What is aluminum-plastic composite plate?

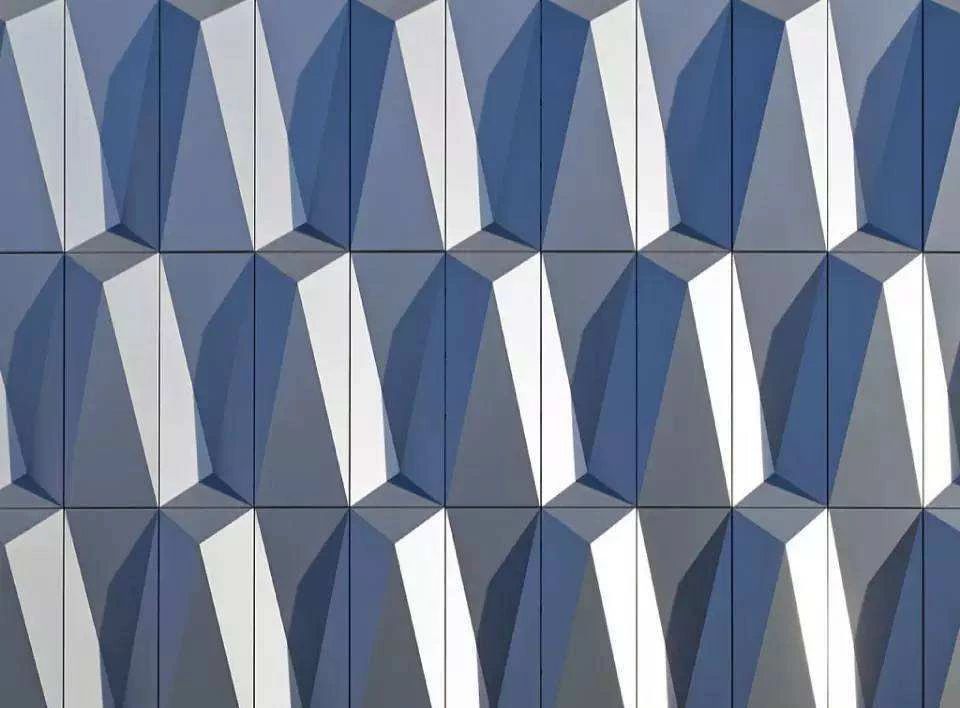

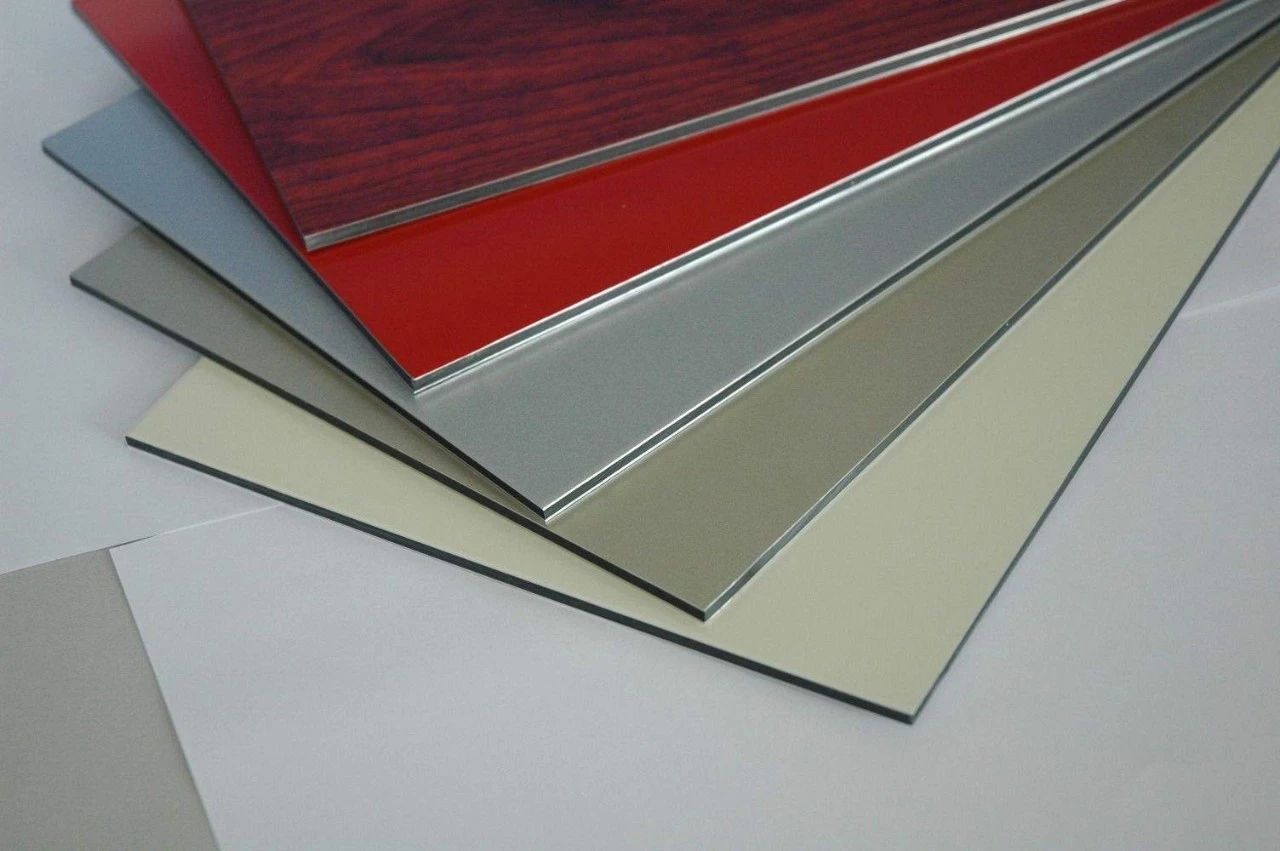

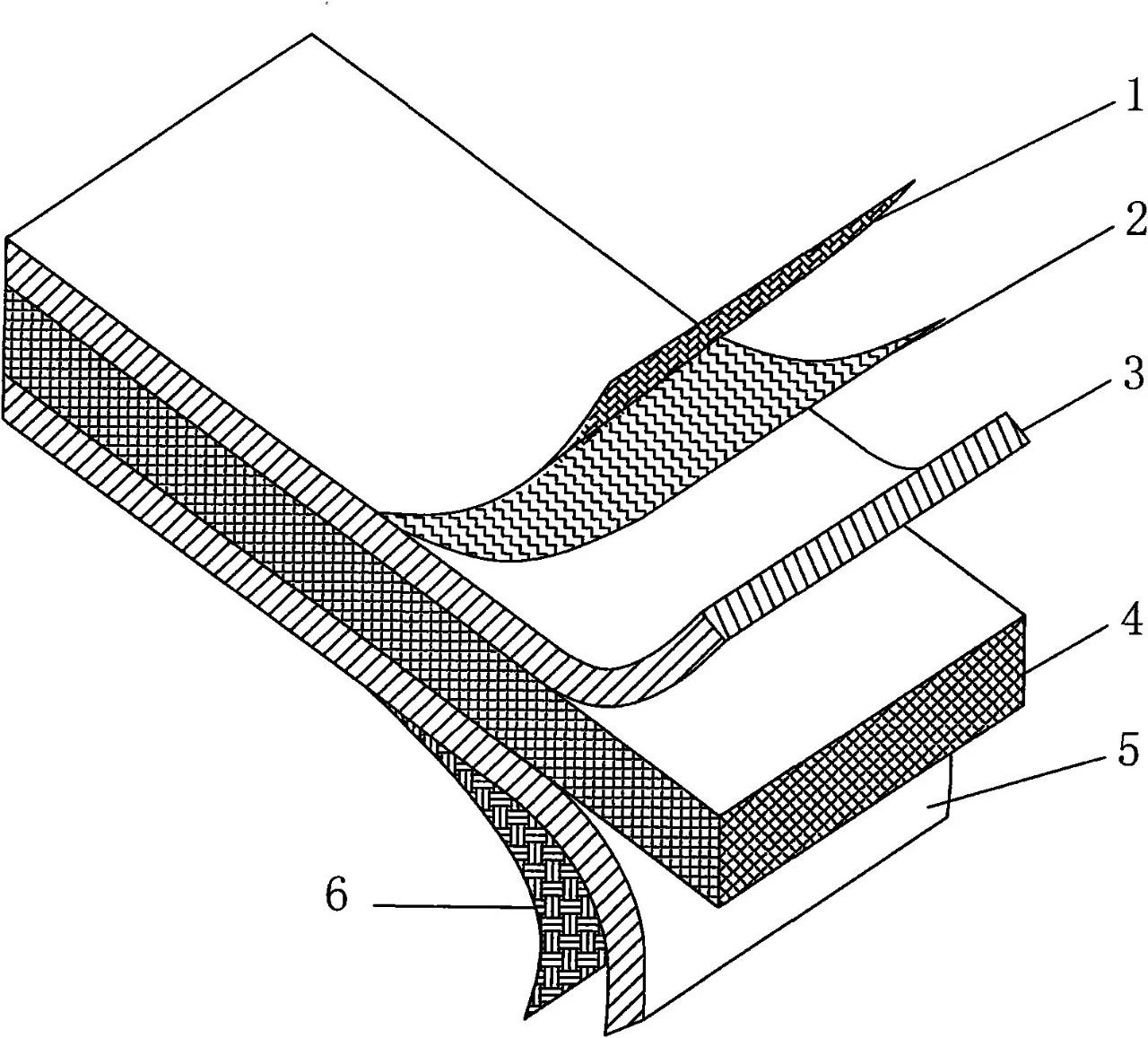

As a new decorative material, aluminum-plastic composite plate (also known as aluminum-plastic plate) is a composite material processed on special aluminum-plastic plate production equipment with chemically treated coated aluminum plate as the surface material and polyethylene plastic or high mineral as the core material. It is composed of two materials (metal and non-metal) with different properties. It not only retains the main characteristics of the original constituent materials (metal aluminum and non-metal polyethylene plastic), but also overcomes the shortcomings of the original constituent materials, so as to obtain many excellent material properties, such as luxury, colorful decoration, weather resistance, corrosion resistance, impact resistance, easy processing and molding, easy handling and installation. Therefore, aluminum-plastic composite panels are widely used in all aspects of architectural decoration and have become one of the representatives of metal curtain walls. Since it was introduced from Germany to China in the late 1980s and early 1990s, it has been rapidly favored by people for its economy, diversity of selectable colors, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality.

PERFORMANCE & CHARACTER

Aluminum plastic composite plate is widely used in domestic buildings. Since it was introduced from Germany to China in the late 1980s and early 1990s, it has been rapidly favored by people because of its economy, diversity, easy construction, easy processing, and good fire resistance. Its performance is as follows:

(1) Strong peel strength: the aluminum-plastic plate adopts a new process, which improves the peel strength, the most critical technical index of the aluminum-plastic composite plate, to an excellent state, and improves the flatness, weather resistance and other properties of the aluminum-plastic composite plate accordingly.

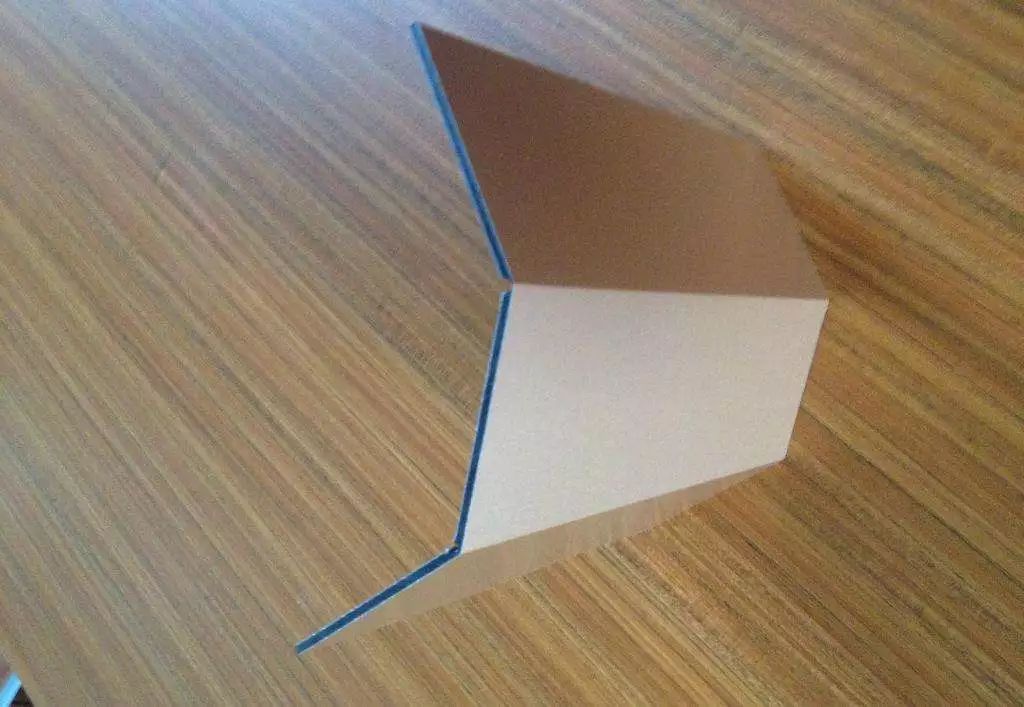

(2) The material is easy to process: the weight of the aluminum-plastic plate per square meter is only about 3.5 ~ 5.5kg, which is easy to carry. It has excellent constructability. It can be cut, cut, planed and changed with a simple woodworking tool. It can also be cold bent, cold cut, riveted, screw connected or glued. Because of its simple installation, the construction cost can be reduced.

(3) Impact resistance: it has strong impact resistance, high toughness, no damage to finish paint due to bending, strong impact resistance, and will not cause wear due to sandstorm impact in areas with large sandstorms.

(4) Weather resistance: because of the unique advantages of PVDF fluorocarbon paint in weather resistance, it will not damage the beautiful appearance in hot sunshine or cold snow, and can be used for 20 years.

(5) Uniform coating and diverse colors: after chemical treatment and application of Henkel film technology, the adhesion between paint and aluminum-plastic plate is uniform and diverse.

(6) Excellent fire resistance: the middle of the aluminum-plastic plate is flame-retardant PE plastic core material, and the two sides are extremely difficult to burn aluminum layers. Therefore, it is a safe fire-proof material and meets the fire resistance requirements of building laws.

TECHNIC & CATEGORY

There are many kinds of aluminum-plastic plates and they are a new type of material. So far, there is no unified classification method, which is usually classified according to product functions, surface decoration effects and uses.

(1) Fireproof board: flame retardant core material shall be selected, and the combustion performance of the product shall reach the flame retardant grade (B1) or non combustible grade (a).

(2) Antibacterial and mildew proof aluminum-plastic plate: paint with antibacterial and bactericidal effect is coated on the aluminum-plastic plate.

(3) Antistatic aluminum-plastic plate: the aluminum-plastic plate is coated with antistatic paint, so it is not easy to generate static electricity and the dust in the air is not easy to adhere to its surface.

Classification by surface decoration effect:

(1) Coated decorative aluminum-plastic plate: various decorative coatings are coated on the surface of aluminum plate. Fluorocarbon, polyester and acrylic coatings are commonly used.

(2) Oxidized colored aluminum-plastic plate: aluminum alloy panel is timely processed by anodic oxidation, with red, bronze and other colors.

(3) Film coated decorative composite plate: according to the set process conditions, the color pattern film is bonded to the aluminum plate coated with primer and directly pasted to the degreased aluminum plate by the action of adhesive.

(4) Color printed aluminum-plastic plate: different patterns are printed on the transfer paper with color ink through computer Phototypesetting printing technology, and then various natural patterns are indirectly copied on the aluminum-plastic plate through thermal transfer technology.

(5) Wiredrawing aluminum-plastic plate: aluminum alloy panel with wiredrawing surface is used, and gold and silver wiredrawing products are common.

(6) Mirror aluminum plastic plate: the surface of the aluminum alloy panel is polished, just like a mirror.

Classified by use:

(1) Aluminum plastic plate for building curtain wall: the minimum thickness of upper and lower aluminum plates shall not be less than 0.50mm, and the total thickness shall not be less than 4mm. Aluminum materials shall meet the requirements of GB / T 3880. Generally, 3000 / 5000 series aluminum alloy plates shall be used, and fluorocarbon resin coating shall be used for coating.

(2) Aluminum plastic plate for exterior wall decoration and advertising: the upper and lower aluminum plates shall be made of antirust aluminum with a thickness of not less than 0.20mm and a total thickness of not less than 4mm. The coating is generally fluorocarbon coating or polyester coating.

(3) Indoor aluminum-plastic plate: the upper and lower aluminum plates are generally 0.20mm thick, with a minimum thickness of no less than 0.10mm and a total thickness of 3mm. The coating is polyester coating or acrylic coating.

COMMON PARAMETERS

Aluminum plastic plate for building curtain wall: the minimum thickness of the upper and lower aluminum plates shall not be less than 0.50mm, and the total thickness shall not be less than 4mm. The coating is generally fluorocarbon resin coating. Outdoor wall decoration and advertising aluminum-plastic plate: the thickness of upper and lower aluminum plates shall not be less than 0.20mm, and the total thickness shall not be less than 4mm. The coating is generally fluorocarbon coating or polyester coating. Indoor aluminum-plastic plate: the upper and lower aluminum plates are generally 0.20mm thick and the minimum thickness is not less than 0.1mm. Generally 3 mm polyester coating or acrylic coating.

The total thickness of commonly used aluminum-plastic plate in the market: 3mm, 4mm, 6mm;

Width: 1220mm, 1500mm;

Length: 1000mm, 2440mm, 3000mm, 4000mm, 6000mm.

Size: 1220mm × 2440mm is the standard plate.

CONSTRUCTION INTRO

Aluminum plastic plate wall installation mainly includes wood base adhesion and dry hanging.

Pasting is applicable indoors: install keel → install base plate → paste aluminum-plastic plate on base plate with universal adhesive → apply glass adhesive to joints → tear protective film → finish (note that the base plate on the outer wall should be waterproof, and the glass adhesive should be weather resistant adhesive)

Dry hanging is applicable to building exterior walls: welding the base skeleton (angle iron or square pipe) → folding the aluminum-plastic plate according to the angle code or hanging hook (angle aluminum or special accessories) → fixing the aluminum-plastic plate on the base skeleton with through-hole screws → installing filler strips at the joints → applying glass glue → tearing the protective film → completing (Note: the glass glue of the accident wall should be weather resistant glue)

DESIGN KEY POINTS

The surface color and texture of the aluminum-plastic composite board can be selected. At the same time, different core materials correspond to different performance fire ratings. Designers can choose them according to different situations. In addition, there are various metal plastic composite plates with different surface metals combined with high-pressure low density polyethylene (LDPE) core materials in the market, such as copper plastic composite plates and stainless steel plastic composite plates, whose principles are the same. The main purpose is to composite the different advantages of the two materials, improve the overall performance, and save the surface metal cost. Designers can draw inferences from one instance.

Transfer from network