Reading Guide:

When it comes to fluorocarbon coatings in the metal composite decoration materials industry, the first reaction is PVDF fluorocarbon resin coatings. As the most widely used and mature coatings in the industry, PVDF fluorocarbon coatings have excellent weather resistance and other indicators. However, the substantial rise of PVDF resin since last year has led to tight supply and rising prices of PVDF fluorocarbon coatings. As another product of fluorocarbon family, FEVE fluorocarbon coating began to appear in everyone's vision. Here I'll take you to know FEVE fluorocarbon coating again.

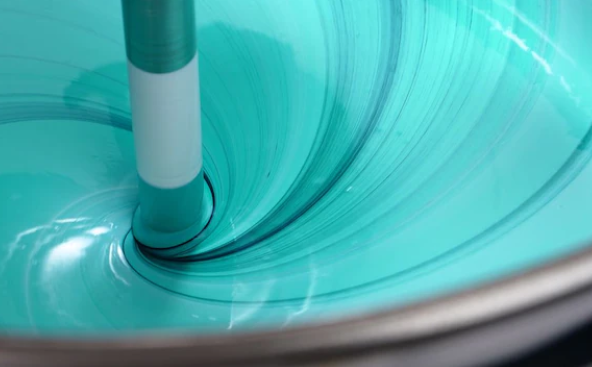

Figure / the demand for PVDF for lithium batteries of new energy vehicles is blowout, resulting in a serious shortage of PVDF resin supply

Maybe we all have questions at the beginning. PVDF and FEVE are called fluorocarbon coatings. What is fluorocarbon? The first "fluorocarbon coating" was born in 1938. The polytetrafluoroethylene resin synthesized by DuPont company of the United States has excellent weather resistance, heat resistance, chemical resistance and non stick performance; In 1946, DuPont commercialized polytetrafluoroethylene and developed the first fluorine-containing coating product Teflon, which needs to be baked at 420 ℃ to form a film. Teflon is mainly used for coating in non stick pot, lining of polymerization reactor, etc.

Figure / Teflon non stick coating

n 1965, pennwalt and ELF altochem successfully developed kynar500 polyvinylidene fluoride (PVDF) coating. Its quality standard is the famous aama2605 high performance coating standard. It is widely used in the field of building aluminum panel curtain wall. It has excellent aging resistance, chemical resistance and other properties, but it cannot be cured at room temperature. It must be baked at 240 ℃ to form a film. After years of development, PVDF fluorocarbon coating has become the most widely used and mature coating system in the industry.

Figure / PVDF fluorocarbon resin coating

n 1982, Asahi Nippon Co., Ltd. successfully developed lumiflon polytetrafluoroethylene copolymer resin (FEVE) room temperature curing fluorocarbon coating. The coating has high gloss and transparency, can be dissolved in conventional organic solvents, and can be crosslinked and cured at room temperature. The fluorocarbon coating is applied to PVC profiles, plastic steel profiles, FRP, steel structures and other materials, expanding the application field. Because FEVE fluorocarbon coating can be cured at room temperature and high temperature, it can not be restricted by construction conditions. In the previous 20 years, FEVE fluorocarbon coating has been widely used in outdoor wall, heavy corrosion protection of steel structure and other fields, with good application effect. However, it has not been widely used in the metal decoration material industry because of its relatively high price.

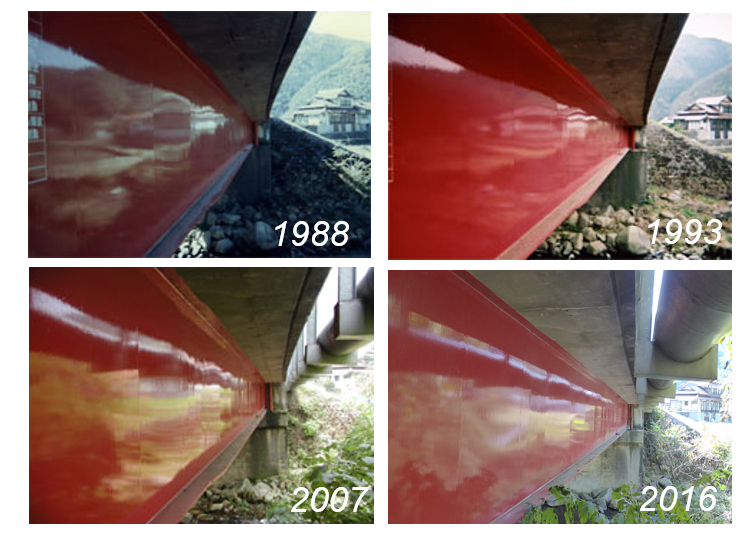

Application of FEVE coating in channel bridge

Figure / thirty year application case of FEVE coating - Hiroshima changpan Bridge

Since 2021, with the demand for PVDF resin for lithium battery blowout, the price of 142b resin, the upstream raw material of PVDF, has soared, resulting in a sharp rise in the price of PVDF fluorocarbon coating and a serious shortage of supply. In the current market, the comprehensive cost of FEVE fluorocarbon coating has a certain price advantage compared with PVDF fluorocarbon coating, which also provides an opportunity for the application of FEVE fluorocarbon coating.

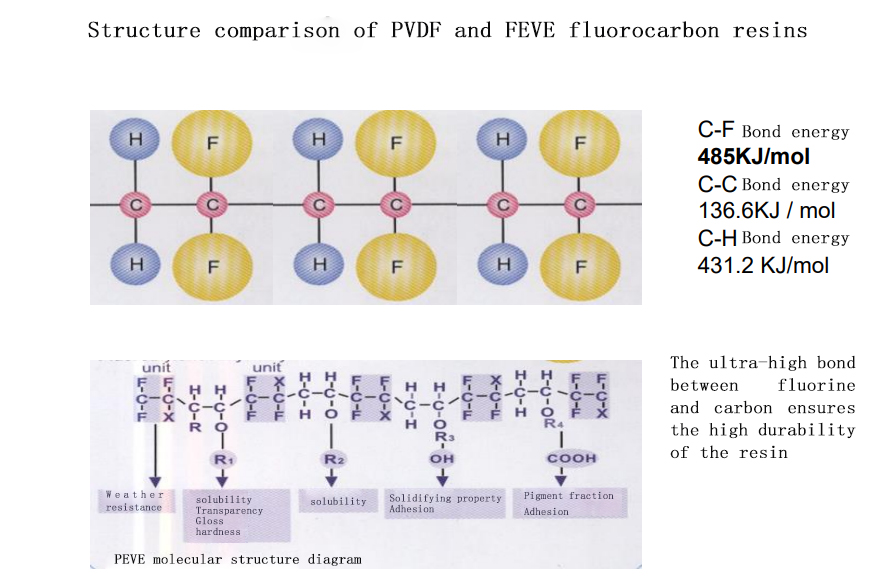

FEVE fluorocarbon resin is a copolymer formed by fluorine monomer and vinyl ether or vinyl ester monomer. According to different comonomers, FEVE fluorocarbon coatings can be divided into different types: according to the type of fluoromonomers, FEVE fluorocarbon coatings can be divided into two types: chlorotrifluoroethylene and tetrafluoroethylene; According to the type of comonomer, it can be divided into vinyl ether and vinyl ester. No matter what kind of coating, the factor determining the high durability of the resin is the ultra-high bond energy between fluorine and carbon elements.

Fig. / the ultra-high bond between C-F elements can ensure the stability of the resin

Compared with PVDF fluorocarbon coating, the main characteristics of FEVE fluorocarbon coating are as follows:

1. FEVE coating has a lower baking curing temperature of 216 ~ 224 ℃, which can save more energy consumption;

2. The solid content of the coating can reach more than 70%, and the VOC (≤ 420g / L) emission in the coating process is lower, which is more in line with the requirements of environmental protection;

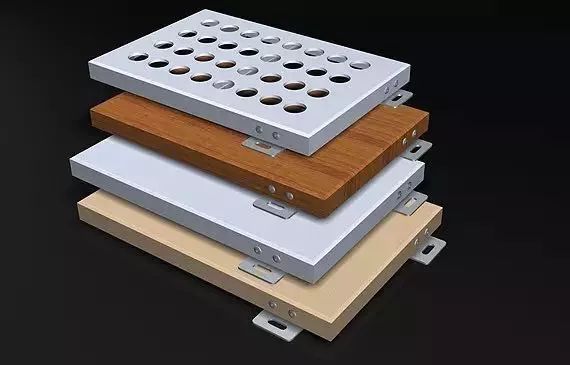

3. FEVE coating has high gloss and hardness, so it is more suitable for aluminum veneer products sprayed after bending;

From the above indicators, it can be seen that the application of FEVE coating meets the current national development requirements of low-carbon environmental protection, energy conservation and emission reduction. At present, Zhejiang has issued the comprehensive treatment plan for volatile organic compounds in the 14th five year plan of Zhejiang Province, which requires the substitution of low VOC coatings. It can be said that the use of more environmentally friendly coatings has become the general trend.

As we all know, the weather resistance of PVDF fluorocarbon coating has experienced the test of time in the metal decoration material industry. Although FEVE fluorocarbon coating also has its corresponding application cases, due to its relatively complex classification of trifluoro and tetrafluoro, ethers and esters, the weather resistance of different types has also troubled the application of downstream metal decoration material enterprises.

Therefore, the metal composite branch and China National Inspection and testing Holding Group Co., Ltd. plan to jointly carry out the weather resistance comparison test between FEVE coated aluminum plate products and PVDF fluorocarbon coated aluminum plate products. Through the durability system test under laboratory acceleration and natural conditions, the branch will comprehensively compare the durability characteristics of FEVE coated aluminum plate products with environmental friendly PVDF fluorocarbon coated aluminum plate. The specific comparison test scheme will be announced soon, Fluorocarbon resin enterprises, coating enterprises and plate manufacturers are also welcome to actively participate.

Transferred from metal composites branch