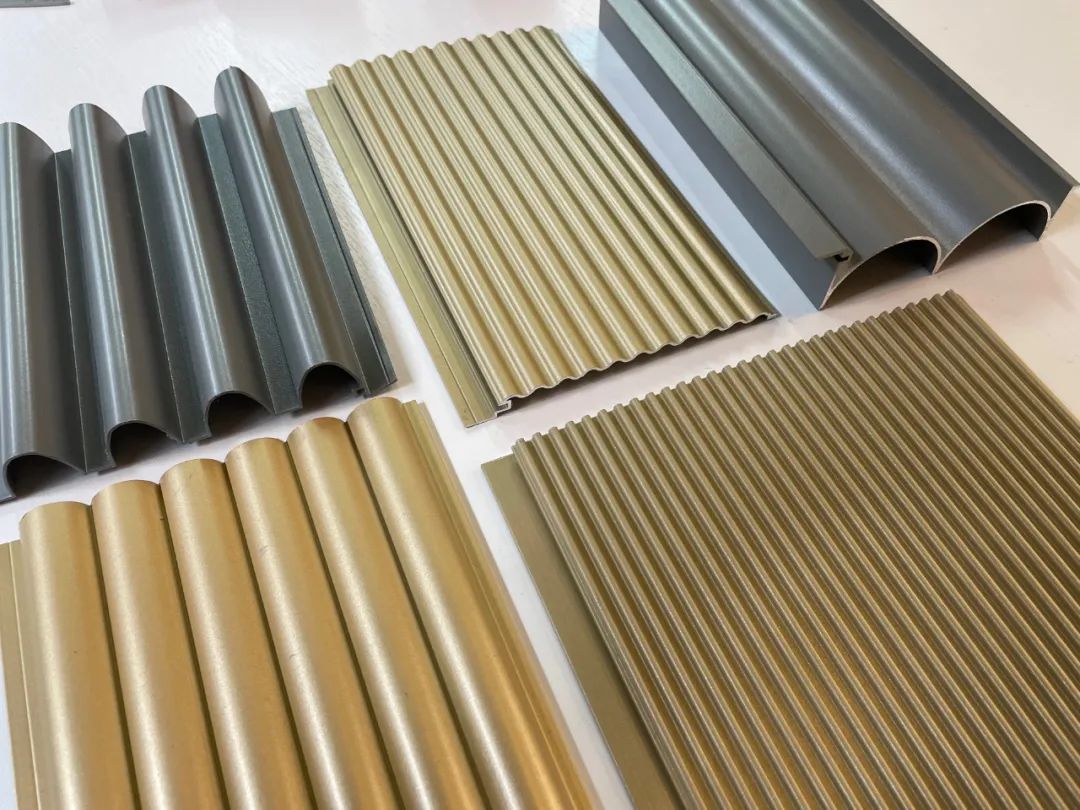

With the popularity of light luxury, more and more forms of finished metal molding plates appear, enriching the choice range of designers. Don't think that metal is just tough. In fact, it will have a more distorted and flowing effect, like the "Mercury object" in previous science fiction films.

The most popular is the popular aluminum wave plate. So, what is the aluminum wave plate and why do many international famous interior designers like to use it?

01.

What aluminum wave plate?

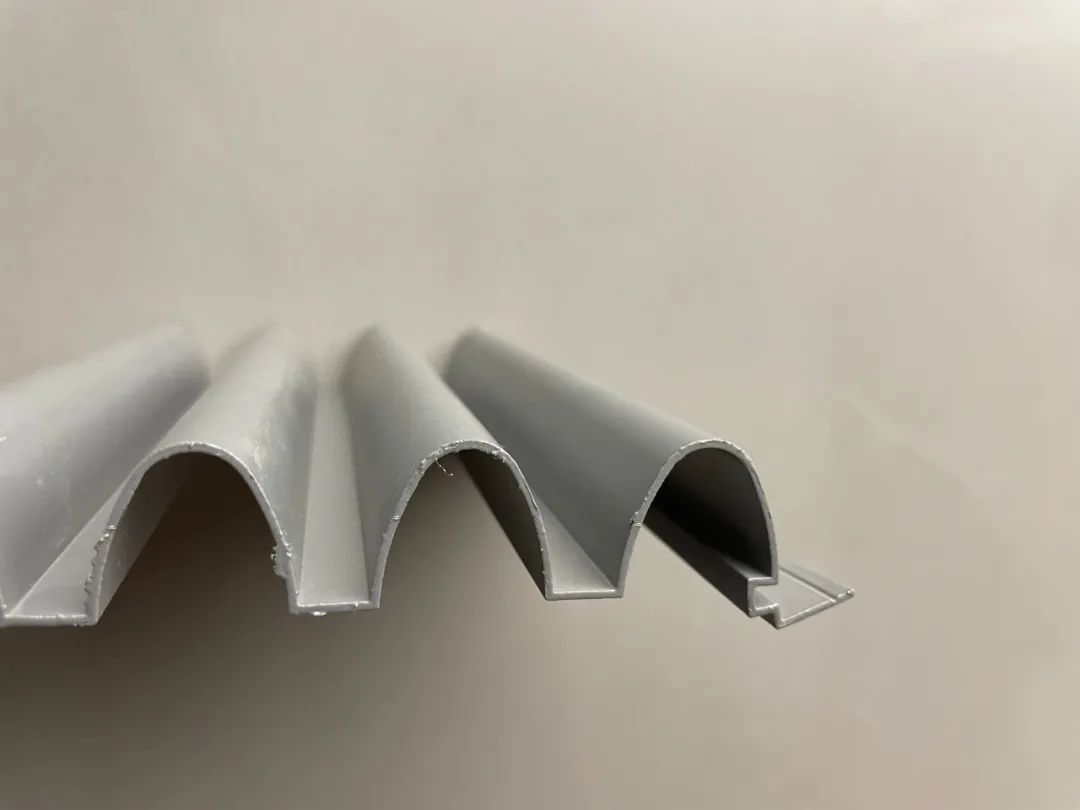

Aluminum wave plate, as the name suggests, is a product formed by machine or continuous bending. It can create the fashion trend effect of different design styles, which is composed of two methods: plan and three-dimensional.

Stainless steel, aluminum, brass, chrome... And all shiny, reflective metallic materials have been rejected as "too old-fashioned" and rejected by avant-garde design. But who could have thought that the trend is always turning, and the outdated elements will turn over one day.

Aluminum wave plate has smooth lines, strong three-dimensional sense, obvious layering effect, elegant and beautiful buildings and a sense of rhythm.

02.

Material characteristics of aluminum corrugated plate

「Light weight」

「High strength」

High strength can be achieved through composition configuration, processing and heat treatment.

「Good anti rust ability」

The formed oxide layer can prevent metal oxidation and corrosion.

「Diverse and beautiful surface treatment」

It can be anodized, electrophoretic, chemical treatment, polishing and painting.

「Good plasticity and easy processing」

「Good electrical conductivity」

「Easy installation」

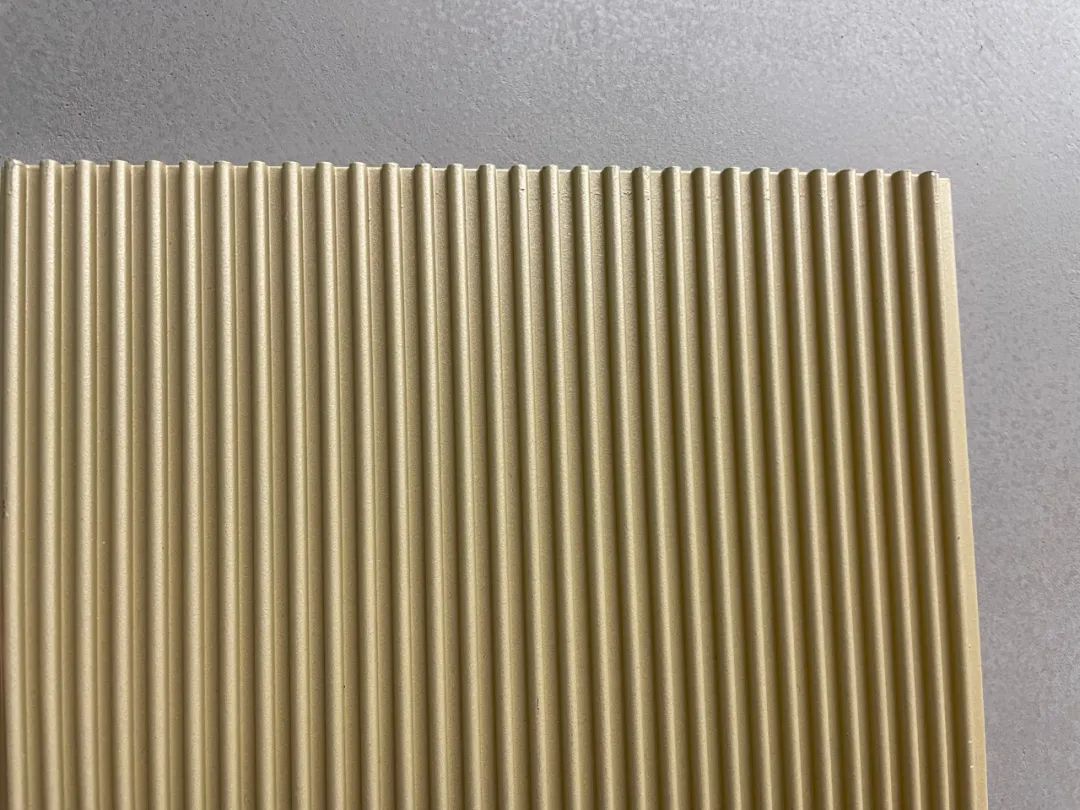

Aluminum wave plate has unique typical sine wave smooth lines, especially showing its complex and exquisite peculiar effect. Various installation methods, i.e. horizontal, vertical or diagonal installation. It can not only cooperate with the complex panel structure, but also easily realize the visual layered effect between curtain wall panels. The subtle effect produced by the interleaving of light and shadow can create a fascinating visual feeling in a large area, and inject retro futuristic aesthetics into the modern interior style.

03.

Application case

「X&Collective Design」

STARNET Advertising agency · Double sided space

We integrate the front desk and two meeting rooms into an independent box, which can minimize the use space and enhance the sense of agglomeration of the box space through the treatment of old metal and corrugated plate.

「Chau Doc A three story house in a village」

The roof is composed of three groups of butterfly structures. Although it is the same familiar metal wave plate, the external opening area becomes larger, but it still retains the rain shielding effect of the eaves.

The metal wave plates are staggered in layers to achieve the effect of shading and rain protection, and the staggered spacing can maintain ventilation.

「西安·TSINGTAO 1903 Qingdao Beer City Restaurant」

From the entrance to the dining area, then to the bar area and the hall, its form and layout have experienced the transformation from "simple" to "complex", and have been implanted into the stage performance area with the middle of the bar as the core, highlighting its associated theme.

The golden metal wave plate gives people a visual sense of pushing forward layer by layer, reflecting the space to the end and integrating it into the whole dining area. Under the light mapping, it appears to be flowing and colorful.

「Capture the natural light and shadow, poetic life -- Yaju music & Greenland · Yunhe Center」

The second and third layers are cantilevered metal boxes, which are sprayed with pure white fluorocarbon aluminum folded plates. The aluminum folded plates and the solid plates are arranged according to the size change law, just like the sail about to set sail.

The stylish shiny metal surface is the coolest, and it's solid and reliable. With wavy line modeling, it will slightly weaken some cold and hard feeling, but still not reduce the cold temperament. Next, we have to take a look at its construction technology.

04.

Construction technology

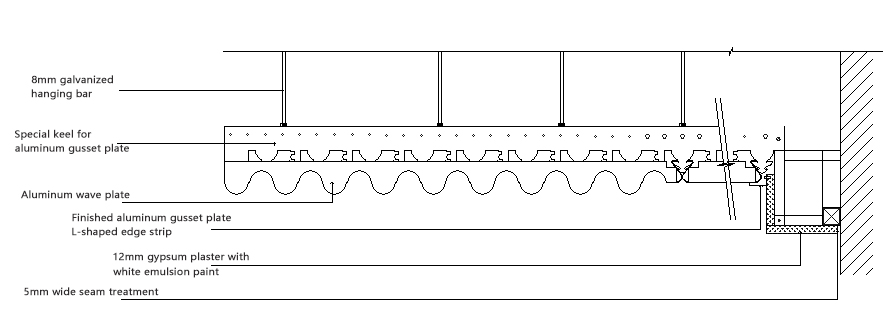

「Technological process」

Setting out - Installing suspender - Installing keel - Installing aluminum plate + Detail adjustment and treatment.

「Snap line of base course」

After the basic materials are prepared, the center point of the room is the center, and the grading position line of the keel is drawn on the wall.

「Installation of main ceiling」

The ceiling installation needs to be fixed on the ceiling with expansion bolts.

「Installation of main keel」

C38 light steel keel is generally selected as the main keel, and the spacing is controlled within 1200mm.

「Installation of side keel」

According to the clear height requirements of the ceiling, 2525mm paint baking keel shall be fixed around the wall with cement nails, and the spacing of cement nails shall not be greater than 300mm.

「Installation of secondary keel」

The secondary keel is hung on the main keel through the hanging suspender. While hanging the secondary keel, connect the opposite ends, straighten them first and then fix them.

「Install sheetmetal」

Set a datum line in the middle of the assembly area along the direction perpendicular to the secondary keel, and then align the datum line and install it on both sides respectively.

Aluminum wave plate, it is exquisite and gorgeous. No matter what color and style of interior decoration match, it will immediately improve the gorgeous degree of the space and evolve into many more interesting designs.

Transferred from: material online