"Architectural curtain wall has become an important symbol of modern architectural culture, architectural personalization, architectural art and new science. In the process of rapid development of the industry, the third generation curtain wall material - high scratch resistant porcelain aluminum veneer has entered the market with its environmental protection characteristics, superior performance and more attractive price in the whole process from raw materials to production technology, maintenance and recycling Construction market. "

01.

What is baking varnish aluminum veneer?

Coating

The coating adopts green, non-toxic and healthy coating porcelain.

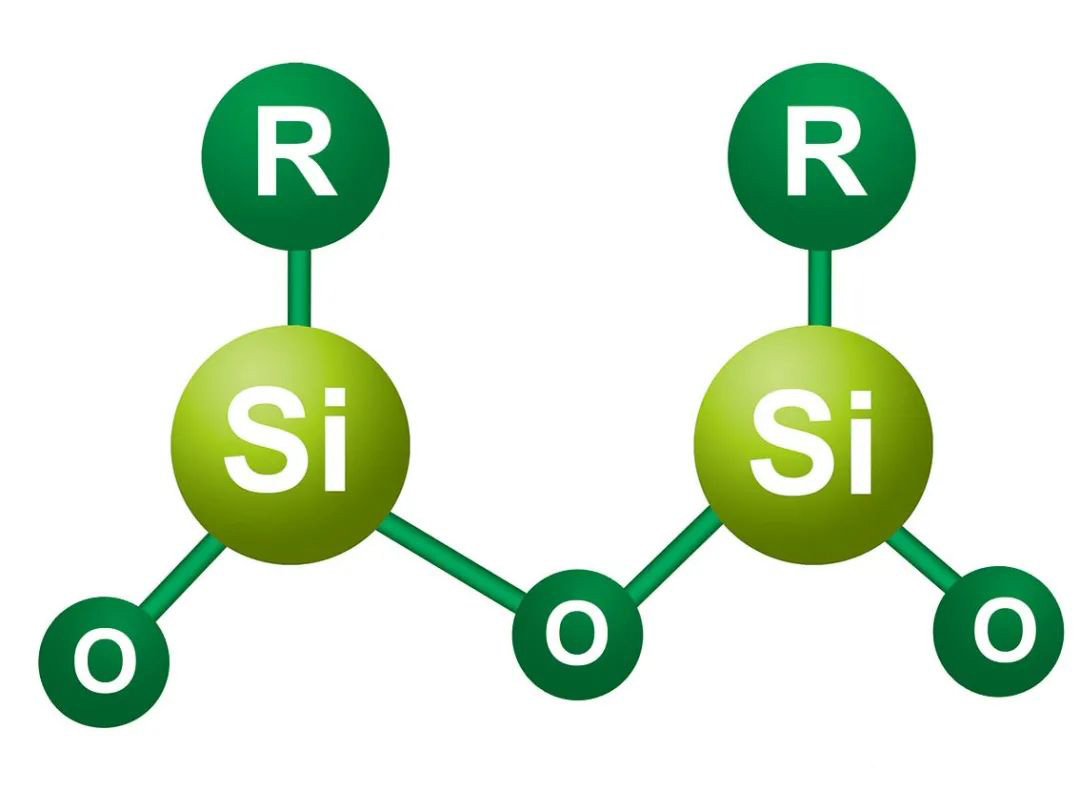

The main components of porcelain fused to metal coating are Si and O. there is no need to add PFOA additives in its manufacturing and production process, so it is a completely green, environmental friendly, non-toxic and healthy coating.

Chemical molecular structure diagram-1

Chemical molecular structure diagram-2

The ceramic coating is made of aluminum alloy and dried by hardening and drying. The ceramic coating is made of the latest technology of sol gel (sol-gel), which is the most advanced material research in the world. It not only realizes the inorganic material composite of nanotechnology, but also overcomes the defects of the brittleness and toughness of traditional ceramics.

Porcelain coating will not be aged by ultraviolet, acid rain, automobile exhaust and air pollution like organic coating, and give better corrosion resistance. It is a semi permanent material; The low surface energy of porcelain coating and the ability of inorganic materials to eliminate static electricity make it not adhere to pollutants in the atmosphere, always maintain a gorgeous appearance and have self-cleaning. The porcelain coating has extremely high hardness and scratch resistance.

Integrating the characteristics of porcelain fused to metal coatings, special colors, excellent durability, semi permanence, pollution resistance, incombustibility and low-carbon environmental protection performance, it provides a new concept of architectural decoration materials for the new century.

02.

Production process

Treatment before coating

Compared with the second generation curtain wall materials, the pretreatment process is optimized. For the second generation of materials, the pretreatment methods are: degreasing → water washing → pickling → water washing → chromizing → water washing → drying. The degreasing agent is divided into alkaline degreasing agent and acidic degreasing agent. Alkaline degreasing agent is composed of phosphate, carbonate, sulfate, caustic soda and a small amount of surfactant. Its environmental pollution factors include phosphorus, COD, suspended solids, grease, etc. Acidic degreasing agent is generally composed of organic acid and surfactant. It has a slight impact on the environment, mainly including cod, suspended solids, oil, etc.

Acidic liquid can be hydrochloric acid, sulfuric acid and phosphoric acid. Generally, a small amount of acid mist inhibitor should be added. Acid mist inhibitor is mainly composed of surfactant and corrosion inhibitor. The amount of acid mist inhibitor is very small, about 0.5% - 2%. The impact of pickling solution on the environment includes phosphorus, iron, COD, suspended solids, etc. (there is no phosphorus pollution in hydrochloric acid and sulfuric acid pickling solution), and the pollution degree is relatively light.

For the treatment process of aluminum alloy, the activation solution is generally composed of sulfuric acid, nitric acid and hydrofluoric acid, with low concentration and light environmental pollution. The main components of neutralizer are carbonate and caustic soda, which will affect the pH value of water body.

The surface conditioner is composed of colloidal titanium phosphate, with low concentration, generally 0.2% - 0.3%, no water washing, and little impact on the environment.

Chromizing agent is divided into chemical oxidation treatment agent for aluminum alloy and water-free conversion treatment agent for color steel plate. It mainly contains hexavalent chromium and trivalent chromium, which pollutes the environment with hexavalent chromium ions.

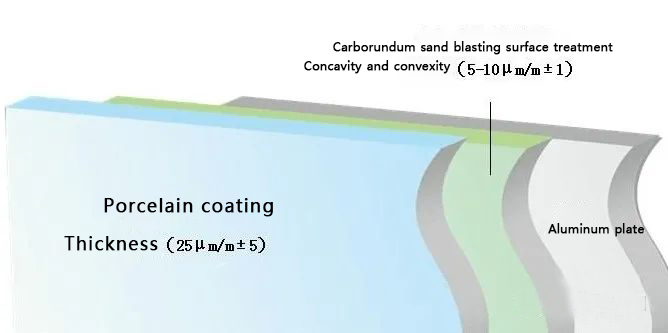

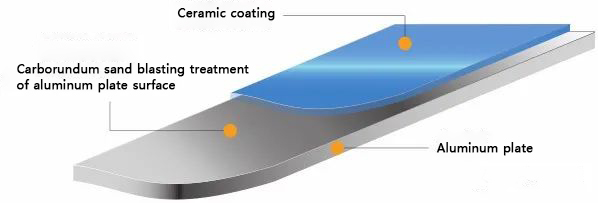

Therefore, in the pretreatment process, the pretreatment process of the second generation material has a slight impact on the environment, while the treatment process of the third generation material - high scratch resistant aluminum plate is as follows: sand blasting → water washing → drying. During the design of the used physical treatment and sand blasting equipment, the sand and ash separation design shall be done well, and the exhaust outlet shall be provided with protective measures, so as to reduce the impact on the environment to zero.

Spraying process

In the spraying process, the heating sintering temperature is different from the previous materials. The curing temperature of this material is only 180 ℃, while the curing temperature of the second generation curtain wall material is 200 ℃ - 230 ℃. The sintering temperature of some special materials is as high as 800 ℃ - 1000 ℃, which greatly reduces the energy consumption.

It is not difficult to see that energy conservation and consumption reduction can not only achieve the purpose of saving energy and improving energy utilization efficiency, but also reduce the emission of pollutants, and alleviate the crisis caused by the shortage of energy resources to a great extent. Energy saving is particularly important in this case.

In terms of production technology, porcelain aluminum plate embodies the concept of environmental protection.

Fire protection characteristics and environmental protection embodiment of recycling process

It is fire-proof and nonflammable, and does not produce toxic gases such as fluorine and other organic coatings in case of fire. Because the porcelain coating can be cleaned by sand blasting, the product realizes physical treatment and recycling. From the perspective of product fire protection characteristics and recycling process, porcelain fused to metal embodies the concept of environmental protection.

03.

Superior performance

And porcelain fused to metal aluminum veneer have the following superior performance characteristics:

1. Strong weather resistance: it is mainly composed of inorganic materials, and its structure is silica structure. Therefore, the porcelain coating will not be as easily exposed to ultraviolet light as the organic coating. Acid rain. Automobile exhaust gas and air pollution damage and aging, which is a semi permanent material.

2. Nonflammability: when the film burns at 1500 ℃ for two minutes, it only changes color without decomposition. It is a nonflammable decorative material.

3. Combination of rigidity and flexibility: the coating not only has good rigidity, but also has certain flexibility when subjected to impact, and the coating has reached an optimal balance between rigidity and toughness. This can even be adjusted through production.

4. Corrosion resistance: porcelain enamel sol not only has physical "anchoring" adhesion with the substrate during film formation, but also has chemical bond generation, preventing the invasion of water and electrolyte. We have done some experiments on strong acid and strong alkali, which show that it has strong acid-base resistance.

5. Pollution resistance: the ability of inorganic materials to eliminate static electricity makes it difficult to adhere to pollutants in the atmosphere and always maintain a gorgeous appearance.

6. Scratch resistance: because the coating of porcelain aluminum plate can have a maximum hardness of 6h, it has very high hardness, strong scratch resistance and wear resistance.

7. Multicolor: it can provide a variety of colors, adjust the gloss within a certain range, and provide plain color, metal flash, pearlescent and other appearance effects, so as to meet the different requirements of buildings for color and luster and provide a broader space for designers.

8. Antibacterial property: due to its compact surface structure, strong acid and alkali resistance, high scratch resistance and other properties, bacteria cannot fall on its surface and reproduce, which can effectively inhibit the breeding of bacteria and molds. Therefore, it is widely used in medical and purification industries.

Fujian children's Hospital

The above performance characteristics can improve the current construction market pattern from the perspectives of fire prevention, scratch resistance, appearance color, anti-corrosion, weather resistance and antibacterial.

With the significant improvement of people's social awareness of environmental protection, fire prevention and health, porcelain aluminum veneer is expected to become the front end of decorative materials, gradually replace the original traditional aluminum veneer, become the first choice of owners and designers, and lead the qualitative leap of curtain wall material industry.

Some content transferred from the network.