Summary:

Aluminum sheets used in construction include various materials such as aluminum veneer, aluminum plastic sheet, and composite metal sheet. With the continuous development of aluminum panel materials for building exterior walls, more and more aluminum derived decorative panels with better visual effects and better performance and stability have been applied in recent years. In this issue, we will share the development trends of aluminum panels one by one, including aluminum single panels, metal composite panels, anodized aluminum panels, and nano ceramic aluminum panels.

01. Development of aluminum panels in the field of architectural decoration

Since the early 1980s, China's aluminum door and window and building aluminum curtain wall industries have undergone more than 20 years of development. The construction of the glass aluminum curtain wall of the Great Wall Hotel in Beijing in 1983 pioneered the development of aluminum panel curtain walls in China. After years of development, the domestic aluminum curtain wall industry has entered a stage of sustained, scientific, and stable development.

The development process is as follows:

Stage 1

Aluminum veneer

In the 1960s and 1970s, aluminum veneer withdrew from the mainstream market due to its poor decorative effect, high labor consumption, and environmental friendliness. It only appeared in shapes that cannot be achieved by composite materials such as hyperbolic, accounting for about 5% of the foreign decorative material market and appearing as a supplementary material.

Stage 2

Aluminum composite panel

Aluminum plastic board was invented in the 1960s to 1970s. From 1992 to 2007, aluminum plastic composite board became the mainstream decorative material in China, accounting for over 95%, while aluminum veneer accounted for only about 5%. Its decorative effect is good, environmental protection and energy conservation, and it quickly replaced aluminum veneer as the mainstream product.

Stage 3

Aluminum veneer

Since 2007, due to the three major fires in Shenyang, Shanghai, and Beijing, the country has raised the fire protection level of building decoration materials to Class A, and aluminum veneer has become the mainstream of building metal decoration materials

Stage 4

Non combustible grade metal composite plate

Around 2000, fire-resistant aluminum plastic composite panels were developed, followed by A-grade fire-resistant composite panels from 2008 to 2010. At the same time, metal composite materials have solved the problem of fire prevention, gradually transitioning from flame retardant and high flame retardant grades to A-grade fire prevention (successfully developed in China in 2014)

Stage 2

Nano water-based ceramic aluminum plate

Nano water-based ceramic aluminum plate is processed and formed by the gold workshop, finely polished, pre treated, sandblasted, and coated on the surface of the spraying workshop. After multiple processes, it becomes a high-performance decorative material for building interior and exterior walls. Nano ceramic aluminum plate, with application performance surpassing fluorocarbon aluminum plate, is known as the "third generation power wall aluminum plate" and is the preferred choice for owners and designers.

With the increasing demands of modern architectural art, aluminum decorative materials are constantly applying new processes and technologies to meet the higher requirements of architectural art. Next, we will analyze the advantages and characteristics of the above materials one by one.

02. Aluminum veneer

The price is relatively cheap, making it more suitable for creating hyperbolic shaped shapes.

When it comes to metal curtain walls, the first thing you should think of is aluminum veneer. Aluminum panels used in the construction and decoration industry are mainly divided into two categories: aluminum veneer and metal composite panels.

When it comes to metal curtain walls, the first thing you should think of is aluminum veneer. Aluminum panels used in the construction and decoration industry are mainly divided into two categories: aluminum veneer and metal composite panels.

Especially, the demand for hyperbolic aluminum veneer is steadily increasing year by year, and it is highly favored by engineering and designers. Double curvature aluminum veneer is an aluminum veneer product with two curved surfaces, which is processed through multiple processes such as cutting, folding, bending, welding, reinforcement, polishing, and spraying based on two different arc curvatures using aluminum veneer as the substrate.

▲Double curved plate

Application Cases

Whether in large public buildings or small individual buildings, hyperbolic aluminum panels have excellent performance in building curtain walls, outdoor landscapes, and other aspects.

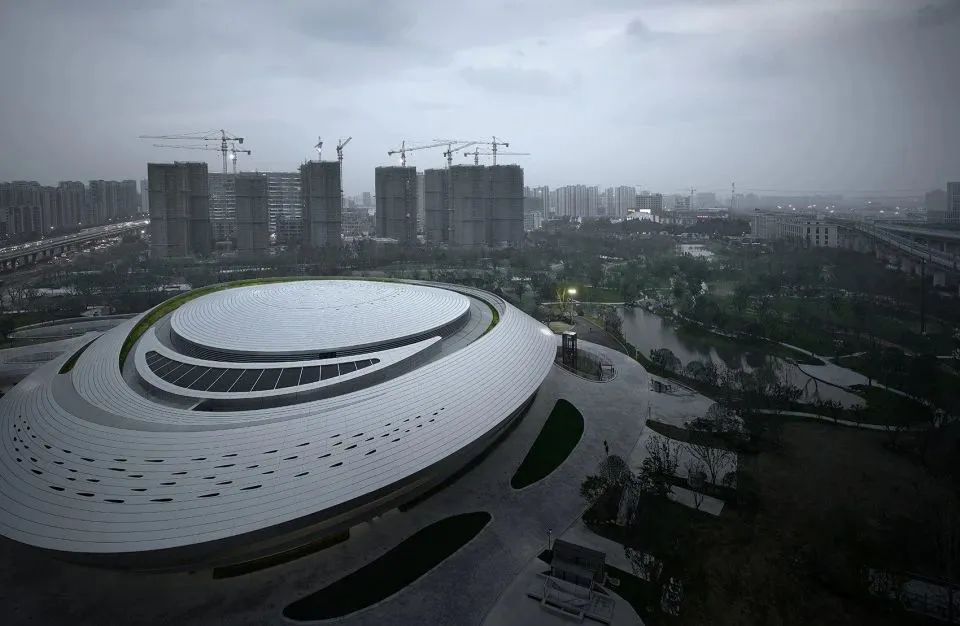

▼Hangzhou Esports Center, China

▲Realistic View of Hangzhou Esports Center @ Aoguan Architectural Vision

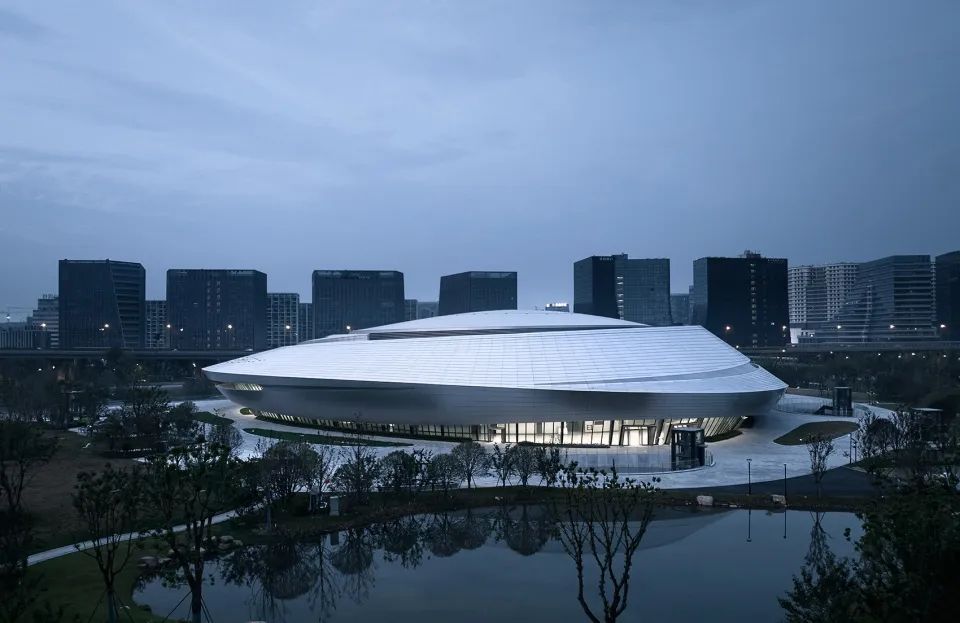

▼China National Speed Skating Center

A replica of China National Speed Skating Hall @ Populous

The "Ice Ribbon" - The facade of the China National Speed Skating Center is composed of metal aluminum panels and glass curtain walls, consisting of over 3800 pieces of glass and 6500 pieces of aluminum panels. The irregular aluminum panels account for one-third of the total aluminum panels, and the double curvature aluminum panels and double curvature glass also account for over 1400 pieces.

▲Real View of China National Speed Skating Center @ Populous

03. Metal composite plate

High cost-effectiveness, suitable for large panels, very smooth.

Aluminum composite plate is a general term: it mainly refers to the composite of aluminum plates that have undergone surface treatment as surface materials through various complex processing processes, forming aluminum composite plates on different base materials. Different composite plates are formed based on different substrates.

The common aluminum plastic board is a composite board made of aluminum and polyethylene. It not only retains the characteristics of plastic materials, but also overcomes the shortcomings of plastic materials through metal materials. It has the characteristics of light weight, strong decoration, and low cost. By filling the core material with non combustible inorganic fillers, some products can achieve a fire resistance rating of B1.

Application Cases

▼Yibin Convention and Exhibition Center Phase II

▼Shanghai Hongqiao National Convention and Exhibition Center

04. Anodized aluminum plate

Extremely decorative and weather resistant, with low maintenance costs in the later stage.

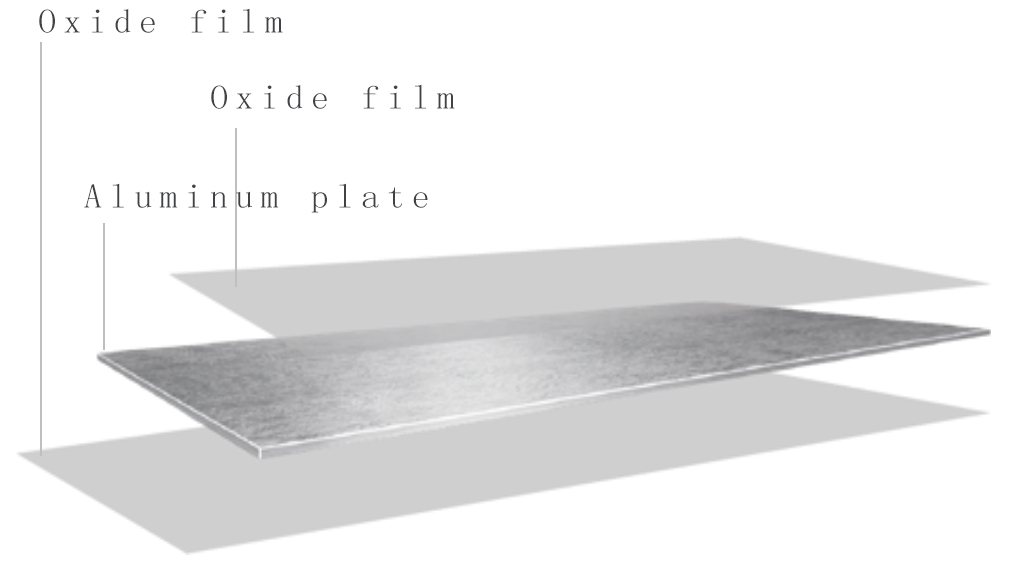

When it comes to anodized aluminum panels, designers are definitely familiar with anodizing as a highly effective surface treatment process for aluminum panels. Through the process of electrolytic oxidation, a layer of high hardness oxide film is formed on the surface of aluminum material, which has excellent wear resistance, durability, and corrosion resistance, while maintaining the natural metallic luster of aluminum material. It has been very popular among designers in recent years, and many large landmark buildings have used anodized aluminum plates as decorative materials.

▲Structural diagram of anodized aluminum plate

But expensive, the substrate is not cheap. If you want to use a large board as a whole, it is not flat enough, and there is also a color difference problem caused by the process. Anodized aluminum oxide composite plates are a good choice to address the above issues.

According to the different substrates, it can be divided into anodized honeycomb composite plates, anodized non combustible core material composite plates.

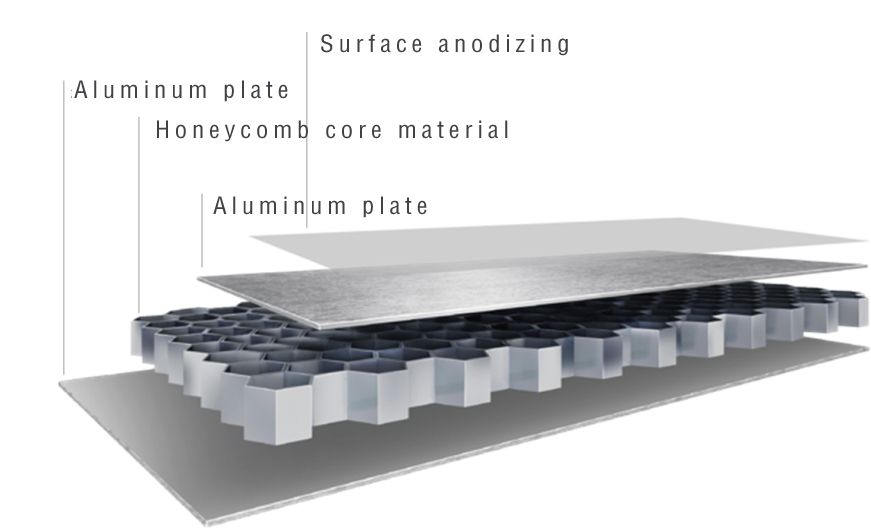

A.Anodized honeycomb composite board

Composed of panel (anodized aluminum plate), back (aluminum plate), and intermediate layer (aluminum honeycomb core material)

Material characteristics:

·A-level fire resistance, durability, and good appearance

·High strength, good flatness, suitable for large plate widths

·Lightweight board, suitable for indoor suspended ceilings

·Irregular machining but unable to punch

·Not cheap

The sheet specifications are:

Plate thickness: 10mm, 15mm, 20mm, 25mm

Aluminum plate thickness: 1.0mm, 1.2mm, 1.5mm, 2.0mm

Plate width:<1600mm Plate length: s8000mm

B. Anode oxygen non combustible core material composite board

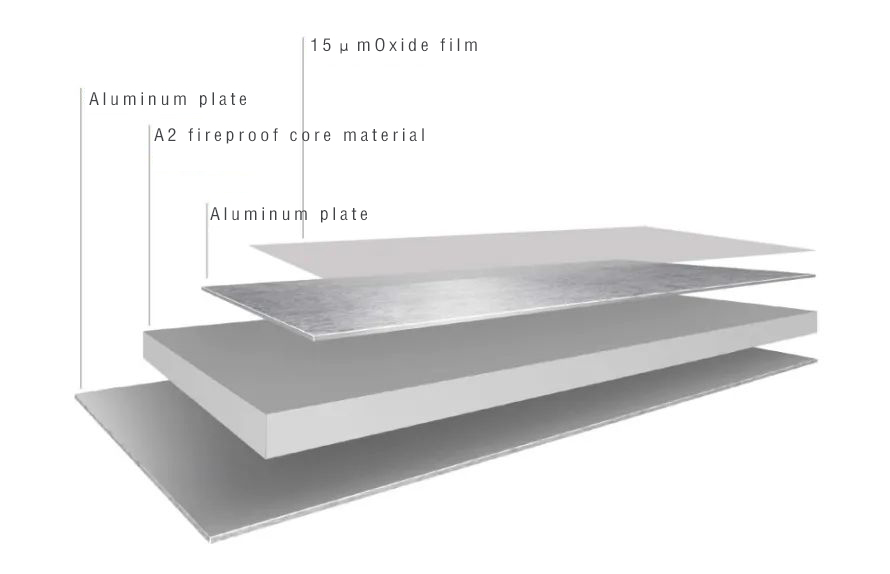

It is a "sandwich" structure that combines oxidized thick film aluminum plate, back aluminum plate, and fire-resistant core material into an integrated board through hot pressing process.

Material characteristics:

·Metallic luster, high-quality texture

·Continuous oxidation process ensures decorative effect without significant color difference

·The surface metal film is super weather resistant, antibacterial, non moldy, and easy to clean

·The surface hardness reaches 9H (sapphire grade hardness), and it is scratch resistant and wear-resistant

·Good weather resistance, 50 years without fading, with the same lifespan as the building

·The combustion performance reaches non combustible A (A2s1, do, t0) level

·It can be punched, but irregular processing is not as good as single board processing

·Suitable for large board widths, ultra flat

·High cost-effectiveness

The sheet specifications are:

Aluminum plate thickness: 3.0mm, 4.0mm, 5.0mm, 6.0mm

Plate width: 800-1550mm

Plate length: 8000mm

Application Cases

▼Jiaxing Railway Station Renovation Project

▼Nanjing Jiangbei Citizen Center

05. Nano water-based ceramic aluminum plate

Compared to the above materials, they have properties such as super wear resistance, super flame retardancy, and super weather resistance.

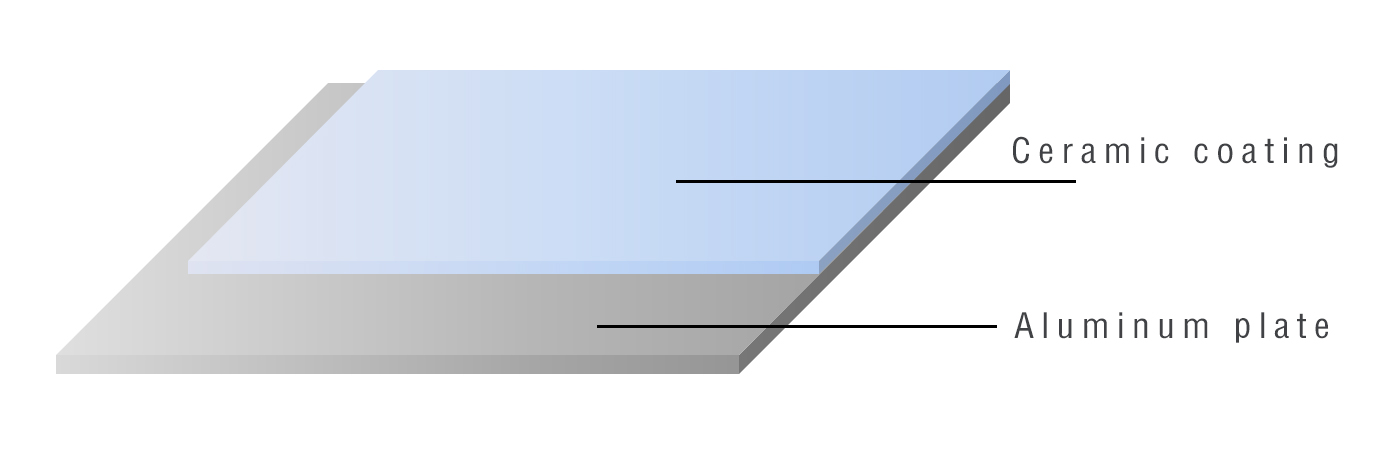

Nano water-based ceramic aluminum plate is a high-performance decorative material for building interior and exterior walls, which is coated with ceramic coating on the surface of aluminum substrate through layer by layer processes.

Ceramic coating is a kind of paint film formed at low temperature by using nano silica and siloxane as raw materials, combining inorganic super weather resistant pigments and functional inorganic fillers through the sol gel method.

:Material characteristics:

·Green and environmentally friendly materials, non-toxic and harmless

·Scratch and wear resistance, high hardness (room temperature hardness 6-9H), high wear resistance (wear resistance>20000 times)

·High strength acid, alkali, salt, solvent, corrosion resistance

·Has ultra long color retention, anti powdering, aging resistance, ultra long weather resistance (50 years), and resistance to atmospheric pollution

·Highly self-cleaning, not prone to static electricity and dust collection, purified through natural rainwater washing to maintain the cleanliness of the curtain wall facade

·A1 level fire resistance, high temperature resistance>600 ° C.

Application Cases

▼Leshan Sports Center

The exterior curtain wall adopts white and red porcelain aluminum plates, which have super strong scratch resistance, easy cleaning performance, high gloss, high hardness, and super durable weather resistance.

▼Pillar inside Nanning Airport

The pillars inside Nanning Airport are made of milk white porcelain aluminum plates with high decorative properties, which have a crystal clear enamel texture and are easy to clean, flame retardant, and high-temperature resistant.

Article transferred from aluminum screening