Preface

The external wall maintenance of curtain wall four buildings is not load-bearing and looks like a curtain. It is a light wall commonly used in modern large and high-rise buildings. In this phase, we will learn about a curtain wall.

Curtain walls can be divided into building curtain walls, component building curtain walls, unit curtain walls, glass curtain walls, stone curtain walls, and metal plate curtain walls. Full glass curtain wall, point supported glass curtain wall, etc. The metal plate curtain wall is divided into stainless steel curtain wall, aluminum plastic plate curtain wall, aluminum veneer curtain wall, etc.

In this issue, we learned about aluminum veneer curtain wall and aluminum veneer scale curtain wall.

01·Product specification and classification

Classification

Aluminum veneer curtain wall is a curtain wall made of aluminum plates. The structure of aluminum veneer is mainly composed of panel, reinforcing rib, lug and other components, and the back of the panel can also be filled with insulating mineral wool.

The thickness of aluminum veneer is mainly 1.5mm, 2.0mm, 2.5mm and 3.0mm. The cost of aluminum veneer with thickness less than or greater than this is increased on the basis of normal cost. The thickness of aluminum curtain wallboard mainly adopts 2.0mm and 2.5mm 3.0mm plates. There are 4.0mm and 5.0mm thick aluminum plates on the market.。

Due to the high plasticity of aluminum veneer, aluminum veneer curtain wall is mainly used for the interior and exterior decoration of some large shopping malls, the decoration of lobby facades and columns of large hotels, elevated corridors, pedestrian overpasses, elevator edging, balcony packaging, advertising signs, indoor special-shaped ceiling and other decoration.

02· Material characteristics

Performance

1、High plasticity. Due to the hardness comparison of aluminum, it has good metal ductility, and can shape different shapes at will. Besides, the production of aluminum veneer for curtain wall is simple, and the installation steps are simple.

2、It has corrosion resistance. Weathering resistance, effective resistance to ultraviolet rays, and no fear of wind and sun. The aluminum veneer treated with fluorocarbon paint can remain colorfast for up to 25 years.

3、Green and environment-friendly, aluminum veneer curtain wall panel is a recyclable product, which is conducive to environmental protection and is advocated by the state

4、Light weight, only one fifth of marble and one third of glass curtain wall, greatly reduces the load of building structure and foundation, and has low maintenance cost and high cost performance.

5、Good thermal insulation and fire resistance. Aluminum veneer curtain wall can meet the needs of sound insulation and heat preservation through punching and installing sound absorbent cotton; The aluminum veneer curtain wall is made of metal and is one of the natural fire protection building materials. After testing, the fire protection rating of the aluminum panel is as high as A2, and the melting point is as high as 660 degrees. It is one of the excellent fire protection building materials.

6、The sound insulation effect is good. According to the test, the sound insulation of aluminum veneer products is up to 29-32dB, which is equivalent to the sound insulation effect of solid brick walls. In infrastructure projects, it is often used as the airport sound barrier to effectively solve the impact of traffic noise on residents.

03·Construction and installation nodes

Install nobe

A、Main machines and tools

Electric welding machine, cutting machine, electric hand drill, rivet gun, barrel type glue injection gun. Portable air pressure washer, pulley, palm rope, nylon rope, screwdriver, tool knife, plasterer, etc.

B、Process flow

Surveying and setting out → checking construction drawings → construction of embedded plates → construction of steel frames → adjustment → full welding of frames → anti-corrosion treatment → concealed acceptance → plate inspection → plate installation → cleaning → acceptance

1、Snap line for positioning

①According to the detailed drawing of curtain wall division and elevation points, the location of entrance and exit lines and axes. Determine the curtain wall plane on the main body with heavy hammer, steel wire measuring instrument, level gauge and other tools. The datum lines such as column grids and corners shall be adjusted and retested with theodolite;

②The measurement and setting out of the partition axis of the curtain wall shall be coordinated with the measurement and setting out of the main structure to avoid the accumulation of errors. If the error is greater than the specified allowable deviation (including the vertical deviation value), the axis of the curtain wall shall be adjusted appropriately to meet the structural requirements of the curtain wall after obtaining the consent of Party A, the supervisor and the designer;

③The measurement of high-rise buildings shall be carried out regularly every day when the wind force is not greater than Grade IV;

2、Embedded parts construction

Since the main structure has been completed, but the embedded parts connecting the curtain wall and the main body have not been made, the fabrication and installation of the later embedded parts are required. The post embedded parts shall be connected with the main civil structure. The iron plate behind the wall shall be welded with the bolt. The distance between the screw and the edge of the concrete shall be ≥ 250mm. The nut shall be welded to prevent loosening. After welding, the anti-corrosion treatment shall be carried out;

The post embedded parts shall be reliably connected with the main structure with anchor bolts.

3、 Keel installation

①Fix the main keel with the connecting support first, then connect it with the angle steel support of the embedded parts of the main body that have been welded first, adjust and fix it, electric welding first, then full welding. The quality of keel construction directly affects the dry hanging quality of aluminum veneer, so the installation quality of keel should be strictly controlled;

②The horizontal keel shall be installed and the levelness shall be strictly controlled. Since the levelness directly affects the quality of the transverse seam of the aluminum veneer, the horizontal tolerance shall be controlled within ± 1mm, and full welding shall be carried out after adjustment.

4、After the welding of the steel frame with anti-corrosion treatment, it shall be coated with two coats of antirust paint.

5、Concealed acceptance

①Check the installation of the connection point between the component and the main structure;

②Check the connection form and welding quality between steel frames;

③Check whether the lightning protection grounding connection is correct and effective, and whether it can meet the design lightning protection requirements;

④The pulling force of anchor bolt shall be tested, and the aluminum veneer shall be installed after passing the test.

6、Installation and construction of aluminum veneer

①After entering the site, the aluminum veneer shall be inspected in strict accordance with the specification requirements and placed by product number.

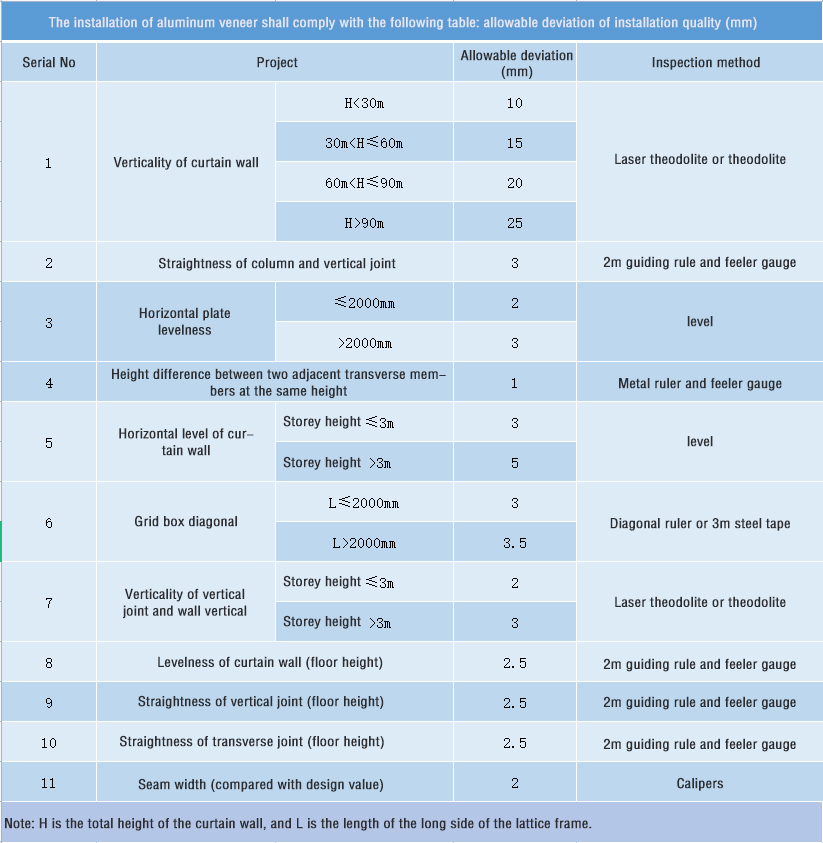

②Before the installation of aluminum veneer, thin steel wire shall be used to pull the control line to ensure the installation accuracy. The installation of aluminum veneer shall comply with the following table:

7、Sealant construction

①Before gluing, the protective tape shall be pasted around the board to prevent contamination, and the dust in the seams around the board shall be cleaned with a steel brush;

②The glue thickness shall be 6-8mm, and the glue surface shall be smooth and beautiful without wrinkles.

8、Aluminum veneer surface cleaning

After the installation of aluminum veneer, it shall be checked, repaired and cleaned. When removing the shelf, attention shall be paid to the protection of finished products.

C、Precautions:

1、Anti deformation ability: calculate each important part of the curtain wall system with scientific mechanics, not only considering the effects of wind pressure, dead weight, earthquake, temperature and other effects, but also carefully checking embedded parts, connection systems, keel systems, panels and fasteners to ensure the safety of the curtain wall.

2、 Plate fixing method: fixed distance compaction shall be adopted to ensure the flatness of the curtain wall surface. Because the stress of each fixed point of the plate is inconsistent, the deformation of the surface material will affect the exterior decoration effect.

3、 Floating connection is adopted for plates: it not only ensures the resilience of the curtain wall after deformation, but also ensures the integrity of the curtain wall, which will not cause deformation of the curtain wall due to force, and avoid the occurrence of bulge or depression on the surface of the curtain wall.

4、Reinforcement measures shall be taken for the edge removal of composite surface material: since the folding edge of composite panel material only retains the thickness of the front plate, the thickness becomes thinner and the strength decreases, reinforcement measures shall be taken.

5、The materials selected shall conform to the specifications, standards and design requirements: the quality of materials on the market is also different at present. The selection of qualified materials is the basis for ensuring the quality of curtain walls. Strict inspection methods must be adopted to ensure the quality of materials.

6、The waterproof sealing shall be reasonable: different sealing methods have different prices, so appropriate sealing methods shall be selected for the project to ensure the function and exterior decoration effect of the curtain wall. The available methods are: structural waterproof, internal waterproof, sealant sealing.

The scale aluminum veneer belongs to the profiled aluminum veneer, also called profiled scale aluminum veneer. It is mainly applied to the facades of various buildings.

The external facade of aluminum veneer with special-shaped scales can also make dynamic effects: the static aluminum veneer scales benefit from the geometric scale aluminum veneer without angle combination, thus presenting a dynamic effect.

04· Application Cases

Application case

Chongqing Luyuejiang City City Reception Hall was designed by the international architecture firm 10 Design. The total construction area of this project is about 9000 square meters. The main building with five floors in total is located on the steep hillside of Chongqing, China.

▲Reflection in water

▲Close up view of the project

▲Sparkling facade

▲Project Appearance

The scale curtain wall is composed of 8527 angled perforated metal plates: geometric scale aluminum veneer with different angles. The facade aluminum veneer is composed of six aluminum veneer scales with different specifications and angles and 11 304 stainless steel connectors with different angles.

▲Glass screen wall

▲Flake curtain wall

It is in this way that the facade can create a dynamic beauty of ups and downs from different angles, and create a unique and dynamic shape for the project.

Located in the Binhai New Area on the east coast of Tianjin, Shimao · Spray Art Museum, designed by Beijing Riqing Architecture, is a diversified living area integrating entertainment, relaxation, education, entertainment and culture.

▲You can see different views from the terrace

The architecture takes the spray as the image and creates a sea mirror image, forming a dialogue system between architecture and nature.

▲The art gallery has three outdoor terraces

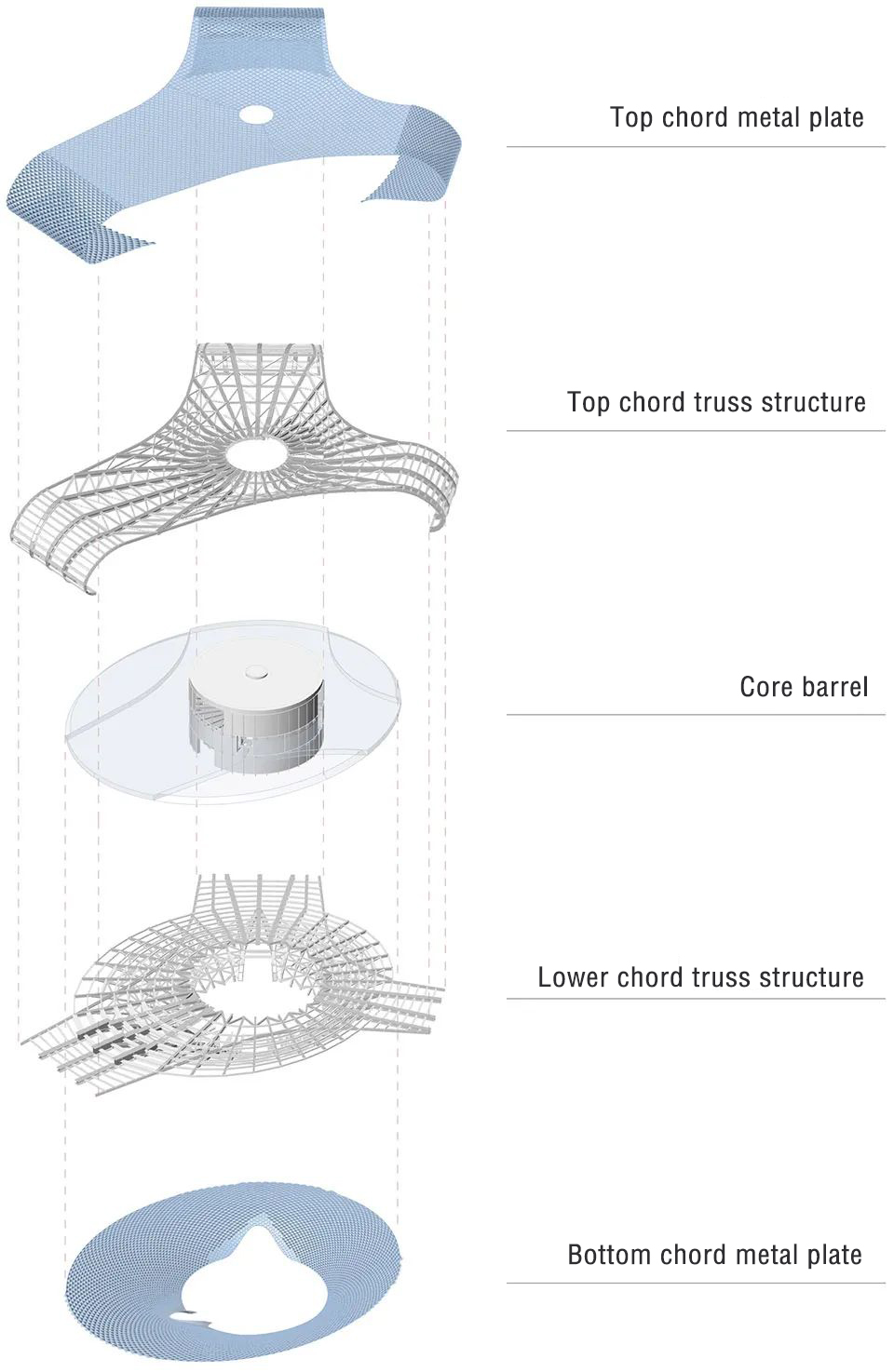

▲Structure breakdown diagram

The skin of the building is designed with integrated parameterization, and the fish scale aluminum plates are arranged with subtle changes, so that the facade reflects the sunlight at different times from all angles. The diffuse reflection of the pool around the building on the light is projected onto the scale facade again, making the building show rich changes in light and shadow.

▲Facade scale details

With BIM technology, more than 13000 pieces of aluminum plates of different specifications are transformed and fitted on the facade, realizing a two-way spiral texture with rhythmic changes.

The Oriental Oasis Park, where the Shanghai Public Security Education Training Base is located, is located on the east bank of the mountain lake in Zhujiajiao Town, Qingpu District. It is the only large-scale park in Shanghai that integrates outward bound training, youth social practice, team activities and leisure tourism.

▲Night view of the south facade of the building

▲View from the southwest side of the base street

By gmp. Feng Designed by Gekang, Marge and partner architects, the facade and roof of the whole building complex are covered with rhombic scale aluminum plates. Only the entrances on the north and south sides and the joints between the buildings are glass curtain walls.

▲Overhanging structure of upper building

▲View of single building junction

The size of perforated aluminum plate of diamond shaped curtain wall varies with the elevation, and the maximum diagonal line can reach 2m. The complete coverage of complex geometric facades is achieved through parametric calculation, and the modular and prefabricated structures ensure the economic intensification of construction methods and costs.

Also, the Malacca Performance Theatre is located on the coast of Malacca City. After five years of creative design and construction, it covers an area of 4.75 hectares and can accommodate more than 2000 people. It is the first theater in Malaysia with a 360 degree rotating auditorium.

▲Northwest facade of the building

▲South facade of the building - LED performance

The building is the simplest geometric shape, but it is changing all the time. The inner surface of the building is a blue painted wall, and the outer surface is mainly composed of more than 50000 white scales of diamond shaped metal aluminum plates. The outer facade forms a unit module with the curtain wall glass, and finally forms a huge LED display screen by splicing.

▲Building material details

A number of arc bodies recessed in the top are wrapped by more than 12000 pieces of 1800 square meters of special-shaped curved glass curtain wall, which can reflect the surrounding environment as well as form a weather by virtue of LED changes.

It breaks through the traditional architectural design category and is an innovation in "concept". The architecture has its own "life". It is deeply cultivated, mysterious and restrained. There is huge energy behind the calm and dignified.

Data from Material Commune