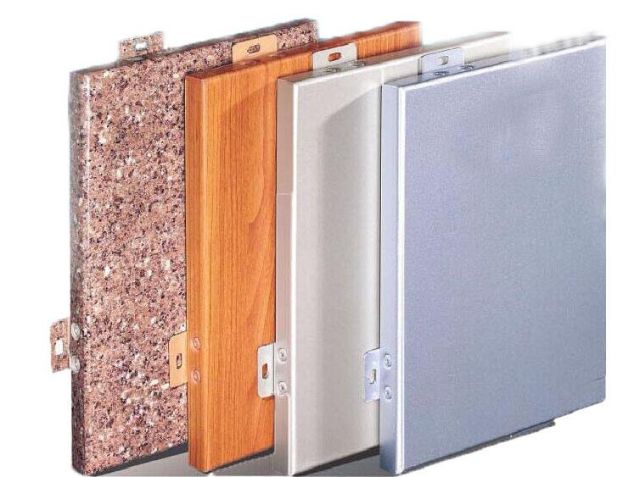

Aluminum plate has been used for curtain wall for decades. The metal plates used include aluminum veneer, aluminum-plastic composite plate and honeycomb plate. The most commonly used are aluminum veneer and aluminum plastic plate; Aluminum veneer first appeared. This paper makes a horizontal comparison between aluminum veneer and aluminum plastic plate.

2.5mm aluminum veneer:

1. Appearance quality: the flatness of the flat plate is not high, and it seems to have local concave convex.

2. It can be processed into various irregular shapes; Good spraying quality and visual quality.

3. The color difference and film thickness deviation are small, and local damage can be repaired.

4. Tensile strength: 130n / mm2

5. Mechanical elongation: 5% - 10%

6. Bending strength: 84.2 n / mm2

7. Modulus of elasticity: 70.00 n / mm2

4mm aluminum plastic plate:

1. The flatness of the flat plate is relatively high, but the machining shape is limited.

2. Due to the unstable technology of workers, there is local color difference, which is not obvious.

3. There is a certain deviation between color difference and film thickness, and local repair is not allowed after damage.

4. Tensile strength: 38-61n / mm2

5. Mechanical extension: 12% - 17%

6. Bending strength: 34 n / mm2

7. Modulus of elasticity: 26-49 n / mm2

It can be seen from the above parameters that the appearance of aluminum veneer is worse than that of aluminum plastic plate, but its mechanical properties are obviously better than that of aluminum plastic plate, and its wind pressure resistance is also better than that of aluminum plastic plate.

Aluminum veneer generally adopts 2-4mm thick AA1100 pure aluminum plate or AA3003 and other high-quality aluminum alloy plates, and most projects use 2.5mm thick AA3003 aluminum alloy plate;

Aluminum plastic composite board generally adopts 3-4mm three-layer structure (the upper and lower 0.5mm are clamped with PVC or PE).

The cost of aluminum-plastic composite plate is much lower than that of aluminum veneer. The price of 4mm aluminum plastic plate is more than 120 yuan / m2 lower than that of 2.5mm aluminum veneer.

Aluminum veneer and sheet metal processing engineering is simple, small workshops can also be done, and the quality is not stable. And the spraying process pollutes the environment, which is difficult to control.

The production process of aluminum-plastic plate is relatively complex, has a certain technical threshold, and needs an automatic production line, so it is more guaranteed in terms of environmental protection and safety.

The construction process of aluminum plastic plate and aluminum veneer is basically the same.

The biggest difference is that the aluminum-plastic plate is processed on the construction site and made into the required shape and specification on site, which has a large degree of construction freedom. The aluminum veneer is processed and formed in the manufacturer.

Due to the accuracy of the equipment, and there will be more or less accidents and access in the construction process, the construction schedule of aluminum-plastic composite plate will be higher than that of aluminum veneer from the perspective of the guarantee of project delivery date.

On the surface, aluminum veneer is aluminum metal, with better conductivity and lightning protection performance.

Alusuisseingen GmbH of Germany conducted lightning resistance tests of two materials in a military laboratory in Germany. The results show that both aluminum plastic plate and aluminum veneer can be completely protected against lightning when lightning strikes.

Therefore, both aluminum-plastic composite plate and aluminum veneer have lightning resistance.

Aluminum veneer is non combustible and its fire rating is class A. In the early stage, the fire protection grade of aluminum-plastic board was low, but with the development of aluminum-plastic board technology, the fire protection performance was greatly improved by adding non-toxic and flame retardant materials into its PE. It can make grade B1 products to meet the needs of engineering fire protection, so the fire protection grade of aluminum veneer is high!