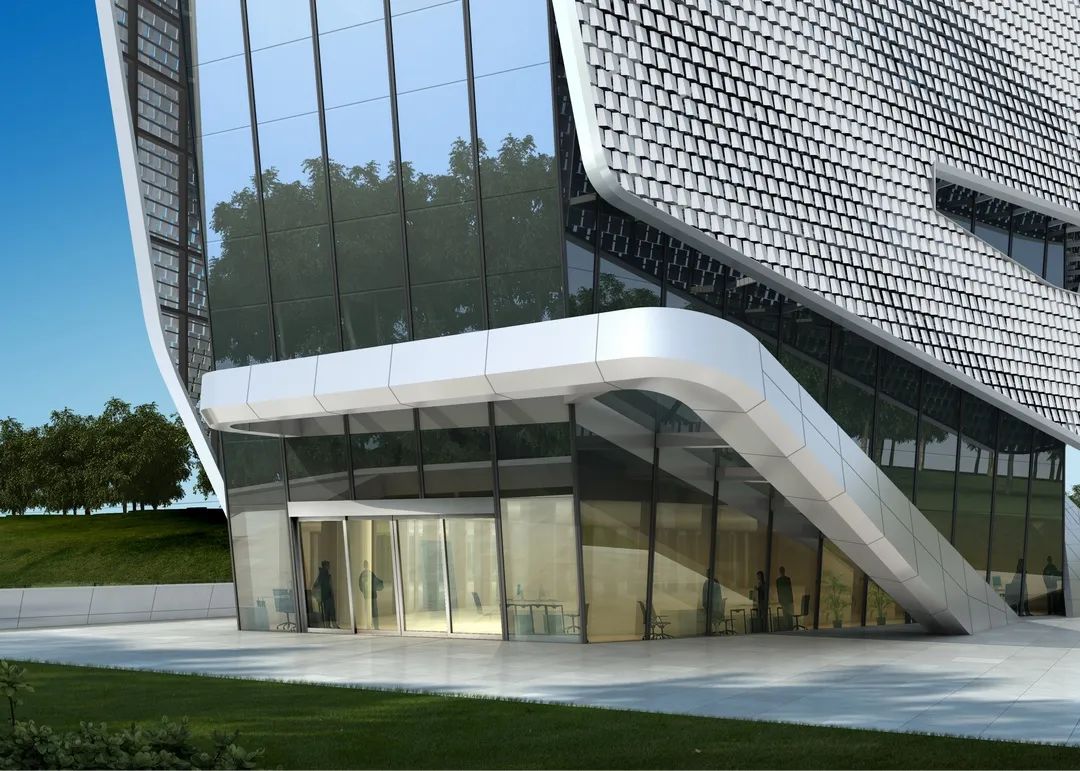

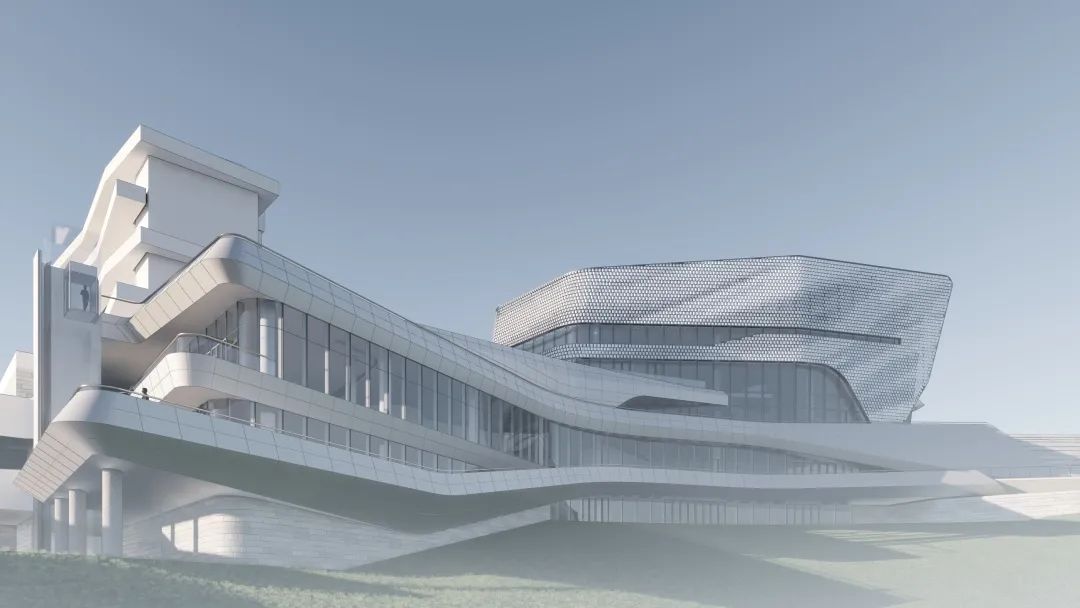

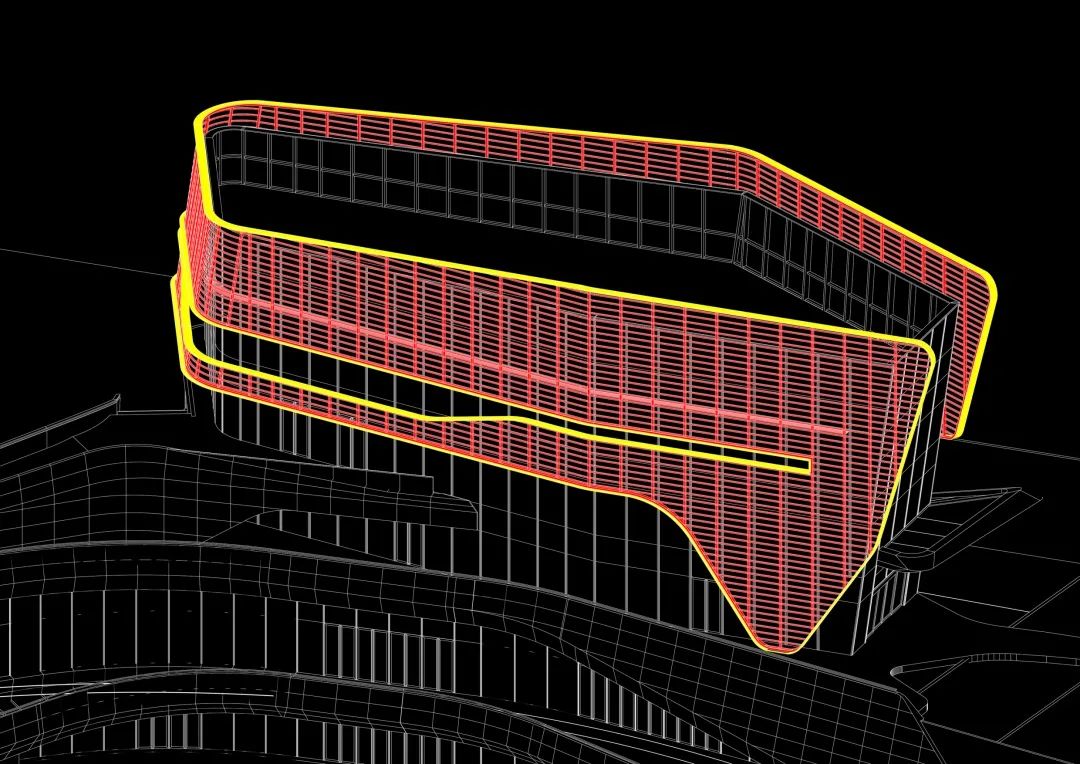

The urban reception hall of Chongqing Luyue river city is located on the top of the river valley. Aluminum flakes are used to create a light posture and show the sense of transparency and cleanness of the building itself. How is the special-shaped scale curtain wall made in the project?

01.

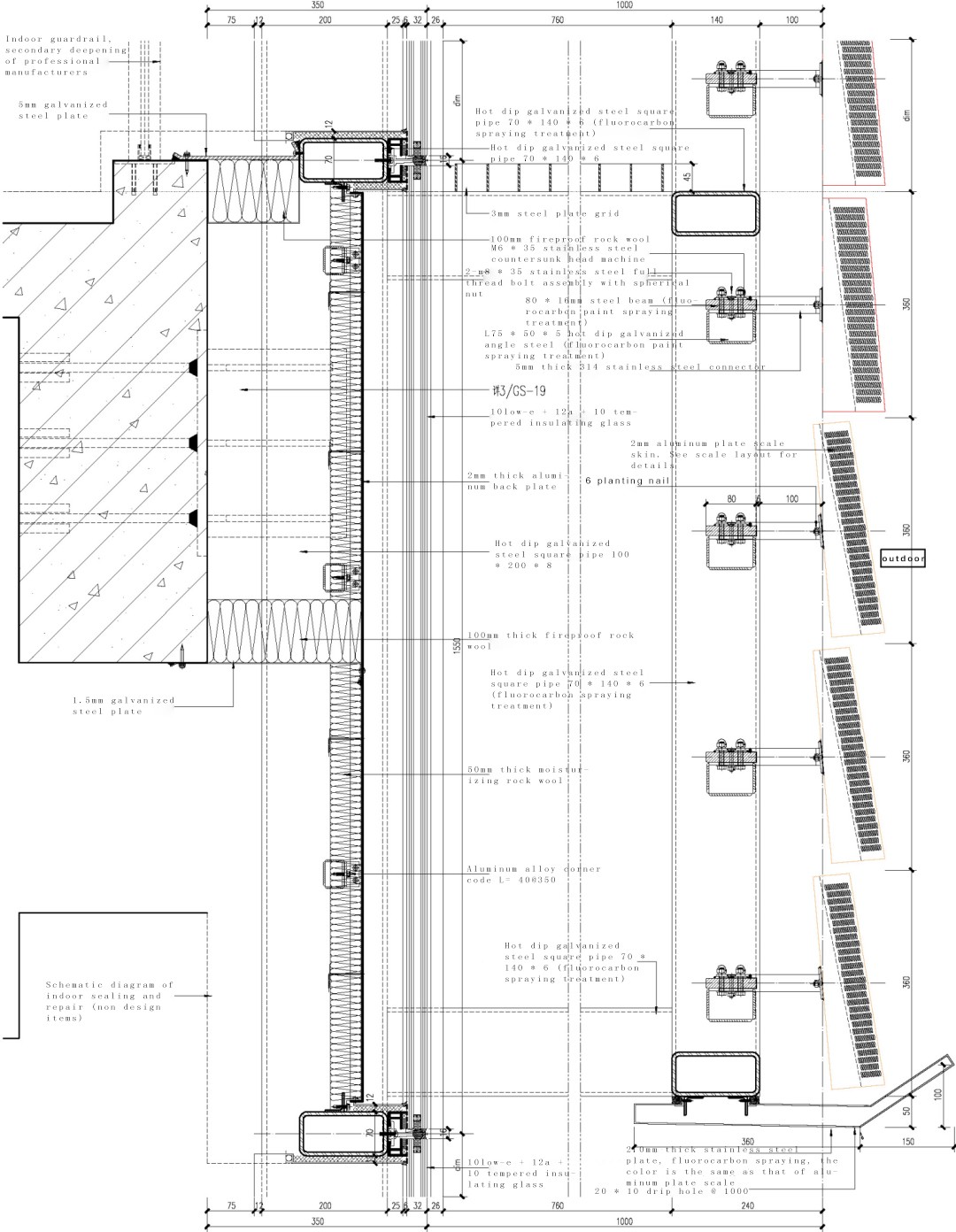

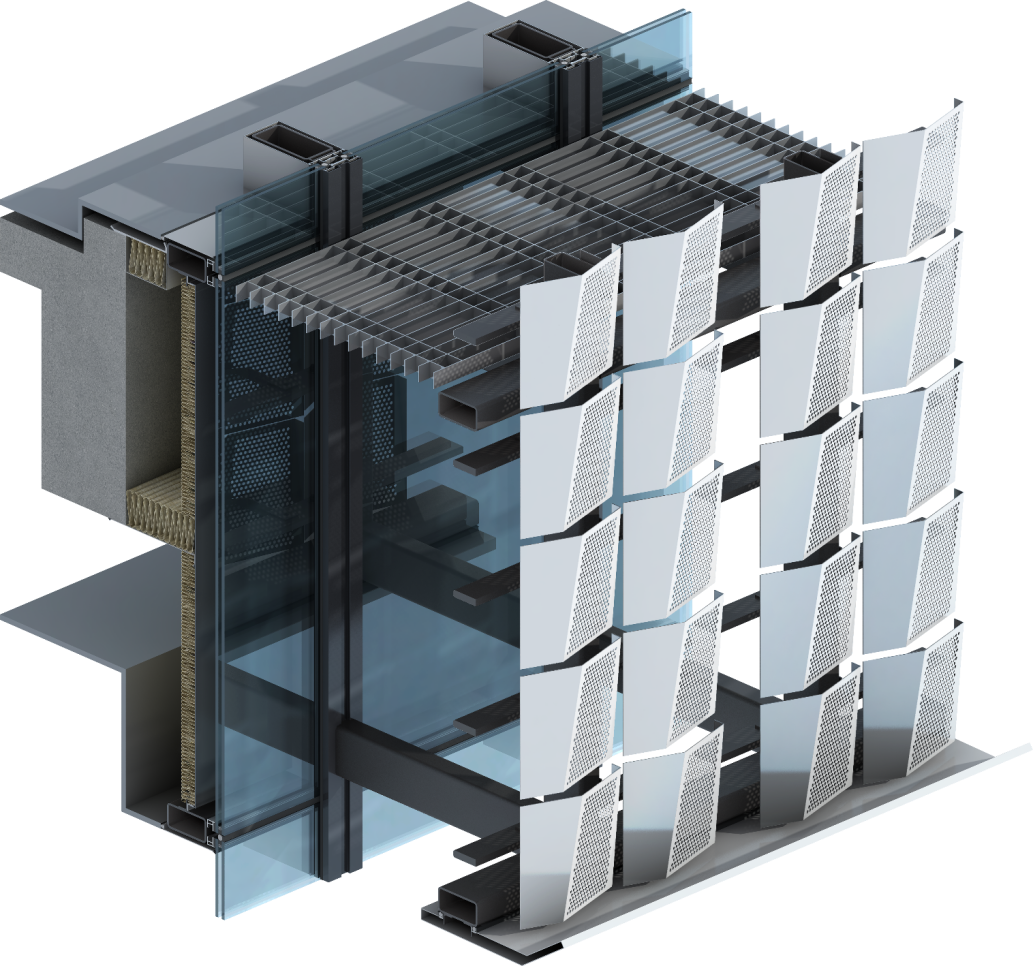

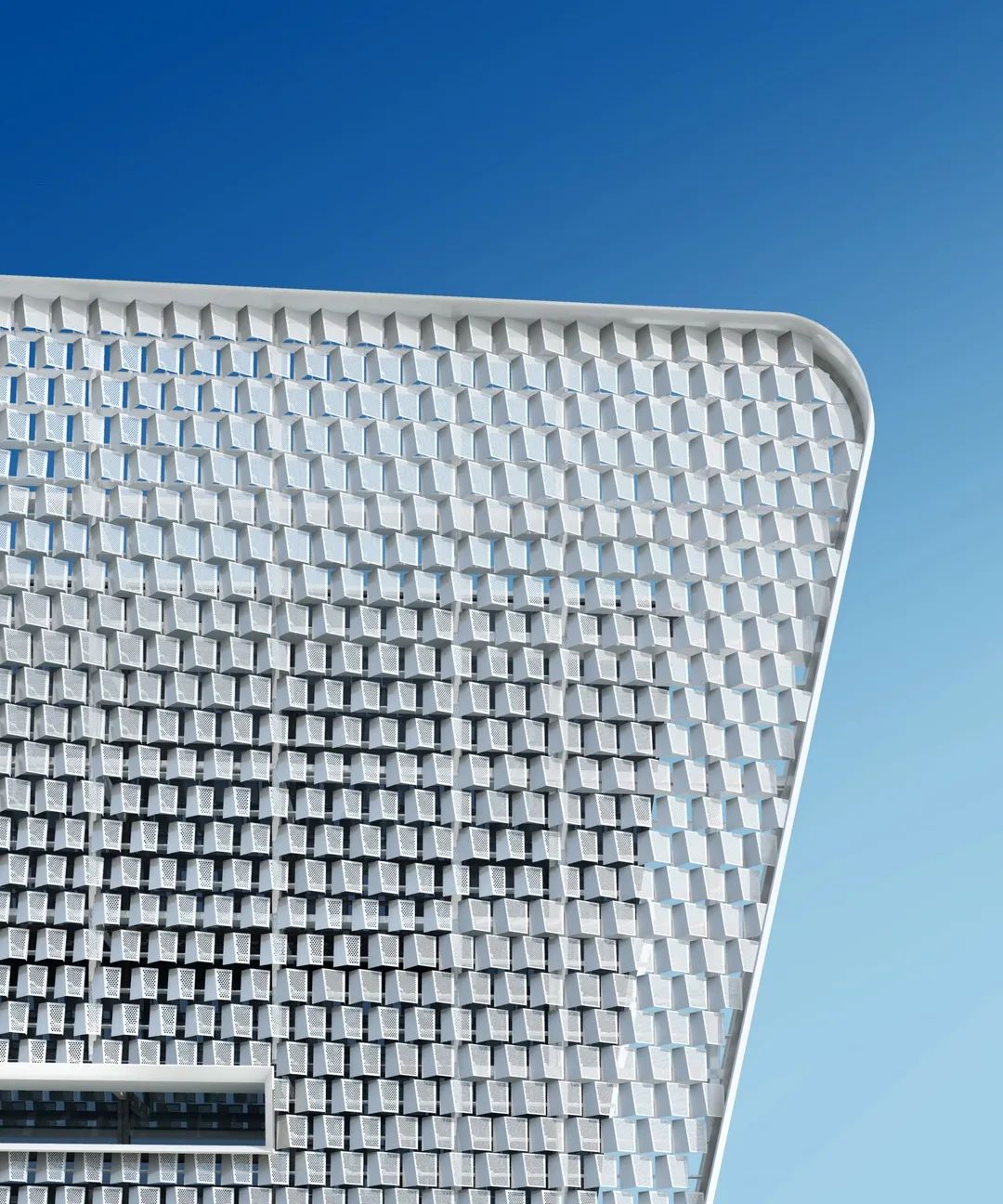

External facade of special-shaped flake aluminum veneer

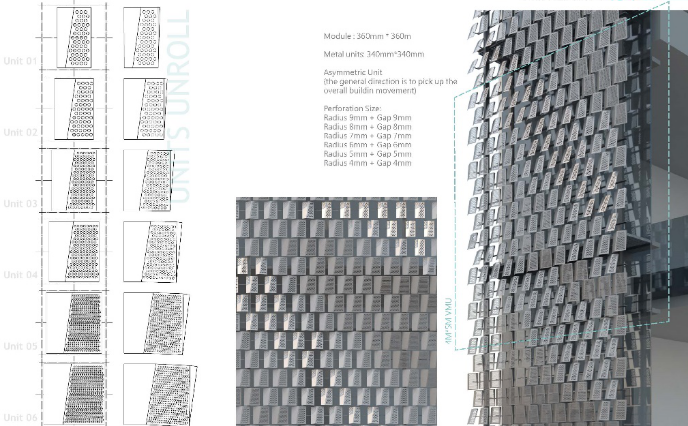

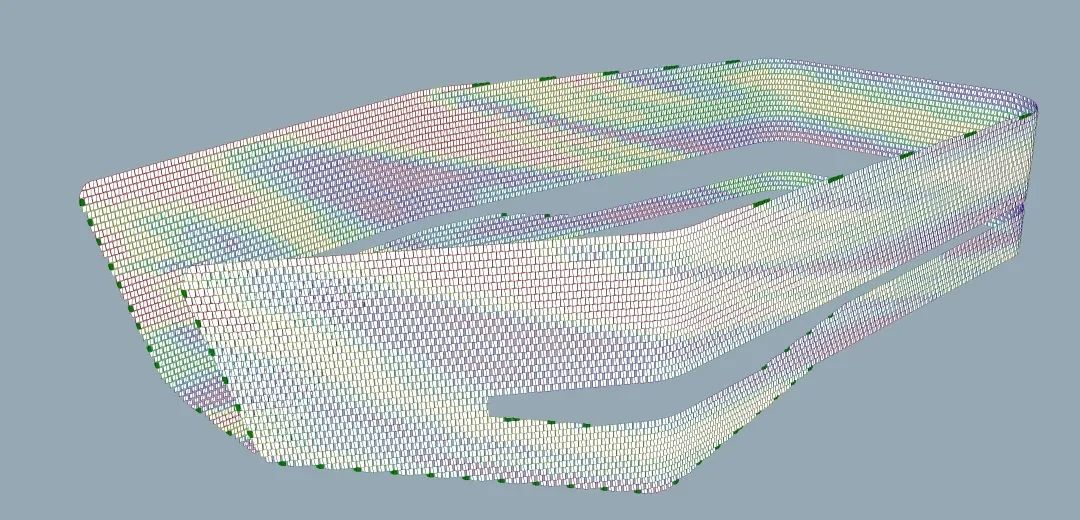

How do static aluminum veneer scales show dynamic effects? Thanks to the geometric flake aluminum veneer combined with different angles.

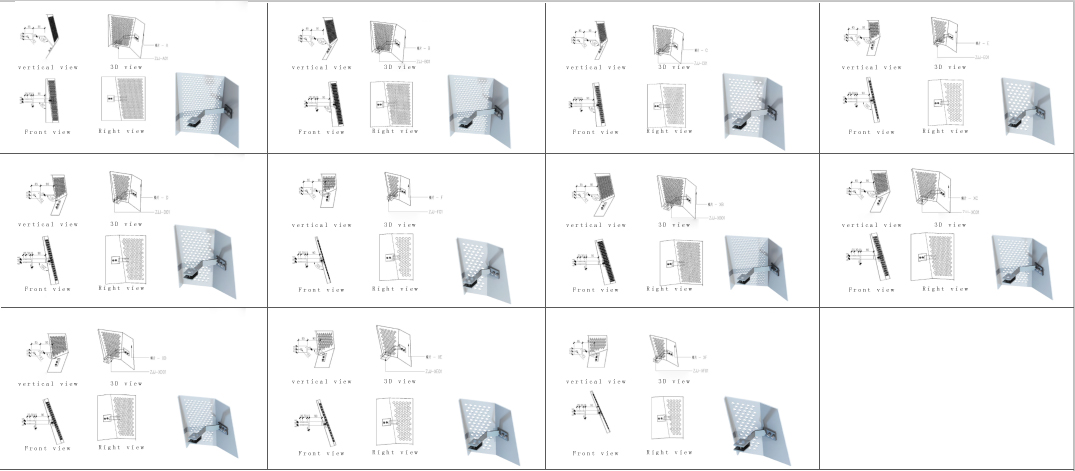

The curtain wall unit has conducted many physical proofing tests, and finally selected 2mm thick flake aluminum veneer, and customized stainless steel connectors to reduce the construction difficulty as much as possible. While meeting the safety performance requirements, ensure that the height of the finished surface is flat and consistent with the design scheme.

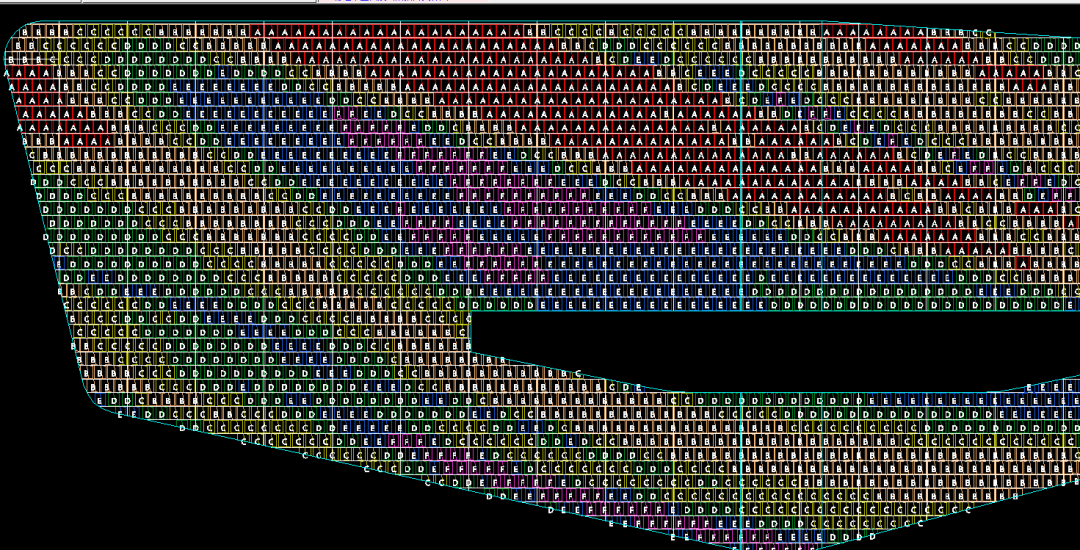

Six kinds of aluminum veneer scales with different specifications and angles are combined with 11 kinds of 304 stainless steel connectors with different angles.

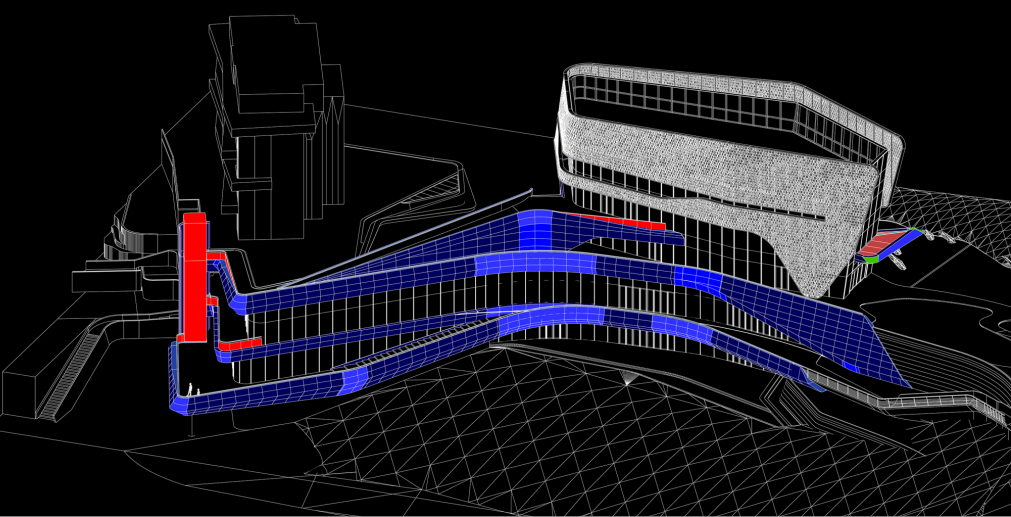

BIM Technology is involved in giving each group of scales a unique number and a specific installation point. In the later construction process, the workers fix the specified castings to the specified points according to the installation layout to ensure that the final effect is within the controllable range.

In order to make the change of aluminum alloy scales in the sun more layered, fluorocarbon paint process is selected. The flake surfaces of 8527 aluminum veneers were treated by three coating and two baking processes.

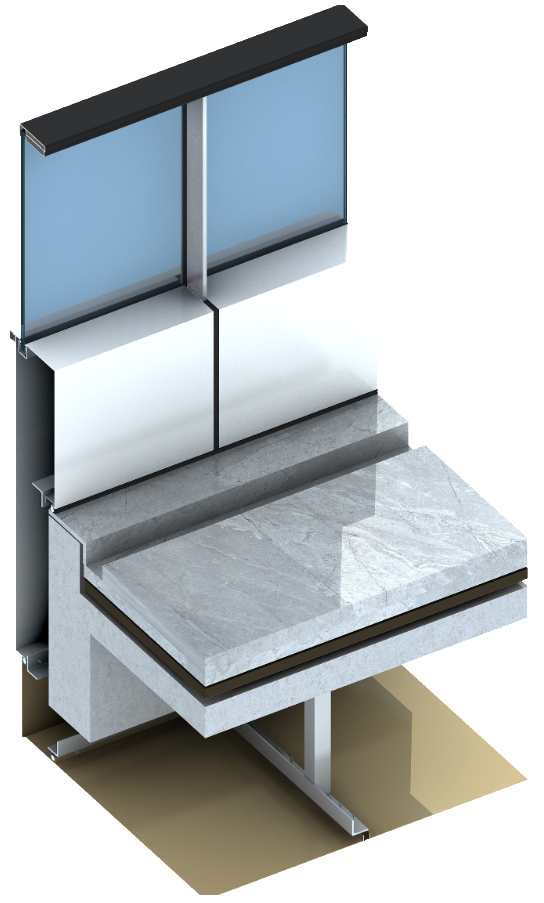

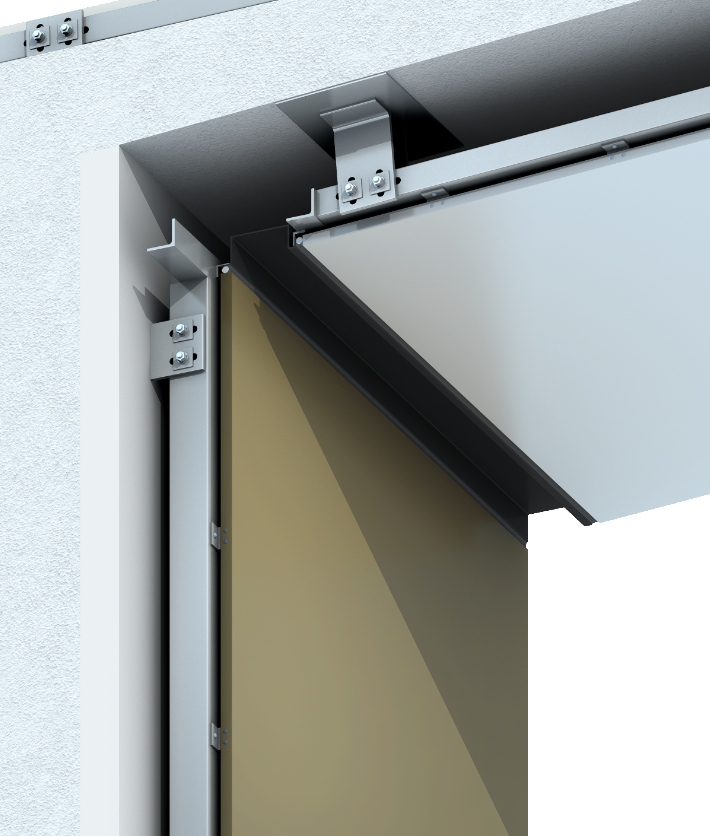

16mm thick steel plate is used as the steel beam to minimize the impact of the steel beam with stainless steel connectors on the indoor permeability.

The glass curtain wall keel shoulders the load-bearing responsibility of the outer scale curtain wall. Considering the interior decoration effect, designers used the steel structure system to design the keel, reduced its size to 270mm * 120mm, and changed the traditional bolt connection mode to welding mode.

And 1.5mm stainless steel is used to reseal the curtain wall keel and change the color of fluorocarbon paint, so as to further weaken its impact on the indoor effect.

02.

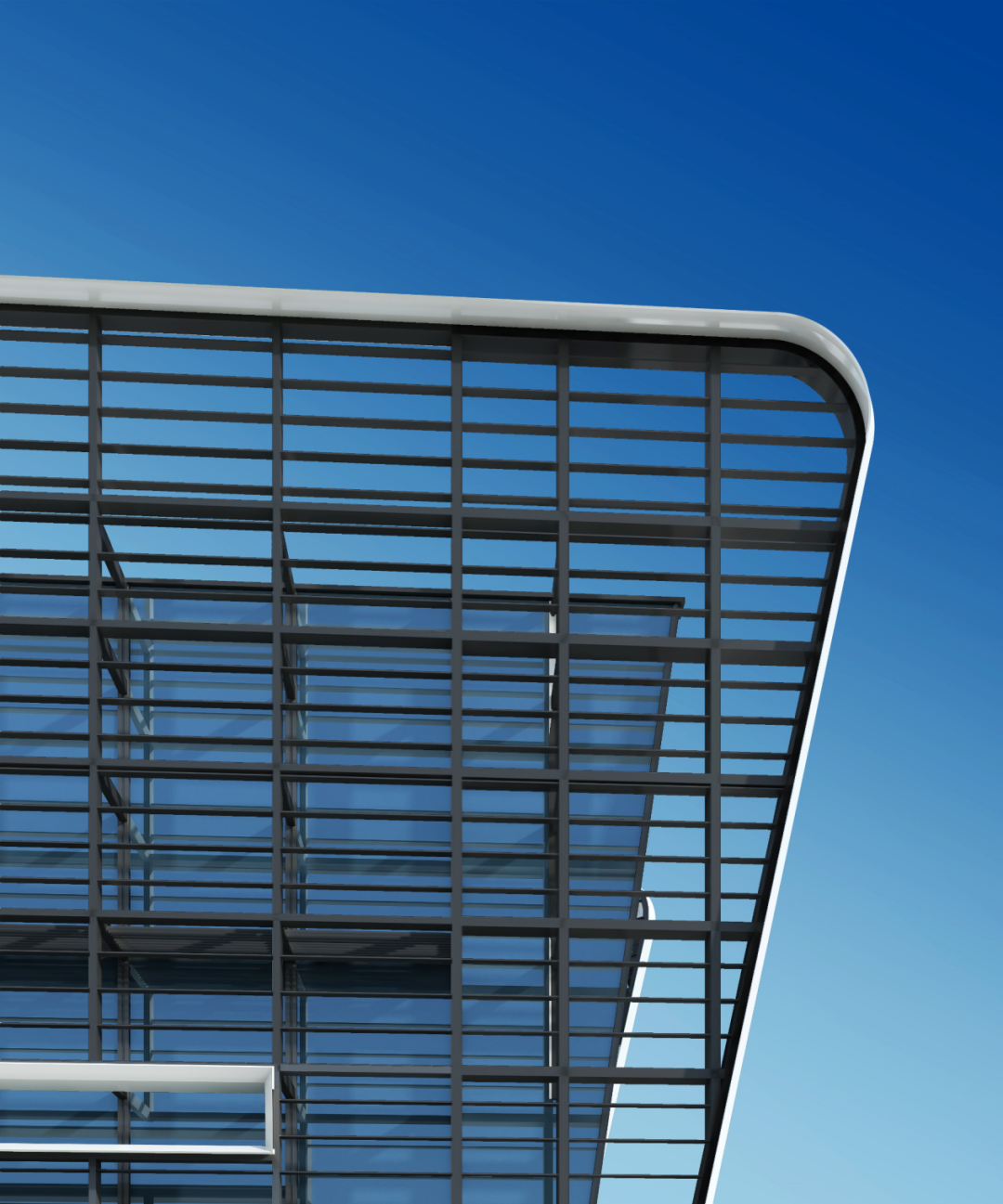

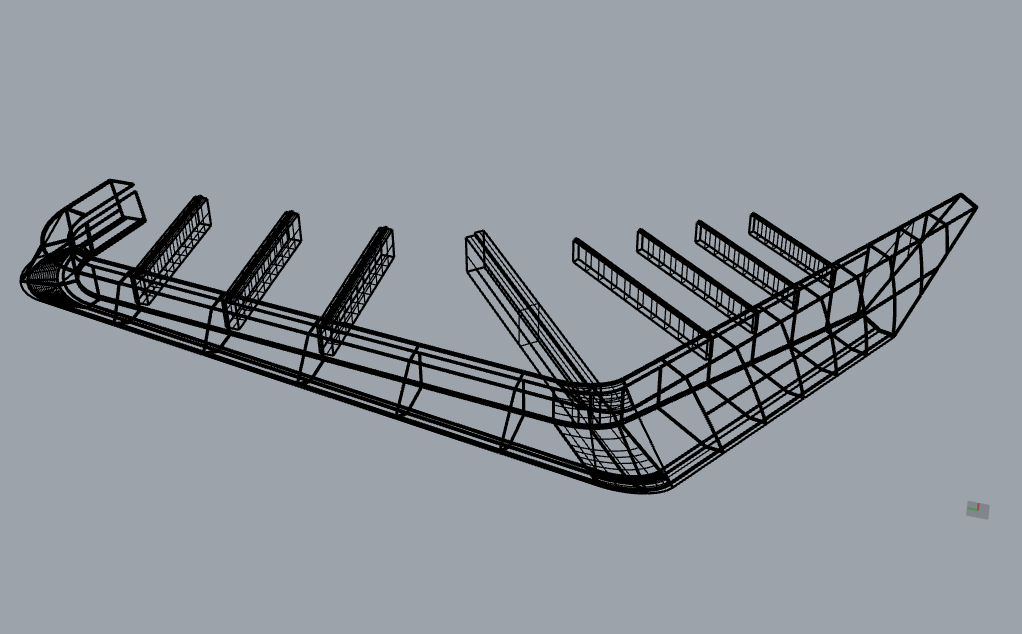

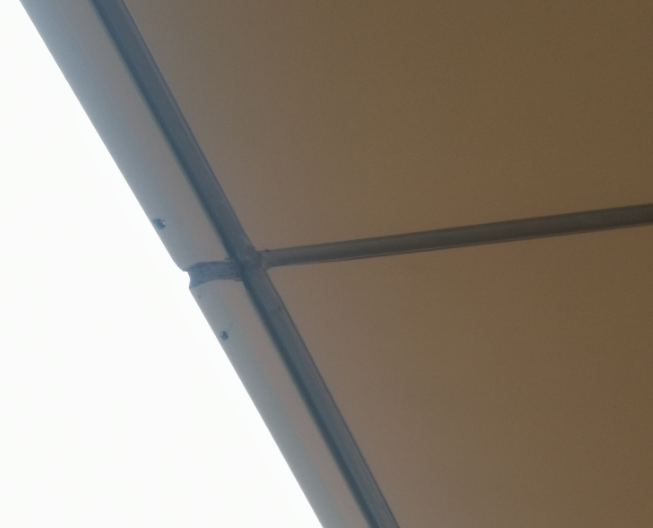

Special shaped plate of canopy

The canopy is made of 3mm sandblasted stainless steel, including 16 double curved plates and 28 single curved plates, and the special-shaped plates account for 1 / 3 of the total plates.

In order to prevent the canopy tie rod at the main entrance from damaging the neat effect of the facade, the designer proposed the design scheme of integrated treatment of the canopy steel structure with a cantilever of 6m and the keel of the glass curtain wall, so as to achieve the best effect of the scheme.

03.

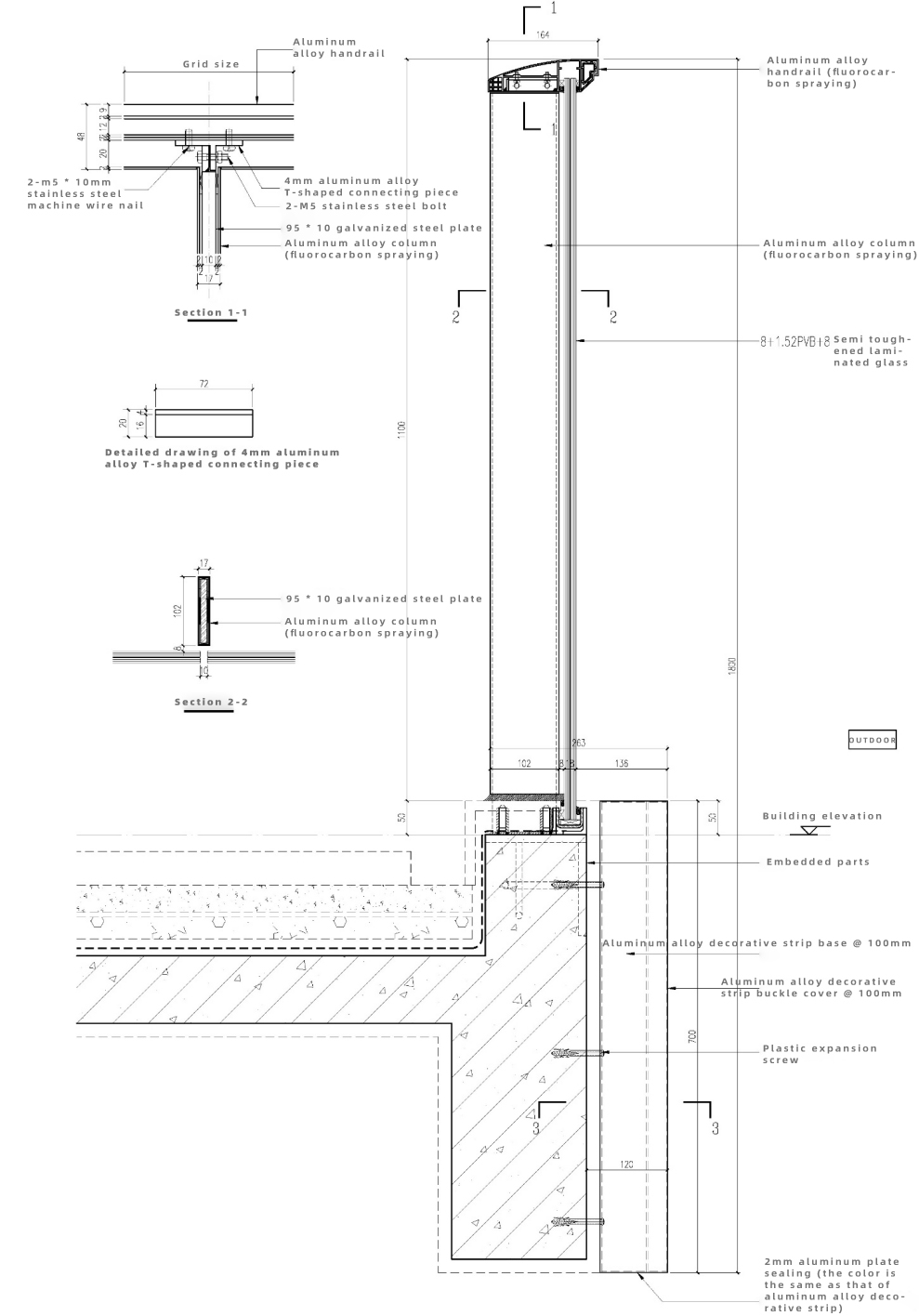

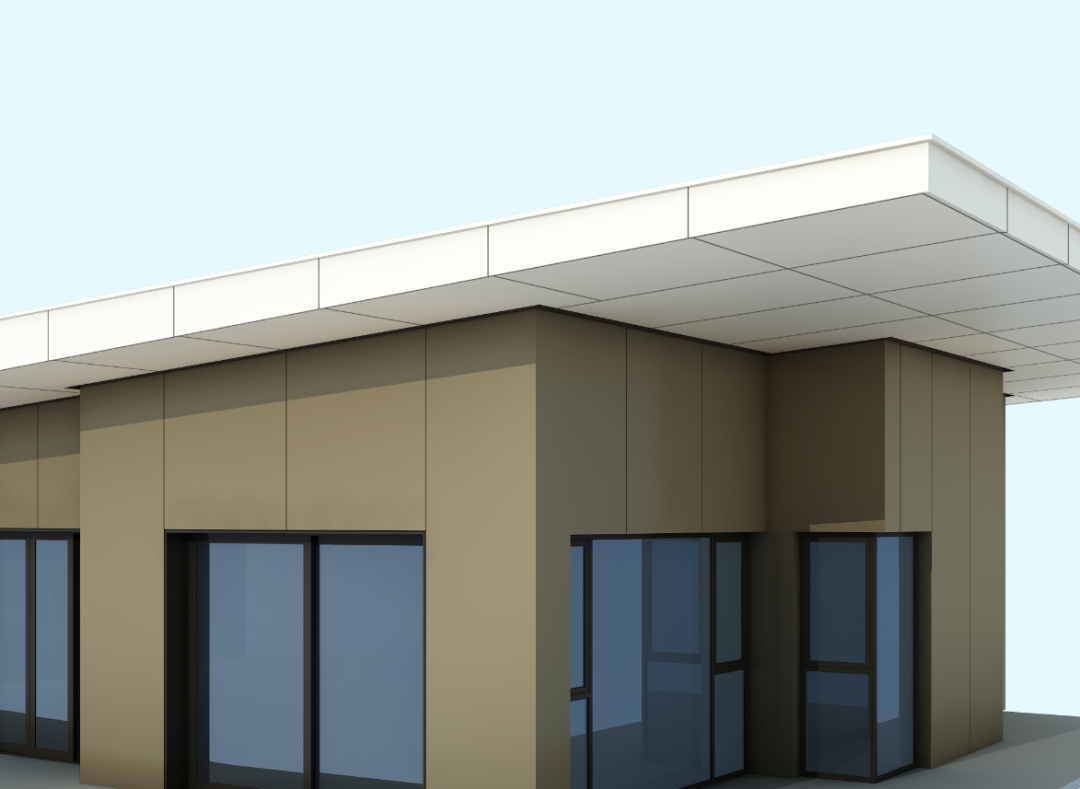

Aluminum plate facade

Designers abandoned the simple aluminum plate installation scheme of "broken line into arc" and demanded that the aluminum plate show the ultimate sense of ribbon. Among the 787 aluminum veneers, the number of special-shaped plates reaches 20% of the total.

Considering the problem of facade fouling caused by long-term sun exposure and wind blowing, the designer added a drip line design at the joint of aluminum plate to reduce the sagging of negative aluminum plate and greatly improve the stain resistance of facade. In the process of drip line design, the floodlight trough is cleverly set to meet the integration needs of floodlight and curtain wall.

04.

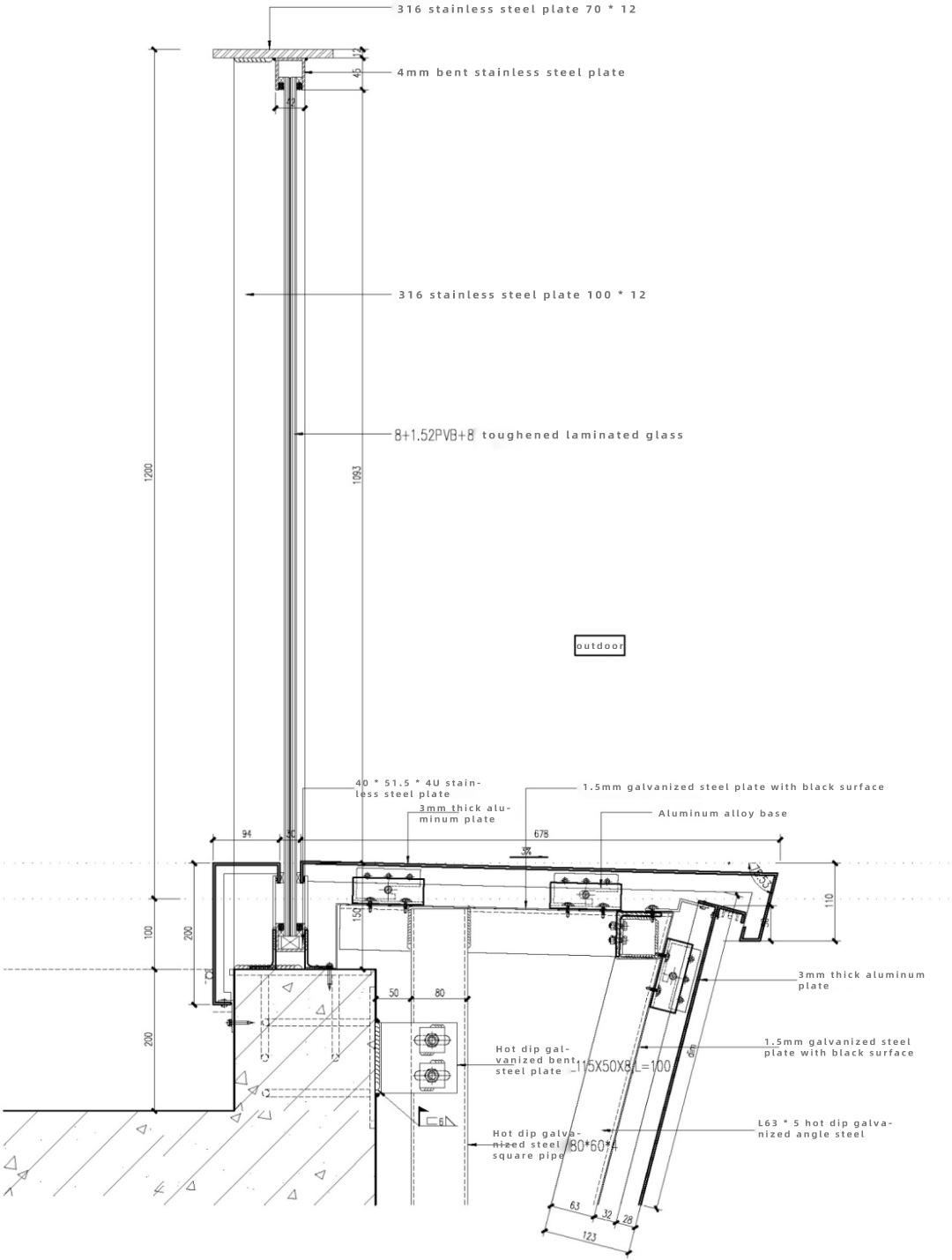

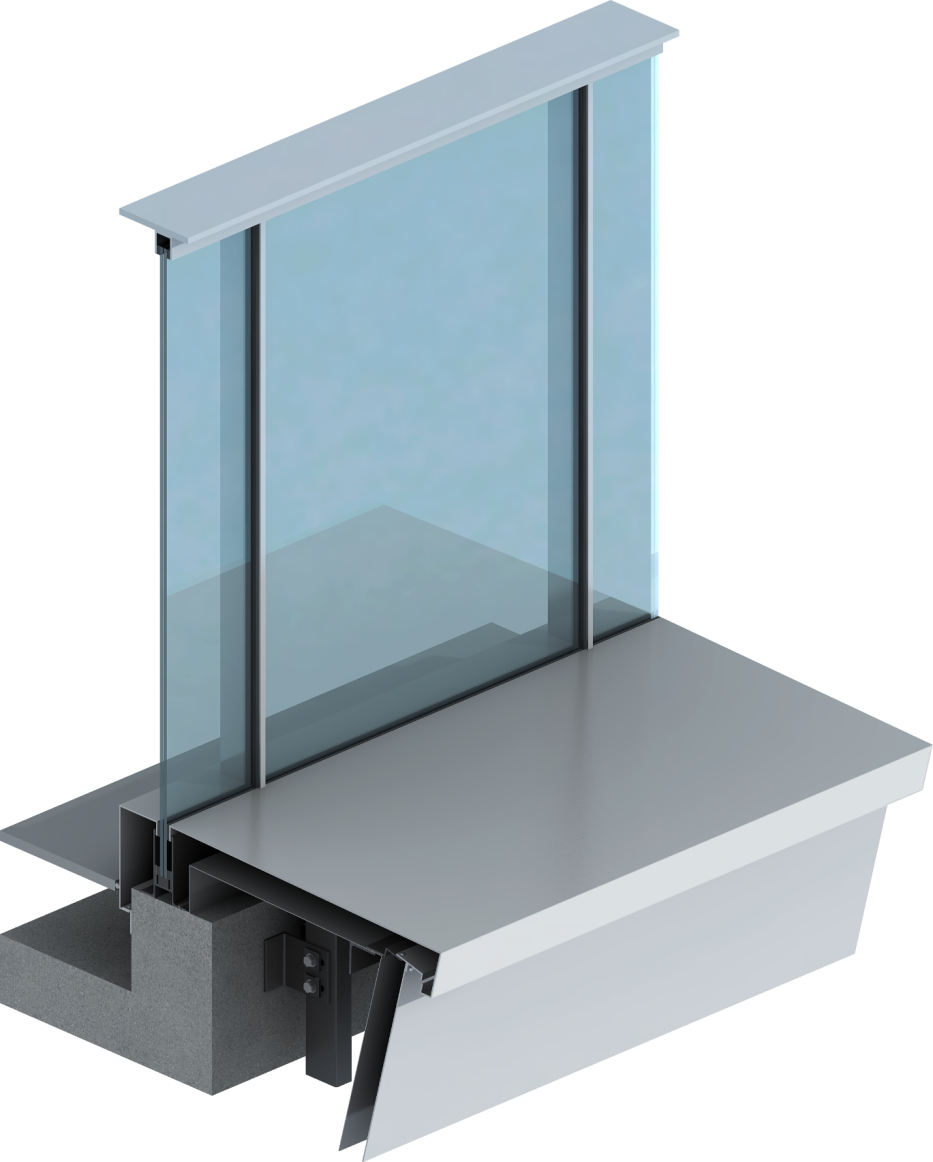

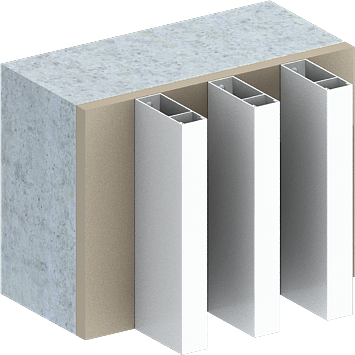

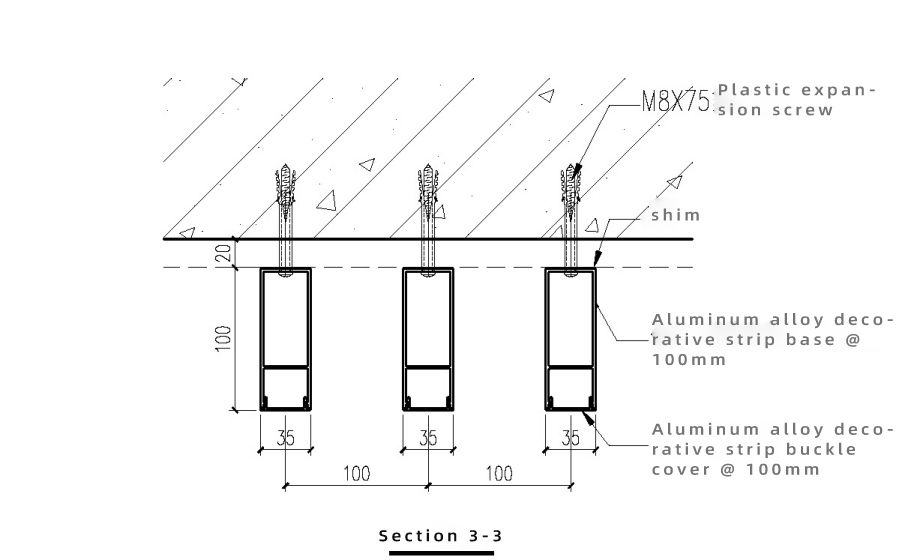

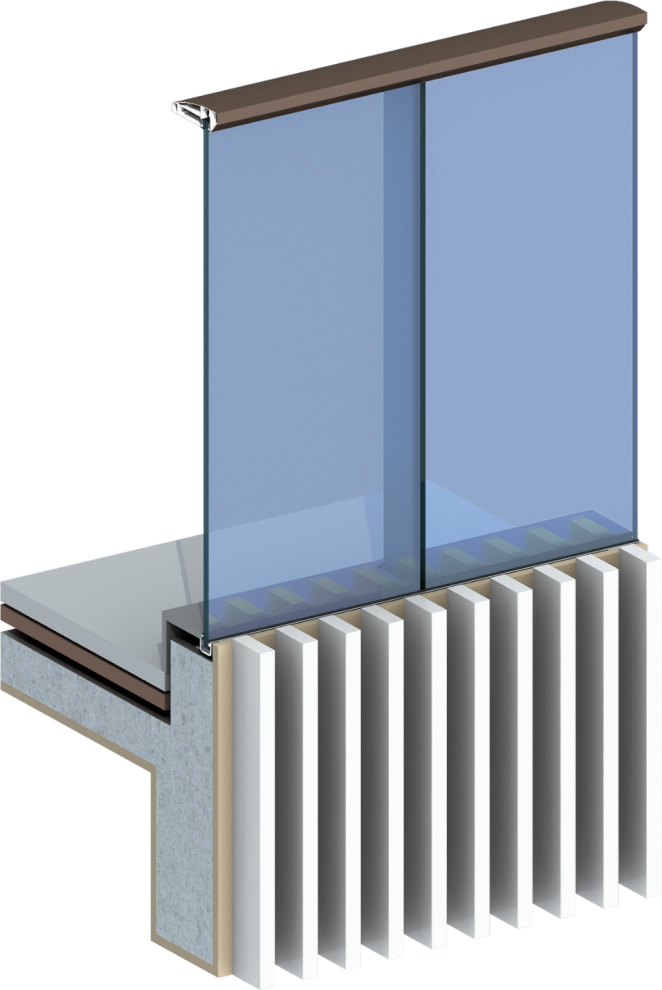

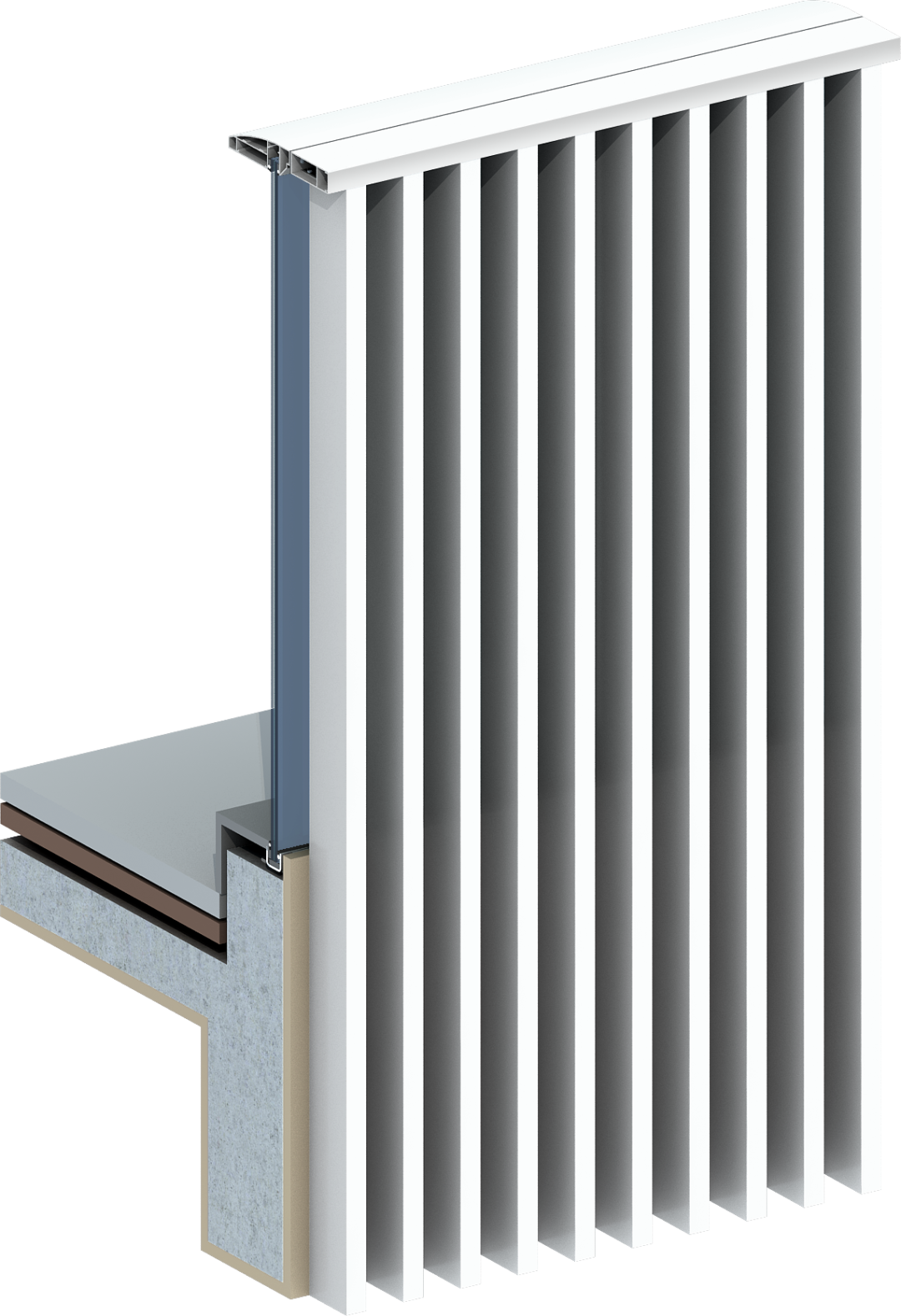

Villa terrace

There is a set of aluminum plate application scheme for single and double buildings, different floors and different locations. Similarly, the electrostatic spraying process of three coating and two baking fluorocarbon paint is used to help lock the shape and surface color of aluminum alloy profile and meet the weather resistance and visual requirements to the greatest extent.

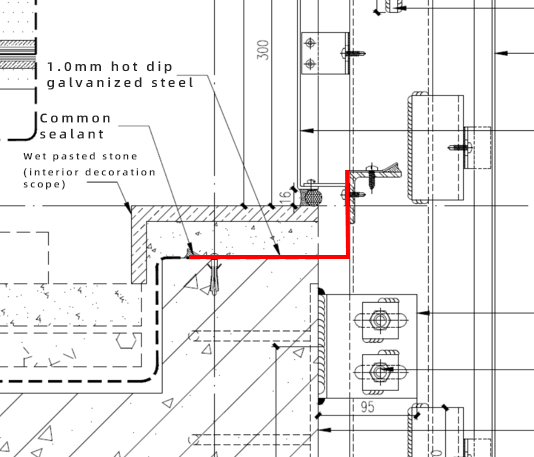

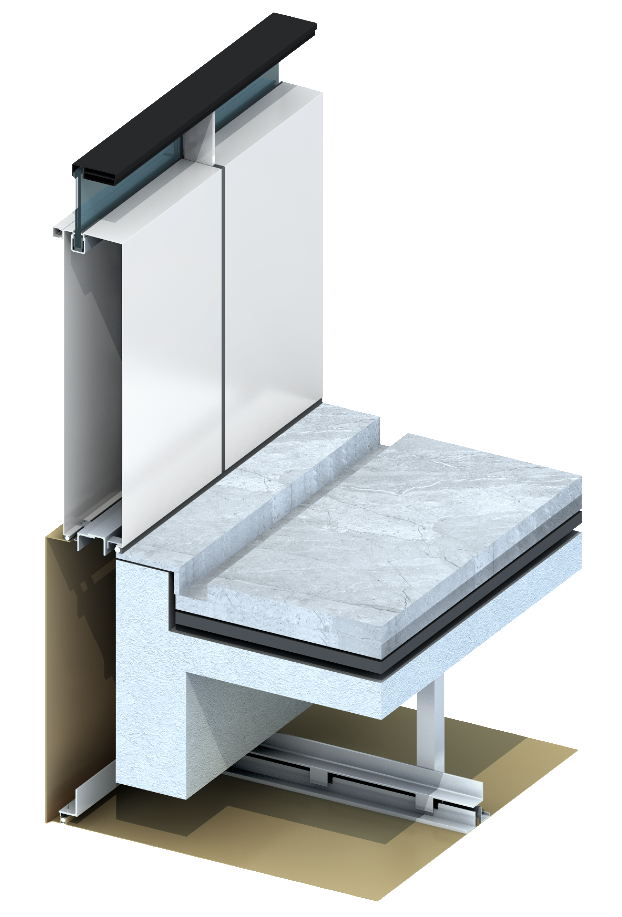

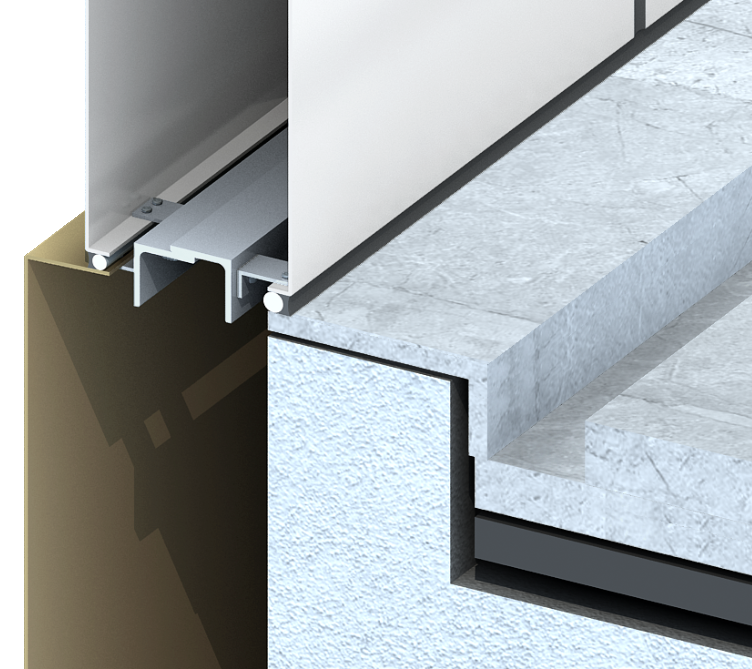

(Balcony nodes)

The aluminum plate ceiling drain hole is an 8 * 16mm oval drain hole with a distance of 50mm from the edge, which is convenient for the natural outflow of rainwater and prevents ponding in the aluminum plate.

Balcony breast board shall be installed outside the structural beam, and 1.0mm thick full-length iron sheet shall be set between the inverted sill and the keel for sealing to upgrade the waterproof effect.

Note: This article is transferred from the online editing and sorting of materials from: Zhejiang Zhongnan curtain wall design and Research Institute