detachment, it should be repaired and replaced in a timely manner. When repairing or replacing, do not step on the aluminum or pull on the frame as a support. This can easily wear out the aluminum veneer wall or cause accidents. Regularly check the connection between the frame and the wall. If any screws at the connection are loose, tighten them immediately. If the screw base is loose, use epoxy strong adhesive to mix a small amount of cement for sealing.

Article transferred from aluminum screening