Aluminum plates used in buildings include single-layer aluminum plates, composite aluminum plates and other materials. Generally, they often refer to single-layer aluminum plates (also called single aluminum plates or pure aluminum plates). They are mostly used in architectural decoration projects. Aluminum plate curtain wall is a form of four curtain walls. In short, it is made of aluminum plates instead of glass. Aluminum plate curtain walls are mostly used for wall shielding and non lighting walls, and single-layer aluminum plate has been used for aluminum plate curtain walls in foreign countries.

What is aluminum curtain wall?

The building curtain wall market is increasingly rich in products, forming a diversified market structure based on aluminum, plastic, wood and steel. More new products will appear in the application of new materials and technologies. Compared with other industries, aluminum curtain wall products have less product differences and more fierce competition.

The appearance of aluminum curtain wall can be diversified, and can be perfectly combined with glass curtain wall materials and stone curtain wall materials. Its self weight is light, only one-fifth of marble and one-third of glass curtain wall, which greatly reduces the load of building structure and foundation, and has low maintenance cost and high performance price ratio.

The surface of aluminum curtain wall is generally treated with fluorocarbon spraying after chrome and other pretreatment. Fluorocarbon coating has excellent corrosion resistance and weather resistance, can resist acid rain, salt mist and various air pollutants, has excellent cold and heat resistance, can resist strong ultraviolet radiation, can maintain long-term color fastness, and has long service life.

Affected by the energy conservation policy, the product structure of domestic aluminum curtain wall will be greatly changed. Aluminum alloy curtain walls are still dominated by open frame, hidden frame and aluminum plate curtain walls. Unit curtain walls have good development prospects in large and medium-sized cities. Aluminum alloy double-layer, intelligent and sunshade curtain walls are gradually mature and improved. The share of aluminum curtain wall in the building curtain wall market will remain above 55%, and the product structure will change greatly. Affected by the national building energy conservation policy and the energy crisis, the proportion of energy-saving and environmental friendly aluminum curtain walls will be greatly increased.

Art aluminum curtain wall

Emerson Los Angeles

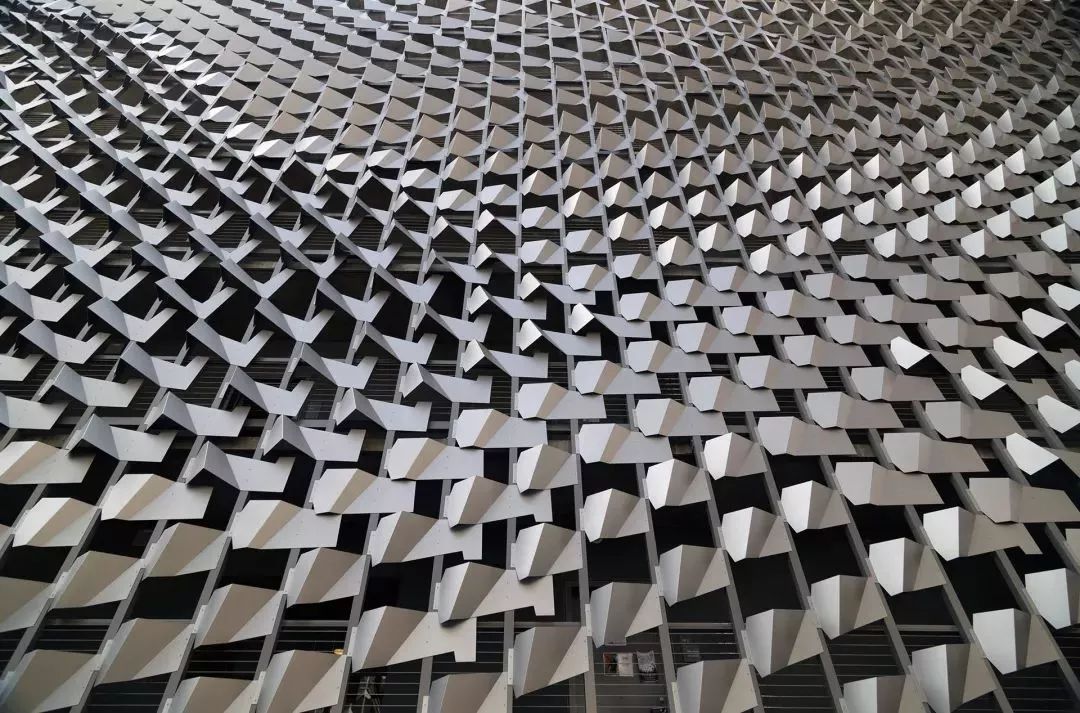

Emerson Los Angeles was completed in 2014. The design integrates housing, administrative office buildings and teaching facilities in the city center. As the most unique element of the project, the building adopts a customized metal panel system.

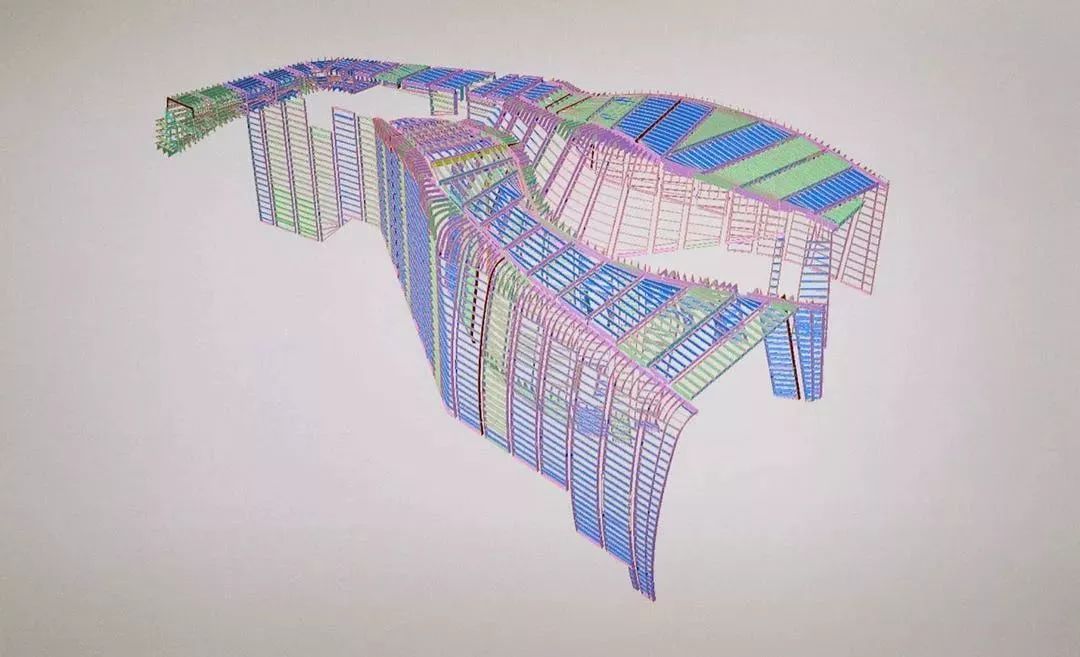

These screens and panels are composed of 17 different folding aluminum components, which provide shading effect and required concealment. It is made using 3D models and assembled with the curvature designed by morphosis. This 8-layer sunscreen layer was made using a computational script to determine the final geometry to mask the internal facade. The dynamic surface is formed by a script program, which takes into account the location of elms in the courtyard on the fifth floor and the curvature of the teaching building.

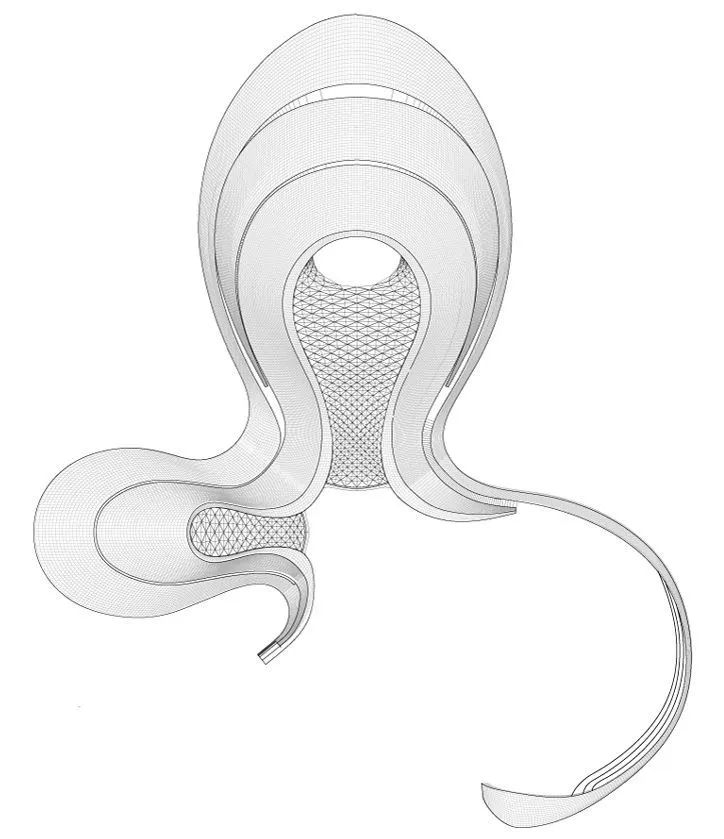

Harbin Opera House

Harbin theater has become the focus of the Harbin cultural island international competition. In response to the strength and spirit of the northern city's wilderness and cold climate, the building is integrated with the surrounding terrain. The opera house is part of the overall planning and wetland landscape along the Songhua River. This winding building has become a local landmark for tourists to imagine themselves as performers.

Tourists are encouraged to climb the granite steps to the metal roof of the Grand Theater, which can be seen from the ground. The roof terrace can enjoy the surrounding scenery of the Songhua River and the city skyline. The outer wall panel is a series of smooth white aluminum panels made by Shenyang Yuanda, which evokes the poetic charm of soft and sharp edges and surfaces.

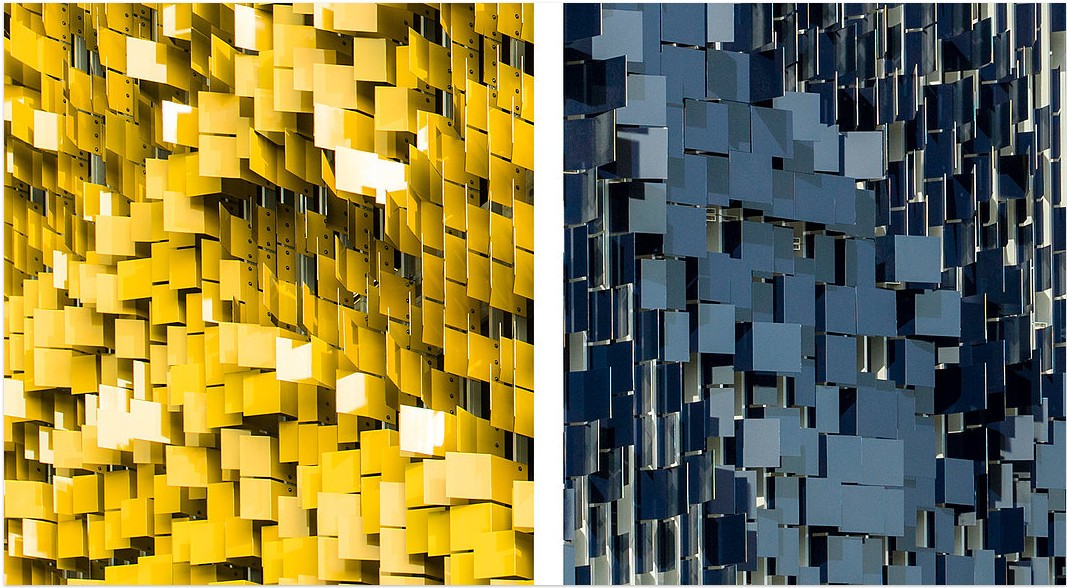

Curtain wall of parking lot of a hospital in Indianapolis

The project creates a dynamic facade system for the facade of the parking lot, which provides unique visual experience for observers according to their favorable position and the speed at which they move in the field. In this way, pedestrians and people near the hospital will experience obvious and mottled changes in color and transparency when moving, while drivers driving along the streets of Western Michigan will experience a faster and gradient color change.

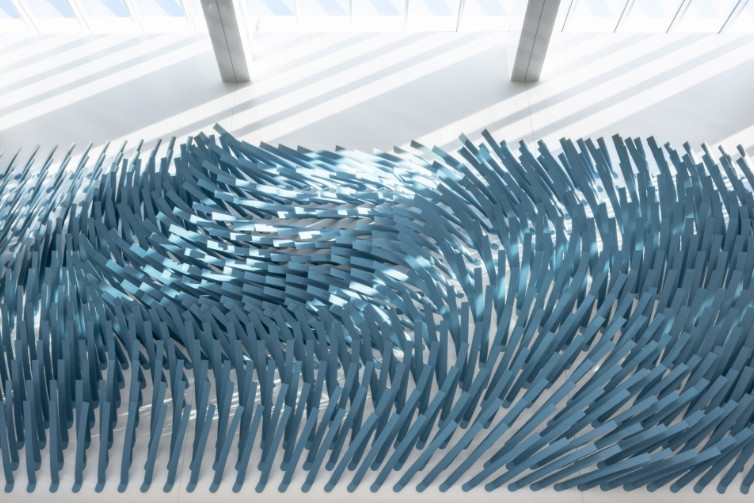

Field Lines

This large sculpture is located at the newly expanded O'Hare Airport transportation hub, which means a representative of dynamic airflow, oscillating under stable and turbulent wind conditions. This work is entirely composed of shaped aluminum plates, and the carved shape reminds people of the flow of the breeze in the field.

Comparison of composite aluminum sheet and aluminum alloy veneer

Texture of material

Composite aluminum plate: two layers of 0.5mm thick pure aluminum plates with PVC or PEC plastic sandwiched between them are rolled and heat bonded;

Aluminum alloy veneer: 2-3mm aluminum alloy veneer.

Fluorocarbon coating

Composite aluminum plate: it is made by one-time roll printing, and the coating thickness is generally 20 μ m;

Aluminum alloy veneer: it is sprayed twice or three times, and the coating thickness is generally 30-40 μ m.

colour

Composite aluminum plate:a variety of colors can be selected. The color system is mainly divided into monochrome system and phantom color system. The surface of patented color products is attached with a film layer, which has excellent durability and good color identity;

Aluminum alloy veneer: color can be selected arbitrarily according to the design and the owner's requirements.

life

Composite aluminum plate:domestic plate for about 10 years, imported plate for more than 20 years in color and strength, maintenance free;

Aluminum alloy veneer:up to 15 years, mostly deformed by climate and wind pressure, and the color of the veneer is spent.

Airtightness

Composite aluminum plate:open at four corners;

Aluminum alloy veneer:four corners are welded tightly.

Wind resistance

Composite aluminum plate: the wind pressure resistance deformation is small, and the wind pressure resistance strength of imported composite plate is very high;

Aluminum alloy veneer: it has high resistance to wind pressure deformation and is easy to deform.

Temperature denaturation resistance

Composite aluminum plate:the composite plate processed by ordinary gluing process has a large difference in expansion coefficient between aluminum plate and plastic, which is prone to foaming and peeling;

Aluminum alloy veneer:the same material has no effect on the wallboard itself when the temperature changes.

Lightning resistance

Composite aluminum plate:it is not lightning resistant, strong current is difficult to be grounded through composite aluminum plate, and 0.5mm thick aluminum plate will be broken down;

Aluminum alloy veneer:as a good conductor of electricity, it can quickly transmit the huge lightning current to the underground through the building grounding system.

Processability

Composite aluminum plate:it can be processed on site, and can cope with the size change caused by site construction errors;

Aluminum alloy veneer:made by the manufacturer, it has poor adaptability to site construction errors and high requirements for secondary design.

Yield

Composite aluminum plate:generally 80% - 95%;

Aluminum alloy veneer:100%.

Yield

Composite aluminum plate:manually plane the groove on site. If the depth of the groove is not well controlled, it will damage the outer aluminum plate, break the bending, and scrap the product. The yield is generally 96% - 98%;

Aluminum alloy veneer:100%。

Construction quality:

Composite aluminum plate:as most wallboards are processed on site, poor quality control conditions, Jerry building and shoddy materials are easy to occur in this link, and the quality of wallboards will affect the construction quality;

Aluminum alloy veneer:the manufacturer controls the production quality according to international standards, and the quality of wall panels is reliable, which provides the premise for ensuring the construction quality.

Environmental protection:

Composite aluminum plate: related to the selection of core materials. Generally, the core materials will produce harmful gases in case of high temperature, which is not fireproof and difficult to recycle;

Aluminum alloy veneer:fireproof, easy to recycle and not polluting the environment.

Scope of application:

Composite aluminum plate:applicable to curtain wall engineering;

Aluminum alloy veneer:suitable for facade decoration, elevated corridor, pedestrian overpass and ground floor curtain wall.

Key points of curtain wall scheme design

The focus of curtain wall scheme design is still "design". A design work full of spirituality is often the most moving, so designers must have a high aesthetic standard. Many party a even completely entrusted the design of the building facade to the curtain wall company, which is also a high trust in the curtain wall unit on the one hand and a great problem for the curtain wall designer on the other. Although each curtain wall designer has different views on the structure of the curtain wall, his overall grasp of the building shape has risen to the height of architectural design. In addition, with the adjustment of the scheme, For curtain wall designers, the invisible increase in workload is unpredictable.

Curtain wall scheme designers play the role between architects and curtain wall structural engineers. They need to express the expected facade shape in the form of curtain walls according to the original building construction drawings and structural construction drawings, in combination with the developer's expectations and positioning for the project, and by integrating local customs and aesthetic habits.

As architectural designers and structural designers have built the framework of the building in the early stage, the core of curtain wall design is still to respect the original design scheme. Of course, under the premise that Party A requires substantial adjustment, curtain wall designers can properly optimize the building shape according to their own artistic cultivation and understanding of curtain wall structure.

Transfer from network