01.

What is titanium zinc plate?

Titanium zinc plate, also known as titanium zinc alloy plate, zinc copper titanium alloy plate and titanium gold plate, is an alloy made of high-purity Z1 metal titanium and a small amount of metal titanium, metal copper and metal aluminum, which is rolled into sheet, strip, plate or roll building material plate.

Characteristics of titanium zinc plate

Excellent ductility

The plate has good elongation and tensile strength, good plasticity, and can be shaped in three-dimensional arc bending on site.

Super long service life

Natural corrosion resistance, service life up to 70-100.

Self cleaning

Because there is no coating on the surface of titanium zinc plate and no static electricity is generated, it does not absorb dust and dirt. After being washed by rain, it directly takes away the stains on the plate surface and forms self-cleaning characteristics.

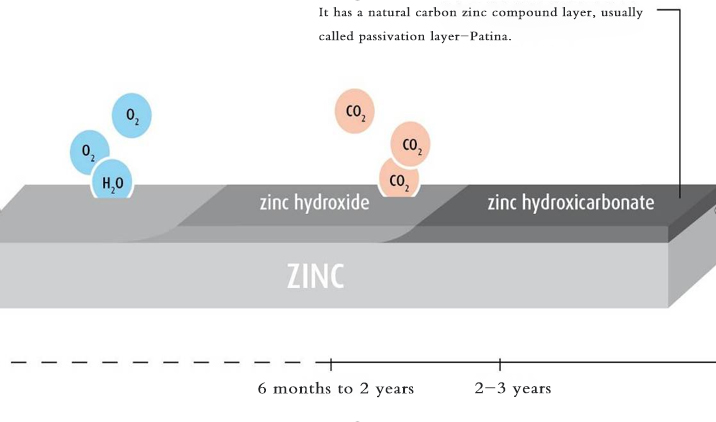

Self-healing

After the titanium zinc plate is scratched during transportation or installation, due to the oxidation of zinc, the zinc element will react with water, oxygen and carbon dioxide in the atmosphere again, and the oxide layer will be formed again at the scratched part, and the color will be infinitely close to the color of the surrounding plates, thus forming the characteristics of self-healing.

Expensive

Among many metal materials, the price of titanium zinc plate is relatively expensive, but due to its superior material properties, its cost performance is also in the range of medium and high.

Type of titanium zinc plate

Titanium zinc plate can usually be classified according to the material treatment process and the color of the plate.

a.The surface treatment process of titanium zinc plate is simple to classify

1.Pickling:

The surface of titanium zinc plate is treated with a diluted mixture of sulfuric acid and nitric acid to form an approximate natural passivation layer. A transparent organic film is then attached to the surface to protect the surface of the material during transportation and storage.

2.Phosphating:

The phosphating process is carried out by forming a slightly soluble phosphate layer on the surface of the panel. There are all necessary components, phosphate anions and metal cations in the phosphating tank. Depending on the pretreatment, light or deep surface colors can be produced.

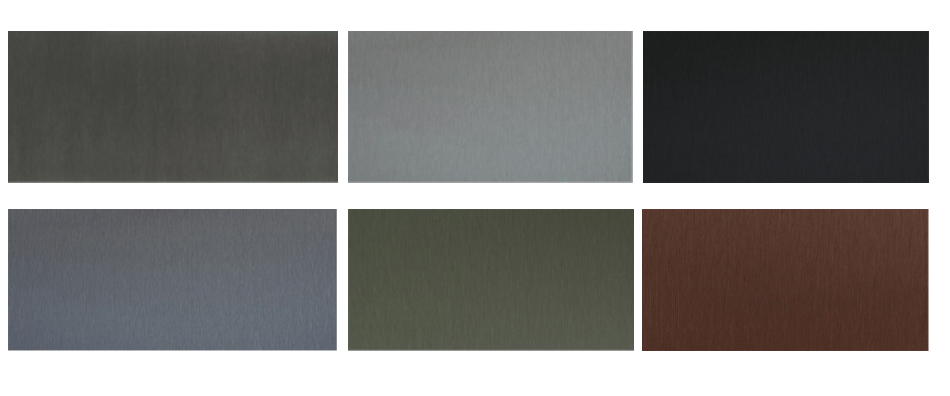

b.Classification according to different plate colors

According to the color of the plate, titanium zinc plate can be divided into primary color (NATURAL passivation) and pre passivation color.

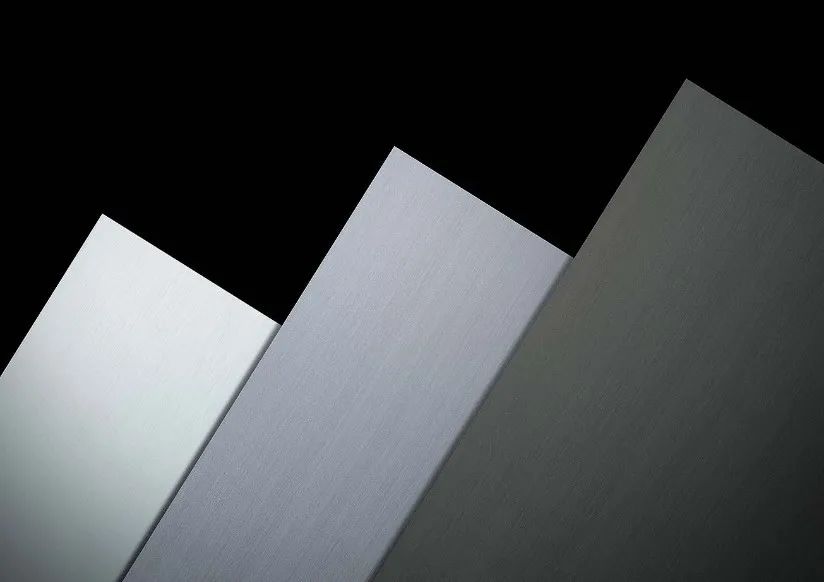

1.Primary color (NATURAL passivation):

After pickling, a blue gray or graphite gray alkaline zinc carbonate layer will be formed on the surface of the titanium zinc plate. Make it close to the oxidation state in the natural environment, and accelerate the oxidation through pretreatment, showing a color close to the natural oxidation effect.

▲Material schematic

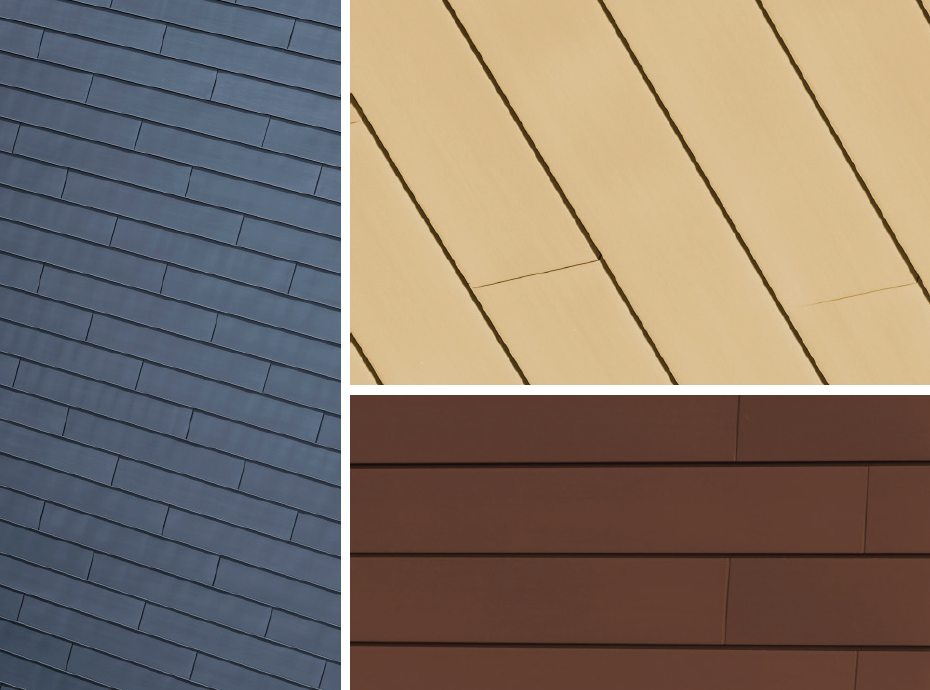

2. Pre passivation color

The surface is not painted, but formed by adding a small amount of mineral pigment to the passivation layer. The common colors are green, red, blue, brown and black. Especially with the change of light, it will show different colors, giving people a wonderful visual beauty.

▲Material schematic

02.

Installation process of titanium zinc plate

Titanium zinc plate is mainly used in roof system, curtain wall system, water falling system, interior decoration, roof decoration and so on. It is especially suitable for public buildings (especially landmark buildings), such as airports, convention and exhibition centers, cultural centers, stadiums, senior residences, senior office buildings, etc.

Source: RHEINZINK

The process of titanium zinc plate is similar to that of aluminum veneer. When it is used as roof and wall, its installation process is different.

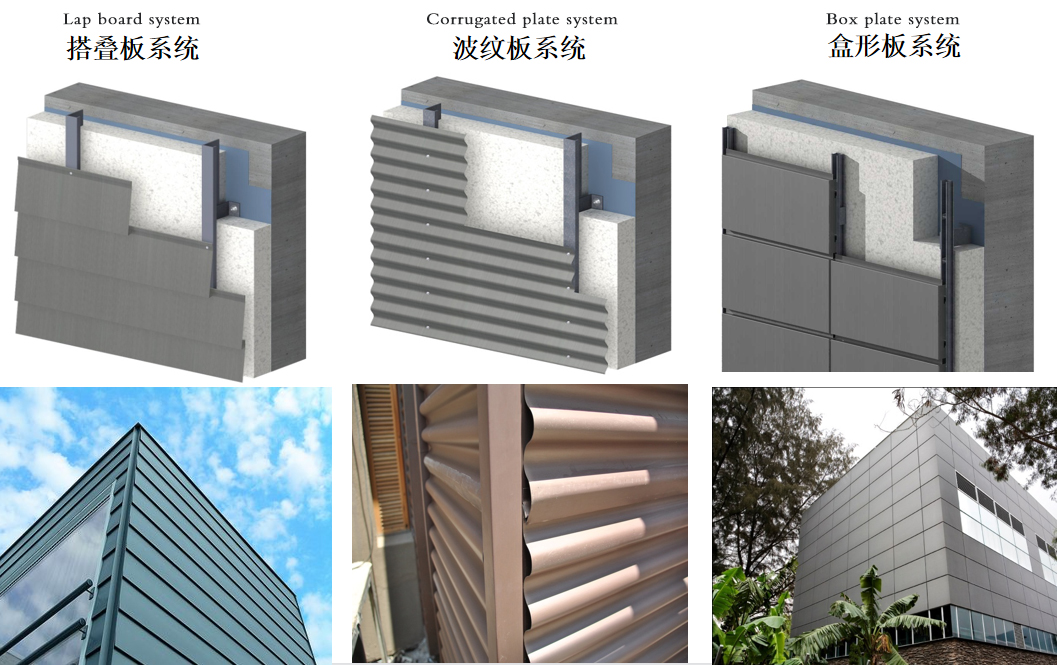

1.Titanium zinc plate wall system

The wall system can be divided into: lap board system, corrugated board system and box board system.

Source: Shanghai unilite architecture

PS:Matters needing attention

① During the construction of titanium zinc plate internal locking system, it can be horizontally, vertically and horizontally. Laid obliquely on a flat surface.

② The construction of wall system engineering is completed on the main structure of civil engineering, and embedded parts or post embedded parts need to be set.

③ The supporting frame of the internal shrinkage buckle system can be galvanized steel keel with a minimum thickness of 1.5mm or aluminum keel with a minimum thickness of 2mm;The keel width shall not be less than 50mm and the spacing shall not exceed 600mm.

④ During installation, air vents shall be reserved at the bottom and head of the wall, and the thickness of the wall ventilation layer shall not be less than 20mm. When titanium zinc plate is applied to the interior wall and ceiling in interior decoration, the construction process can refer to the titanium zinc plate wall system.

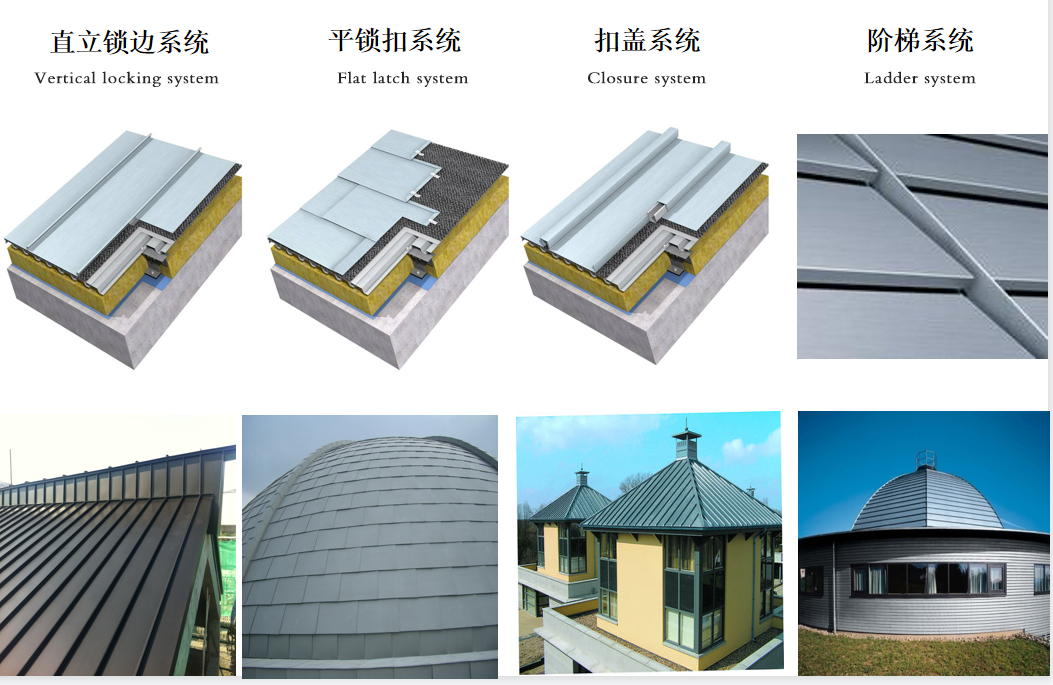

2. Titanium zinc sheet roof system

The roof system can be divided into: vertical locking system, flat locking system, buckle cover system and ladder system.

Source: Shanghai unilite architecture

PS:Matters needing attention

① The applicable gradient of titanium zinc plate is 3 º ~ 90 º, which can be used from very low gradient to vertical gradient.

② The construction of roof system works shall be completed on the reinforced concrete structure or steel structure. It is required that there must be a construction working face before the construction of roof system.

③ During construction and installation, it is recommended to use forming machine and edge locking machine, which can save a lot of construction time and labor cost, and ensure construction accuracy at the same time.

④ During installation, air inlet shall be reserved at the eaves of the roof, and air inlet shall be reserved at the ridge, which shall not be sealed; The thickness of ventilation layer of roof system shall not be less than 40mm.

03.

Application of titanium zinc plate

Public space reconstruction of Huangpu Center

Designer: mi'ao studio

Material application: a total of 11 walls in the East and West halls of the project are covered with steel structure and titanium zinc plate, which are built indoors in an architectural way. The scale is extraordinary, but it still gives people a normal feeling. The unconventional combination method makes the daily activities contained in the small space obtain a stable atmosphere.

Suzhou Suzhou elegant collection

Designer: Shanghai Dushi Architectural Design Office Co., Ltd

Material application: in order to reflect the "thin" of the roof in Wu Guanzhong's works, the building abandons Dai Wa and switches to titanium zinc plate, which is an attempt never seen in Chinese residential architecture. It interprets the implication of ink painting and the elegance of water town more vividly. Titanium zinc plate system roof not only perfectly reflects the design intention in modeling, but also brings more excellent waterproof and thermal insulation performance compared with the traditional tile roof process. It shows the due quality of a modern building in terms of modeling and practical value.

Chongqing Vanke Emerald Park

Designer: Shanghai Riqing Architectural Design Co., Ltd

Material application: the facade design follows the purest building generation logic of "line, joint surface and form body": outline the tall and straight building outline with strong columns and cornice lines; Weave delicate skin with soft metal texture and transparent glass surface; Lines and faces enclose a concise and powerful geometric volume. The modern tension of architecture is expressed through the comparison between rigid and flexible, virtual and real.

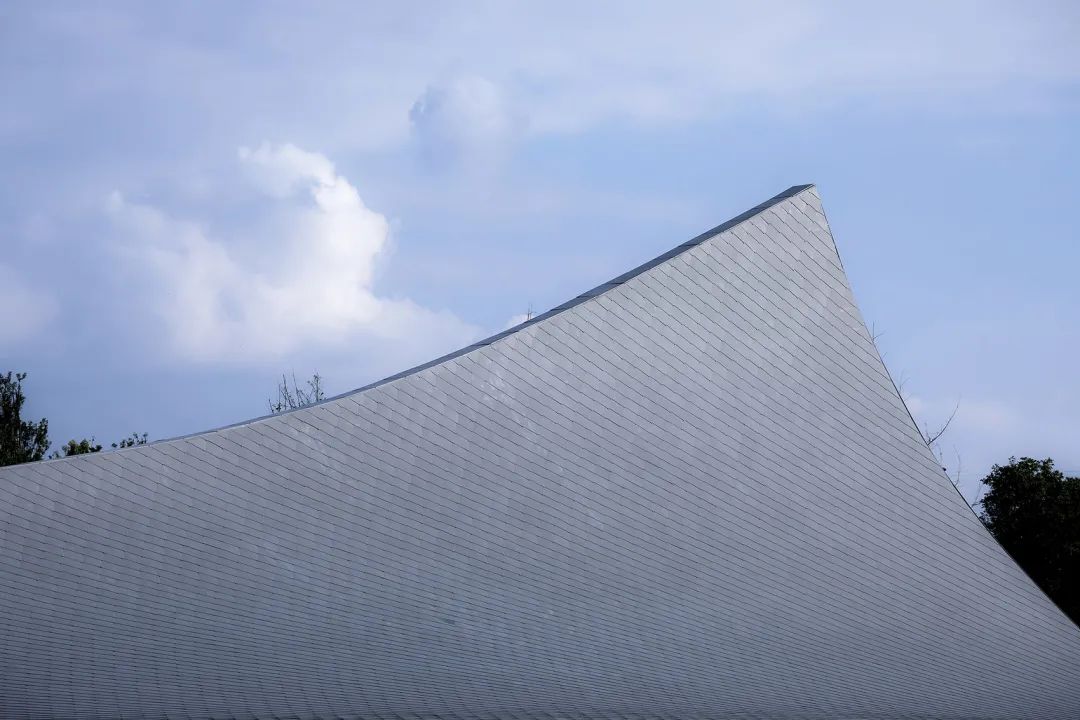

Chengdu xinglonghu CITIC Bookstore

Designer: muda muda architecture

The project is located on the edge of xingshuilong lake, with a rectangular water body as the foundation. It is built on the edge of xingshuilong lake. The building skin adopts imported titanium zinc plate, and the plate surface is arranged in the form of flat latch, forming a unique "fish scale" texture, which complements the sparkling water surface. The architectural texture of titanium zinc plate also echoes the "tile roof" form of traditional slope roof buildings in Western Sichuan.

Datong Sports Center

Designer: populous + CCDI

Material application: the building appearance adopts titanium zinc composite plate material, which organically combines the natural style with earthy smell in Shanxi Province with the modern and community-based free spirit, and the facade of each canopy, regardless of size and material, has been carefully adjusted, such as rough, earthy and solid material. Place it where the audience and tourists can touch it from the ground to enhance their sensory experience; Smooth, sculptural and visually expressive materials are placed on the floor of the main auditorium to continuously integrate into the background and environment of the whole city.

Transferred from: design materials