When designing some functional occasions, such as gymnasium, recording studio, library and other projects, is there any material that can meet the requirements of high sound absorption level, class a fire prevention and rich colors?

yes , we have! Ultra microporous sound-absorbing aluminum plate.

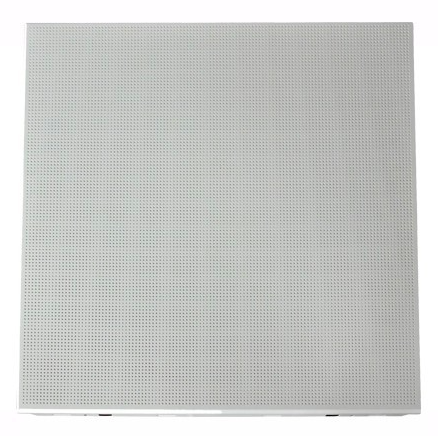

01·What is ultra microporous sound-absorbing aluminum plate

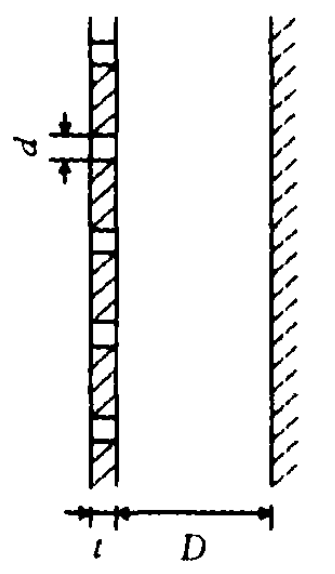

。The aperture of ultra microporous sound-absorbing aluminum plate is only half of that of hair. Ultra small aperture up to 0.04 × 0.4mm。 The sound absorption effect is more than 30% higher than that of traditional perforated aluminum plate. The surface can be sprayed with polyester powder or customized in any color through PVC film.

Transparent, breathable, but impermeable, with good anti permeability effect. The punching rate is less than 1%. It is a resonant sound absorption structure composed of thin plate and cavity behind the plate.

The use of composite materials on the back can complement the short and take the long, so that it has a very wide sound absorption frequency band, which belongs to the characteristics of full frequency absorption. It is widely used in airport waiting rooms, subway public spaces, high-speed railway waiting rooms, power stations, gymnasiums, hospitals and other commercial spaces.

02·Material characteristics of ultra microporous sound-absorbing aluminum plate

Compared with wooden sound-absorbing board, ultra microporous aluminum honeycomb metal sound-absorbing board has the advantages of moisture-proof, insect resistance, corrosion resistance, mildew resistance, no deformation, easy cleaning and convenient installation.

Advantages of microporous sound-absorbing aluminum gusset plate

1. The biggest feature of punched aluminum plate is that it can be combined with numerical control technology to fully realize the personalized and small batch home decoration needs;

2.Punching aluminum plate products have large plate width and good flatness after punching by machine tool operation;

3.Punching aluminum plate has high strength and light weight per unit area;

4.The perforated aluminum plate has good sound absorption and silencing effect, moisture-proof and mildew proof;

5.Punching aluminum plate is also easy to install and easy to construct. Each plate can be disassembled and replaced separately;

6.Punching aluminum plate can be customized according to customers' needs in terms of size, shape, surface treatment and color to meet customers' personalized needs;

Disadvantages of microporous sound-absorbing aluminum gusset plate

1. Compared with other materials, the installation process of microporous sound-absorbing aluminum gusset plate has higher requirements. If the joint is not handled well, it will affect the flatness of the whole ceiling.

2. The microporous sound-absorbing aluminum gusset plate needs to be marked with keel. Now there are mainly two kinds of wooden keel and light steel keel. If the wooden keel is selected, it is easy to be affected by moisture, which will affect the firmness and beauty of the ceiling.

3. As microporous sound-absorbing aluminum gusset plate is a popular ceiling at present, many businesses focus on business opportunities, shoddy products and uneven product quality, which is difficult for consumers to distinguish.

4. The plate type of microporous sound-absorbing aluminum gusset plate is not as rich as that of plastic steel gusset plate.

03·Production process

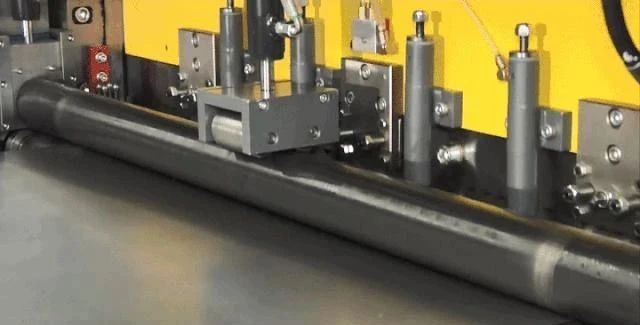

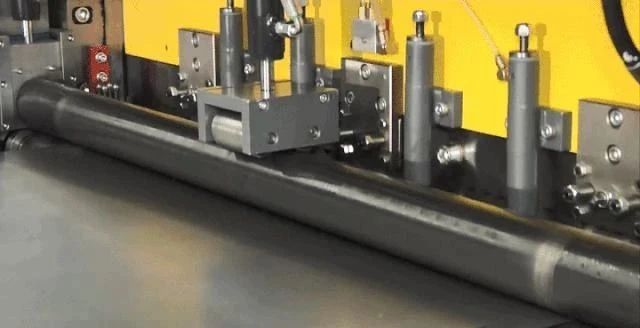

There are two commonly used perforation methods in modern tim

Numerical control punch

Numerical control punch is a common perforation method. Different metal plates are punched on the numerical control punch by cutting them into appropriate sizes.

▼

The stamping process can quickly perforate on the large surface area of metal screen and panel.

▼

Laser perforation

Laser perforation is the latest development of perforation technology. It is also an expensive and complex technology with higher accuracy and randomness.

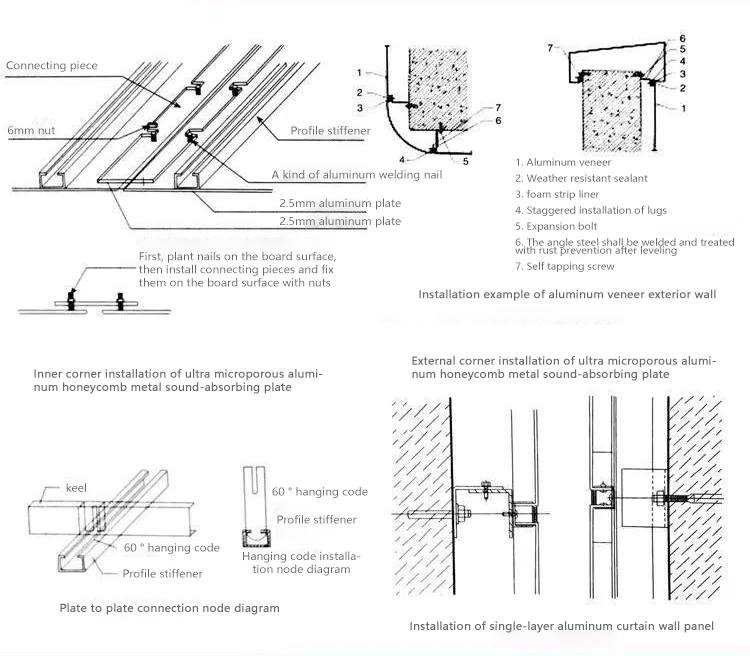

04· Construction technology

Snap the elevation control line - snap the boom point line - fix the boom - install the supporting keel - install the aluminum plate

a.Snap elevation control line

The elevation shall be determined according to the requirements of the drawing layout and the actual situation of the site, and the marks shall be popped on the surrounding walls and columns.

b.Snap boom point line

Determine the center position of the suspender lifting point according to the aluminum plate ceiling, and pop it up with a gray line. The spacing shall be less than 1200 and the distance from the edge shall be less than 300. The lifting point shall be checked in time after snapping. Do not omit the position line of additional suspenders at access openings and passageways.

c.Material selection and correction of suspender keel

The material selection and correction of ceiling supporting keel shall meet the design requirements.

d.Boom fixing

The suspender shall be made according to the suspender and elevation requirements in the figure, and the suspender shall be installed and fixed according to the position of the lifting point.

e.Installation of supporting keel

Use ∅ 6 full thread galvanized reinforcement to lift the keel to the snap line elevation, install and fix it, and pay attention to the arching of the middle part of the keel according to the design requirements.

f.Aluminum plate installation

On the basis of keel installation and leveling, hold the strip in place and clip it into installation from one direction in turn. First press one side of the aluminum plate into the keel clamp, and then press the other side into the corresponding clamp.

05·Material application

New comprehensive gymnasium in Fudan Jiangwan Campus

▼

Chinese University of Hong Kong (Shenzhen) library

▼

Guangzhou rongchuang Grand Theater

▼

Beijing Science and Technology Sports Center

▼

The same metal plate, different processing. In the hands of designers, they can be used in a variety of ways, injecting fresh vitality into the city we live in.

Turn from new micro design