When it comes to honeycomb structural panels, designers are familiar with them. But there are always various questions when you want to use it. Today, I combed this article on super dry goods for your reference.

01.

What is honeycomb panel?

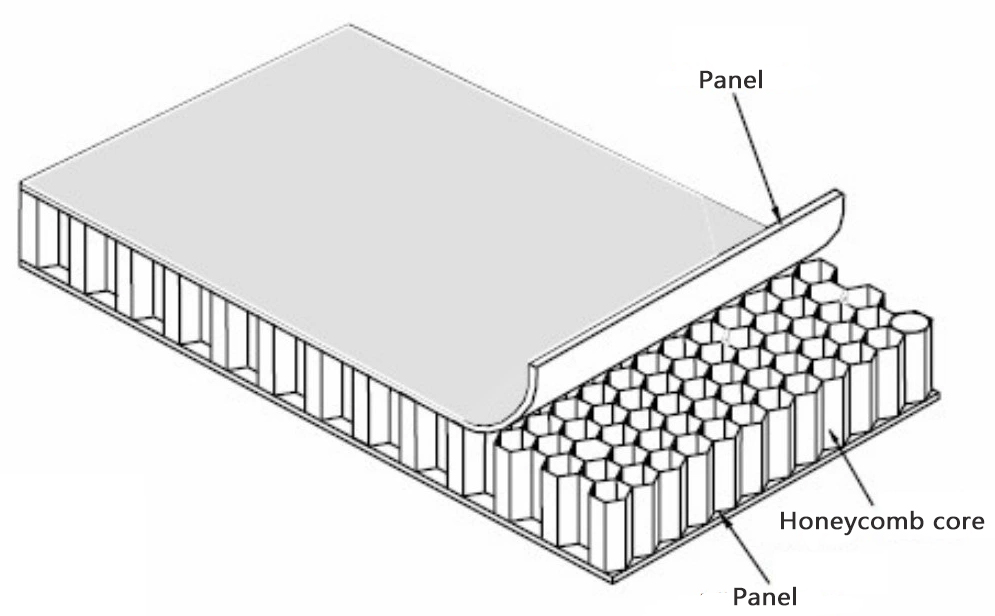

Honeycomb plate refers to the plate made of two thin panels bonded and compounded with honeycomb core materials of different heights, also known as honeycomb sandwich structure.

Why honeycomb core?

Honeycomb panel is a high-strength new environmental protection building composite developed according to the principle of honeycomb structure bionics.

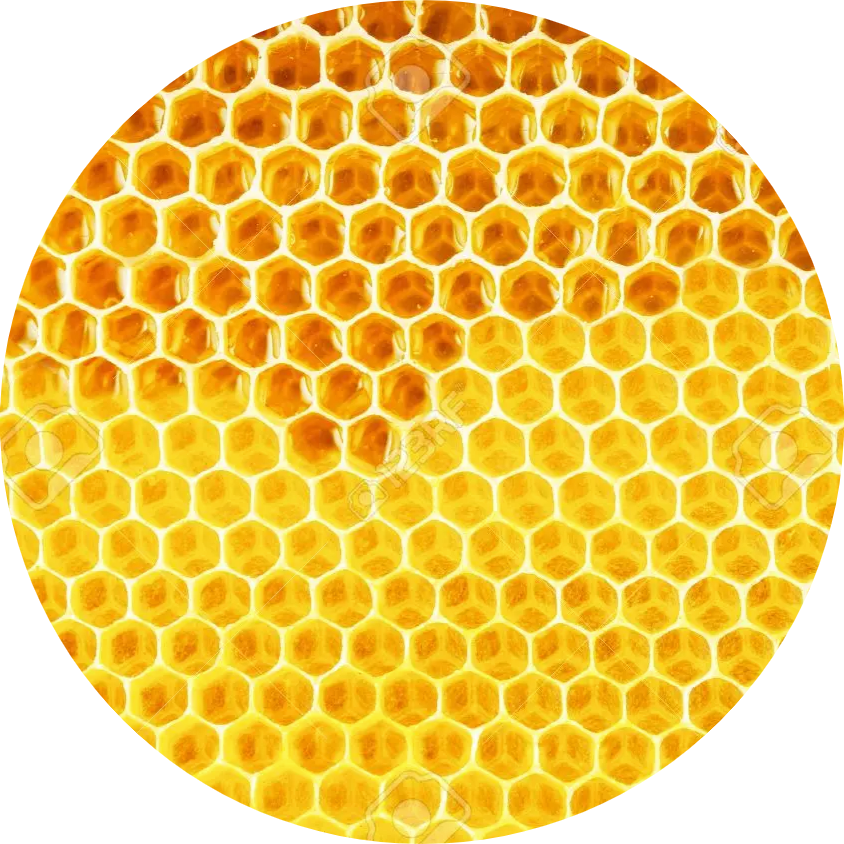

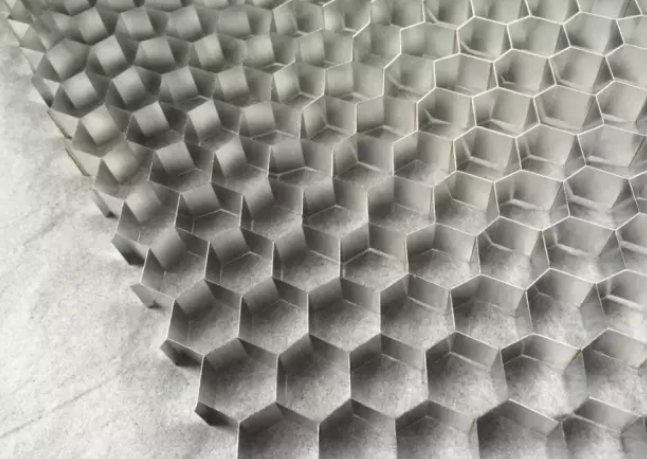

The honeycomb is composed of small hexagonal prism shaped front chambers arranged neatly. The bottom of each small front room is composed of three identical diamonds.

These structures are exactly the same as the obtuse angle of 109 ° 28 'and the acute angle of 70 ° 32' of the diamond accurately calculated by modern mathematicians.

The exquisite characteristics of honeycomb structure

High material utility:

The hexagonal unit of honeycomb has proved to be the structure that saves the most raw materials and creates the maximum space utilization.

High structural strength:

Excellent compression, bending and shear properties.

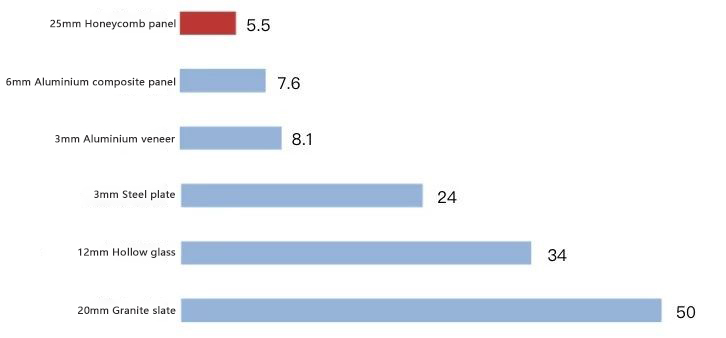

The strength of 25mm honeycomb plate is 15 times that of 3mm aluminum plate, and the stiffness is 128 times.

Sandwich structure (composite structure) can give full play to the tensile and compressive properties of inner and outer metal skins.

Light weight and strong structure:

Large plate surface:

The maximum size of honeycomb plate can reach 2500mm * 12000mm, which is 5 times that of conventional 3mm aluminum plate.

Surface flatness:

Surface materials can be compounded with different materials:

Such as aluminum alloy plate, stainless steel plate, pure copper plate, titanium zinc plate, pure titanium plate, natural stone, wood veneer, glass, etc.

It is easy to install and can be processed into special-shaped plate:

Generally, large installation equipment is not required, which is suitable for the installation of unit curtain wall. The material weight is light and the installation cost is reduced.

Application scope of honeycomb panel in construction field

Honeycomb panel can be used for building curtain wall and interior wall decoration, and can also be used for ceiling. The common honeycomb structural plates on the market are mainly divided into two categories: decorative honeycomb plate and functional honeycomb plate.

Next, let's introduce these two types of honeycomb panels in detail.

02.

Decorative honeycomb panel

The common decorative honeycomb panels in the market include the following types: metal honeycomb composite panels (aluminum, stainless steel, copper, titanium zinc, pure titanium, etc.), stone honeycomb panels, glass honeycomb panels, wood honeycomb panels, cloth honeycomb panels, etc.

「Aluminum honeycomb panel」

Aluminum honeycomb panel is made of all aluminum and has a flat surface. The base plate and core material are made of high-strength aluminum alloy. Compared with single-layer structural plate, it has good thermal insulation and thermal insulation performance, excellent flatness and easy recycling. It is a green environmental protection product.

Composition: face / back plate, adhesive, honeycomb

Material: aluminum alloy AA3003

Thickness: 12, 20, 25, 30, 200mm (customizable)

Specification: 12000mm long * 2500mm wide

Installation: fastener installation horizontal / vertical

Joints: metal joints, glue joints and flat joints

Waterproof: class A1

Formaldehyde: grade E1 (can be directly used indoors)

「Stainless steel honeycomb plate」

The panel is stainless steel plate after special processing technology, the back plate is high-strength aluminum alloy, and the core material is aluminum honeycomb core after anti-corrosion treatment. It is compounded by special adhesive at high temperature and high pressure.

Composition: face / back plate, adhesive, honeycomb

Material: SUS304 / 316

Thickness: 12, 20, 25, 30mm

Specification: W ≤ 2000mm, l ≤ 6000mm

Surface effect: wire drawing, mirror, rice grain, nano anti fingerprint

Installation: fastener installation horizontal / vertical

Joints: metal joints, glue joints and flat joints

Waterproof: class A1

Formaldehyde: grade E1 (can be directly used indoors)

「Copper honeycomb panel」

The panel is copper plate, the back plate is high-strength aluminum alloy, and the core material is aluminum honeycomb core treated with anti-corrosion, which is compounded by special adhesive at high temperature and high pressure.

Composition: face / back plate, adhesive, honeycomb

Material: copper plate (pure copper, copper aluminum composite, copper steel composite)

Thickness: 25, 30mm

Specification: W ≤ 2000mm, l ≤ 6000mm

Surface effect: wire drawing, etching, aging, etc

Installation: fastener installation horizontal / vertical

Joints: metal joints, glue joints and flat joints

Waterproof: class A1

Formaldehyde: grade E1 (can be directly used indoors)

「Stone honeycomb panel」

The natural stone sheet with a thickness of 7mm is combined with aluminum honeycomb plate with high strength and excellent structural stability through aviation composite technology. And equipped with a special installation system, the installation effect not only completely maintains the texture of natural stone, but also greatly improves the installation strength of stone plate. Compared with the traditional stone dry hanging process, it saves 60% of stone resources, 50% of man hours and 60% of matrix load.

Composition: natural stone, adhesive, 20mm aluminum honeycomb plate

Material: marble (3-5mm) granite (5-7mm)

Thickness: 27mm

Specification: 2800mm long * 1400mm wide

Installation: fastener installation horizontal / vertical

Joints: metal joints, glue joints and flat joints

「Glass honeycomb panel」

It is composed of colored glazed glass and aluminum honeycomb plate through aviation composite technology. Compared with the direct use of glass as decorative wall, it has the advantages of high flatness, not easy to deform, break and high safety factor. The special installation system is configured to make it simple and fast without secondary processing in the installation process.

Composition: glass, aluminum alloy surface / back plate, adhesive, aluminum honeycomb

Material: colored glazed glass (multiple colors are available for customers to choose)

Thickness: 20, 25mm

Specification: 3600mm long * 1500mm wide

Installation: fastener installation horizontal / vertical

Joints: open, glue and flat joints

Formaldehyde: grade E1 (can be directly used indoors)

「Wood honeycomb panel」

0.3mm natural wood veneer is compounded with aluminum honeycomb plate by special process. It has high strength and can be recycled, and its fire rating can reach grade A2. It can be processed into surface pinhole shape, and equipped with sound-absorbing paper to achieve good sound-absorbing and noise reduction effect.

Composition: natural wood veneer, aluminum alloy surface / back plate, adhesive, aluminum honeycomb

Material: natural wood veneer (provide a variety of natural wood veneers for customers to choose)

Thickness: 12, 20, 25mm

Specification: 2400mm long * 1200mm wide

Installation: fastener installation horizontal / vertical

Joints: open, glue and flat joints

Formaldehyde: grade E1 (can be directly used indoors)

Fire rating: A2

「Fabric honeycomb panel」

Aluminum honeycomb plate and facing cloth are bonded by environmental protection two-component polyurethane adhesive pressing plate. This special structure can effectively absorb acoustic energy and reduce vibration frequency and intensity, so as to achieve the function of sound absorption and noise reduction. It saves material, time and labor, and has low total installation cost. It is more suitable for ceiling, internal wall partition and other internal decoration of high-end office buildings, cinemas and dramas in hotels.

Composition: facing cloth, aluminum alloy surface / back plate, adhesive, aluminum honeycomb

Material: provide various styles and fabrics for customers to choose

Thickness: 10, 12, 15mm

Specification: 8000mm long * 1200mm wide

Installation: fastener installation horizontal / vertical

Joint: flat joint, metal cover type

Formaldehyde: grade E1 (can be directly used indoors)

03.

Functional honeycomb panel

The common types of functional honeycomb boards in the market are sound-absorbing board, thermal insulation sound-absorbing board and anti-collision honeycomb board.

「Sound absorbing board」

The perforated sound absorption is compounded by special aviation technology. While meeting the installation strength, it can realize the sound absorption function, and the noise reduction coefficient (NRC) = 0.75. It can be processed into arc plate, corner plate and other special-shaped plates without secondary processing on site or installation.

Composition: surface / back plate, adhesive, sound-absorbing paper, aluminum honeycomb

Material: aluminum alloy AA3003

Sound absorbing paper: soundtex sound absorbing paper, non-woven fabric

Surface perforation rate: according to design requirements

Thickness: 10, 12mm

Specification: 6000mm long * 1500mm wide

Installation: hook up installation

Joint: 3mm

Fire rating: A1

「Thermal insulation and sound absorption board」

It integrates thermal insulation decoration and sound absorption functions, and is suitable for conference rooms, concert halls, lobbies, workshops, etc. Places with high requirements for sound absorption and noise reduction. At the same time of sound absorption, the cooling and heating can be controlled below the ceiling to meet the requirements of energy conservation and environmental protection.

Composition: surface / back plate, adhesive, sound-absorbing paper, aluminum honeycomb

Material: aluminum alloy AA3003

Sound absorbing paper: soundtex sound absorbing paper, non-woven fabric

Surface perforation rate: according to design requirements

Thickness: 10, 12mm

Specification: 6000mm long * 1500mm wide

Installation: hook up installation

Joint: 3mm

Fire rating: A1

「Anti collision honeycomb panel」

The difference between anti-collision honeycomb panel and ordinary honeycomb panel is that its anti-collision performance is twice that of standard aluminum alloy honeycomb panel. It is often used for decoration of wall parts vulnerable to impact (such as wall skirt below waist line), places with large flow of people and high impact resistance requirements: such as station, shopping mall, cinema, library and other wall decoration. It can be used in combination with standard aluminum alloy honeycomb plate.

Composition: surface / back plate, adhesive, epoxy fiberglass board, aluminum honeycomb

Material: aluminum alloy AA3003

Thickness: 12, 20, 25mm

Specification: 8000mm long * 1500mm wide

Installation: fastener installation horizontal / vertical

Joints: metal joints, flat joints, flat joints

Fire protection: class A1

Formaldehyde: grade E1 (can be directly used indoors)

04.

Application of honeycomb panel on building curtain wall

「Want ultra narrow joints, neat and clean without glue?」

There is a honeycomb panel curtain wall system favored by architects, that is, pic-j3 flat joint sealed honeycomb panel curtain wall system, whose joint width is only 3mm.

Product structure and specification

Surface / back plate: high-precision aluminum alloy, stainless steel, copper, titanium zinc (customized)

Aluminum honeycomb: high strength aluminum alloy hexagonal honeycomb, anti-corrosion treatment

Panel coating:pre roll fluorocarbon baking paint / special surface texture treatment (such as wire drawing / mirror / aging / embossing / magic color)

Coating color:the color conforming to international ral standard shall be provided according to design requirements

Standard thickness: 25, 30mm (thickness for customers to choose)

Plate type: standard plate, arc plate, corner plate and special-shaped plate

Fire rating: A1 (non combustible)

Its advantages include:

1、Meet the requirements of thermal expansion and cold contraction of metal curtain wall;

2、The plate surface does not need riveting, and there is no mechanical damage;

3、3mm flat joint, can be divided by large plate surface, and the building facade is more concise and beautiful;

4、EPDM dry sealing strip is used for sealing and waterproof design to ensure air tightness and water tightness and meet the four property requirements of curtain wall;

5、The installation is not affected by the season, so as to solve the problem that glue cannot be applied on the construction site in winter in the north.

It has been tested and certified by the national authority: the air tightness and water tightness have reached the highest level 4 and 5 respectively, the wind pressure resistance is level 8, and the in-plane deformation is level 3, which fully meets the requirements of the national standard of metal curtain wall.

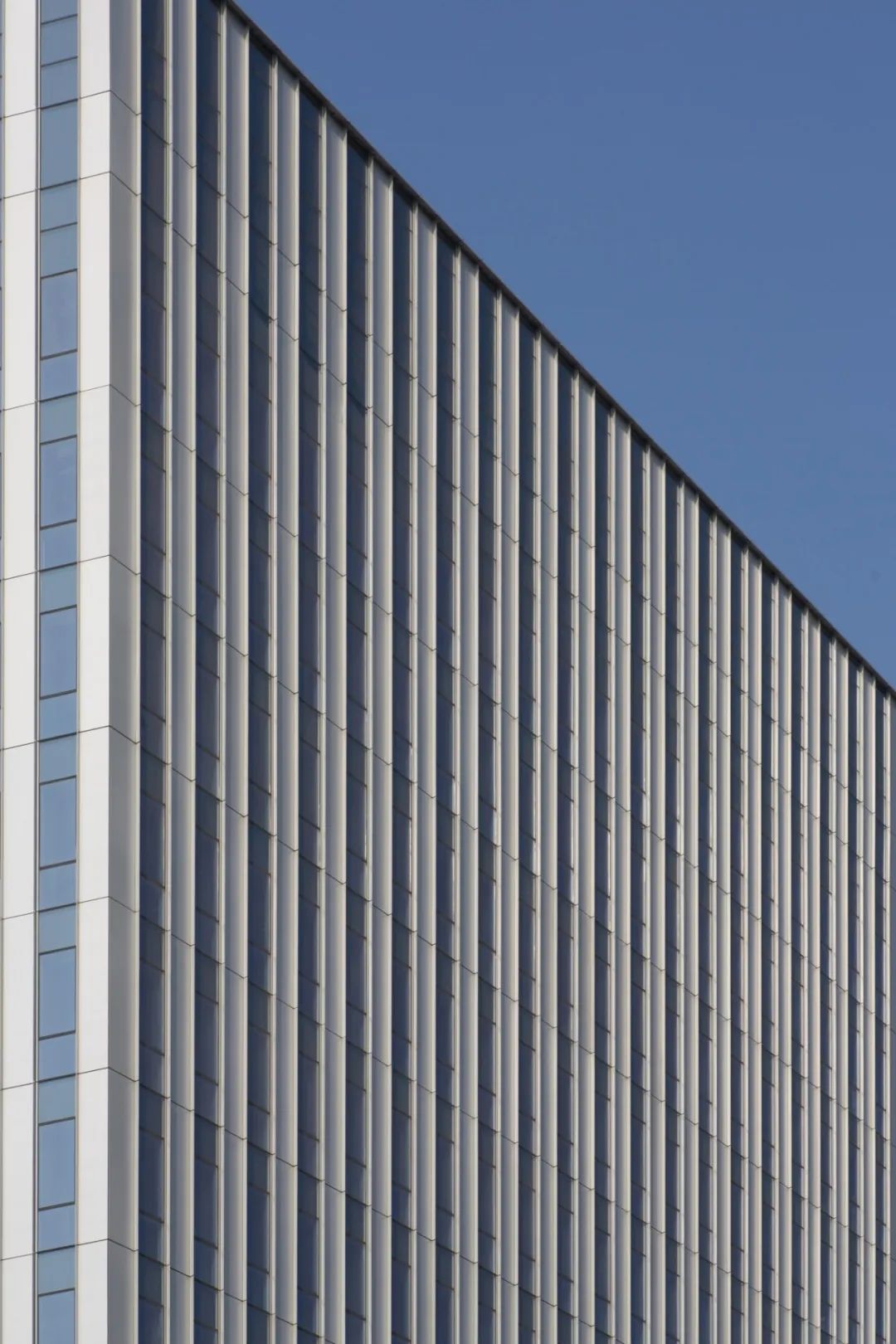

「Application case」

Tianjin Binhai airport terminal

The curtain wall system installed on the back can complete the installation of honeycomb panels at the cornice without scaffold. It not only does not affect the construction progress of the working surface under the cornice, but also saves the cost of the scaffold.

Qingdao CTV animation City

The plug-in installation method is adopted, and the maximum specification of the honeycomb plate is nearly 10m long, and excellent flatness is maintained. At the corner of the exterior wall, an integrated seamless corner board is used to outline the three-dimensional and smooth outline of the building. It took only two months from the project order receiving to the completion of wall slab construction.

「Application as sunshade and line decoration」

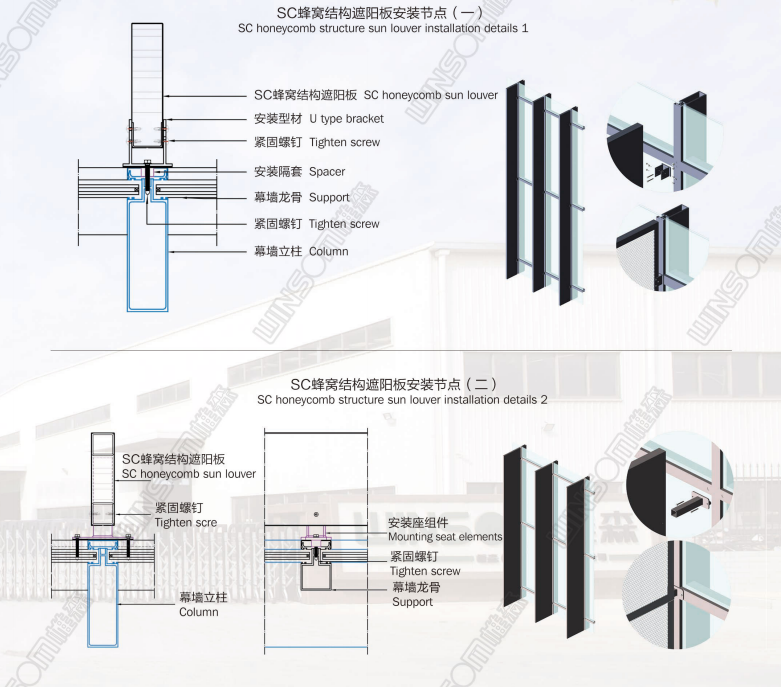

Here we want to talk about the SC honeycomb structure sunshade, which is no longer used as plane decoration, but vertical and facade, opening a new trend of building sunshade and line decoration.

Product structure and specification

Panel: aluminum alloy AA3003

Core material: aluminum honeycomb core, high-precision aluminum alloy AA3003, with anti-corrosion treatment

Back plate: aluminum alloy AA3003

Reinforcing profile: 6063-T5

Thickness: 36、50、70、100、120、150、180mm

Density:≤800mm

Length: ≤6000mm

Its advantages include:

1、 The integrated seamless corner structure is adopted, with exquisite and lightweight appearance;

2、Built in aluminum alloy profile to ensure the wind load resistance and installation strength of the plate;

3、Compared with the fluorocarbon coating on the pre roll, it has excellent weather resistance and durability;

4、Compared with traditional extruded profiles and aluminum veneer components, it has more weight advantages and effectively reduces the building load;

5、The super large size brings more plasticity to the architectural decoration style.

「Application case」

China rice paper Museum

The honeycomb panels used in the project are not used for the facade decoration of the wall, but are hung outside the glass curtain wall and stacked horizontally to create an open rice paper shape. In order to avoid downward bending of large-size plates, profiles with a certain thickness are placed inside each plate to ensure that the plate can maintain excellent flatness and installation strength for a long time.

Woolworths global supermarket chain

In this project, sc50 honeycomb sunshade shutters of 31 different colors are used as sunshade and decoration materials to be installed on the facade of the supermarket, and the wind load resistance and installation strength of the board are increased by built-in aluminum alloy profiles. It also has excellent strength when used as shading and line decoration of high-rise buildings.

The surface coating adopts pre roll fluorocarbon baking paint process, which has excellent weather resistance and corrosion resistance, so that the plate has uniform and long-lasting color.

「Installation node」

Transferred from: material online