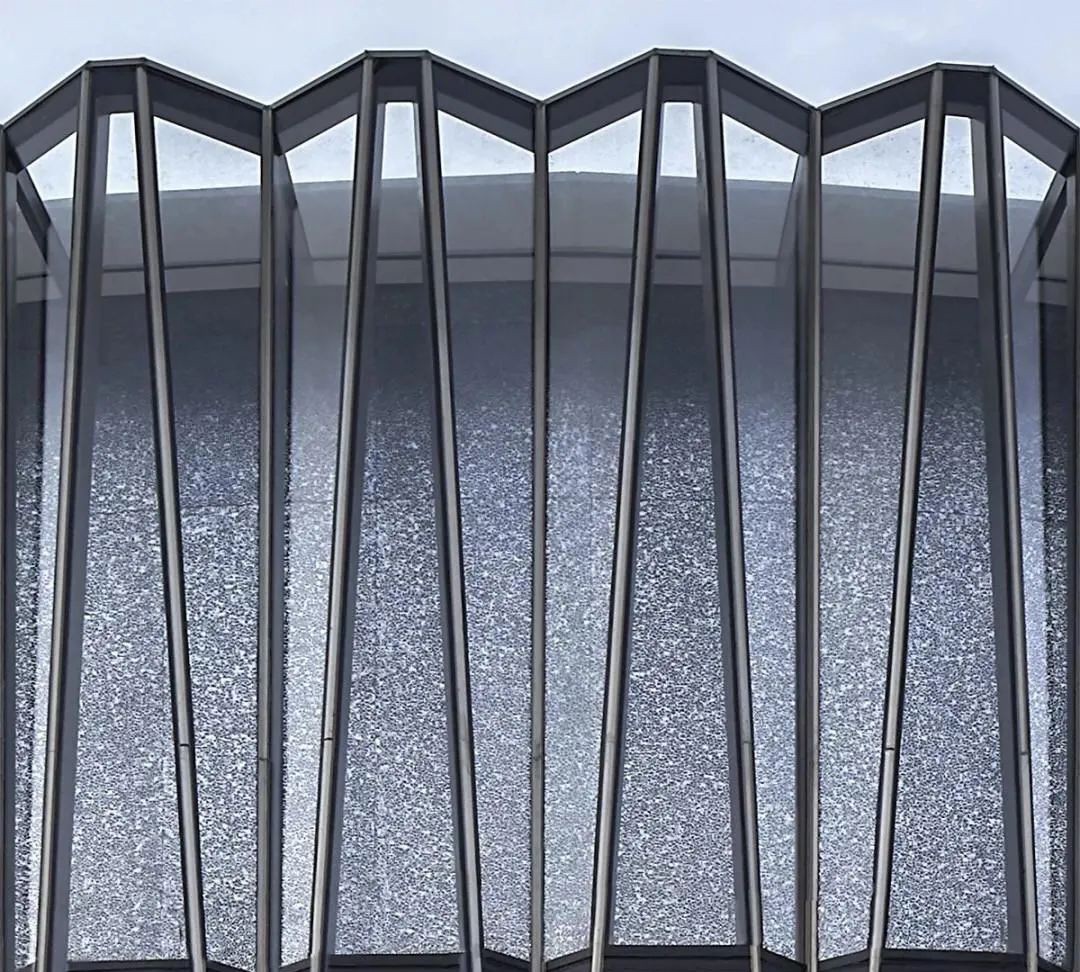

▲Dive in: Desert, Palm Desert, California, USA × Part of 2019 Art Exhibition

01.

What is aluminum foam?

Aluminum foam is made from pure aluminum or aluminum alloy by adding foaming agent, and then has the characteristics of metal and bubble. The process is to melt molten aluminum alloy into foam box and form liquid foam into air, and then form the desired shape after curing the liquid foam.

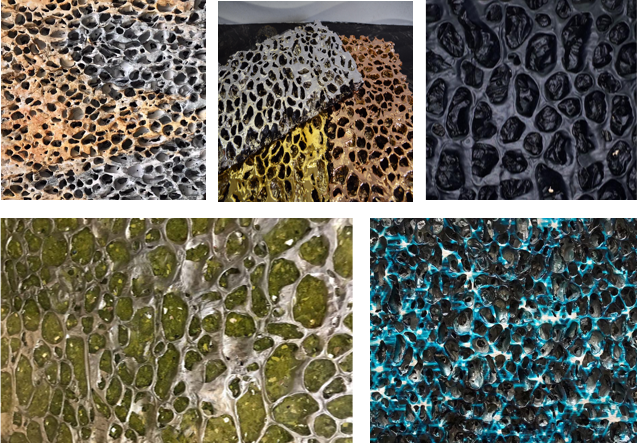

▲Aluminum foam with metal and bubble characteristics at the same time

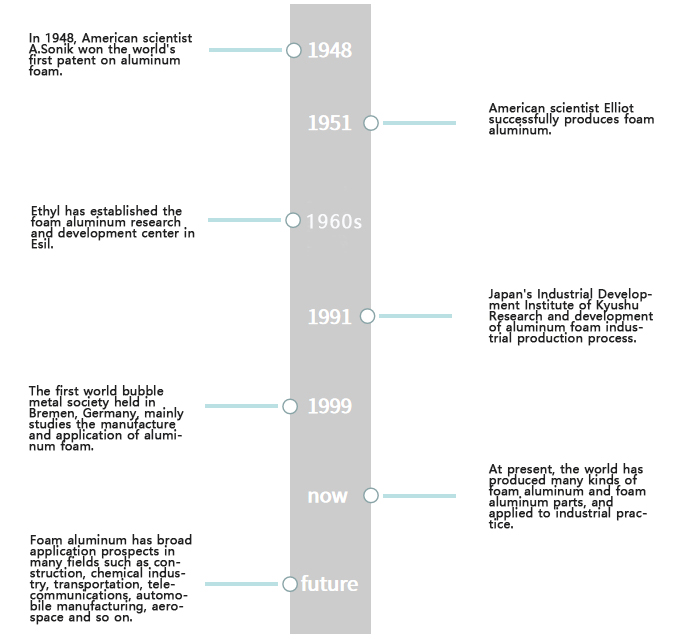

Development history of aluminum foam

With the development of science and technology, conventional materials (metal, concrete, ceramics, etc.) are far from meeting the requirements of human beings in some structural design, especially in energy absorption and buffer design.

Human beings have gradually turned their attention to porous structural materials. The emergence of aluminum foam has opened new ideas for designers.

Properties of aluminum foam

Ultralight

.The density is 0.2-0.4g/m ³, About 1 / 10 of aluminum density, 1 / 20 of titanium density, 1 / 30 of steel density and 1 / 3 of wood density.

Sound absorption

Aluminum foam can absorb the energy of sound through the vibration of stomata, which is used for silencing.

Heat resistance

The aluminum alloy has a high heat resistance. The dissolution temperature of the ordinary aluminum alloy is 560-700 degrees. The single foam aluminum is not heated to 1400 degrees immediately, and it does not release toxic gas at high temperature.

Electromagnetic wave shielding

Aluminum foam has a good shielding effect on high frequency electromagnetic waves, and can reduce electromagnetic interference by more than 80%.

Properties of aluminum foam materials

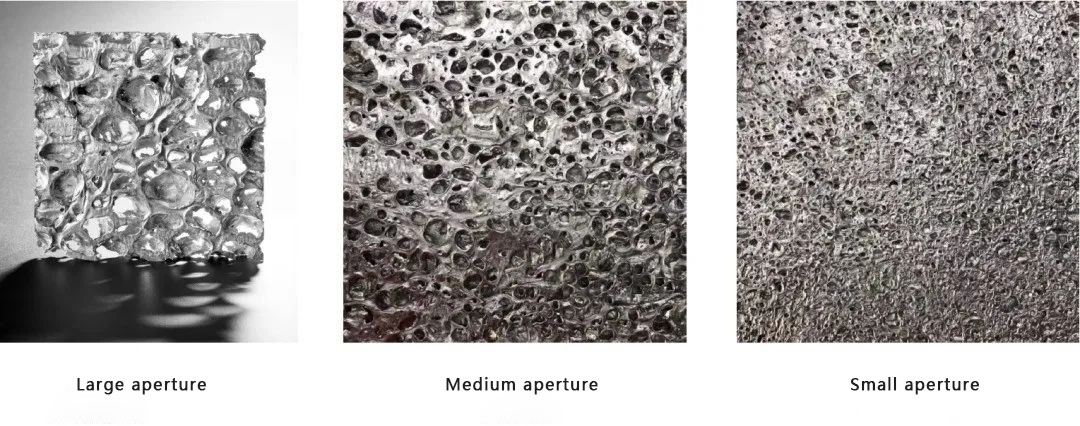

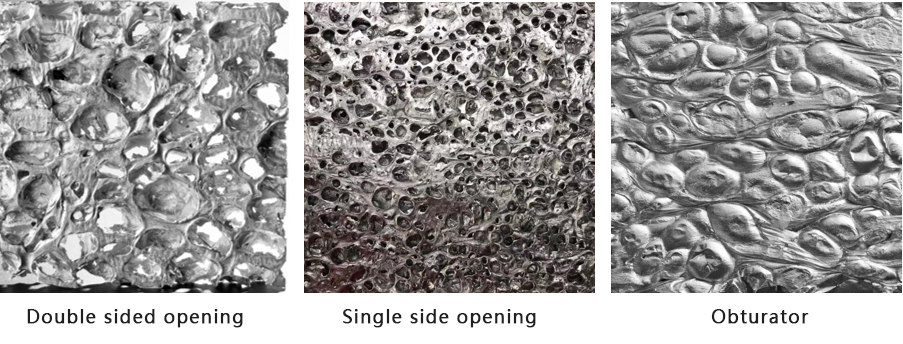

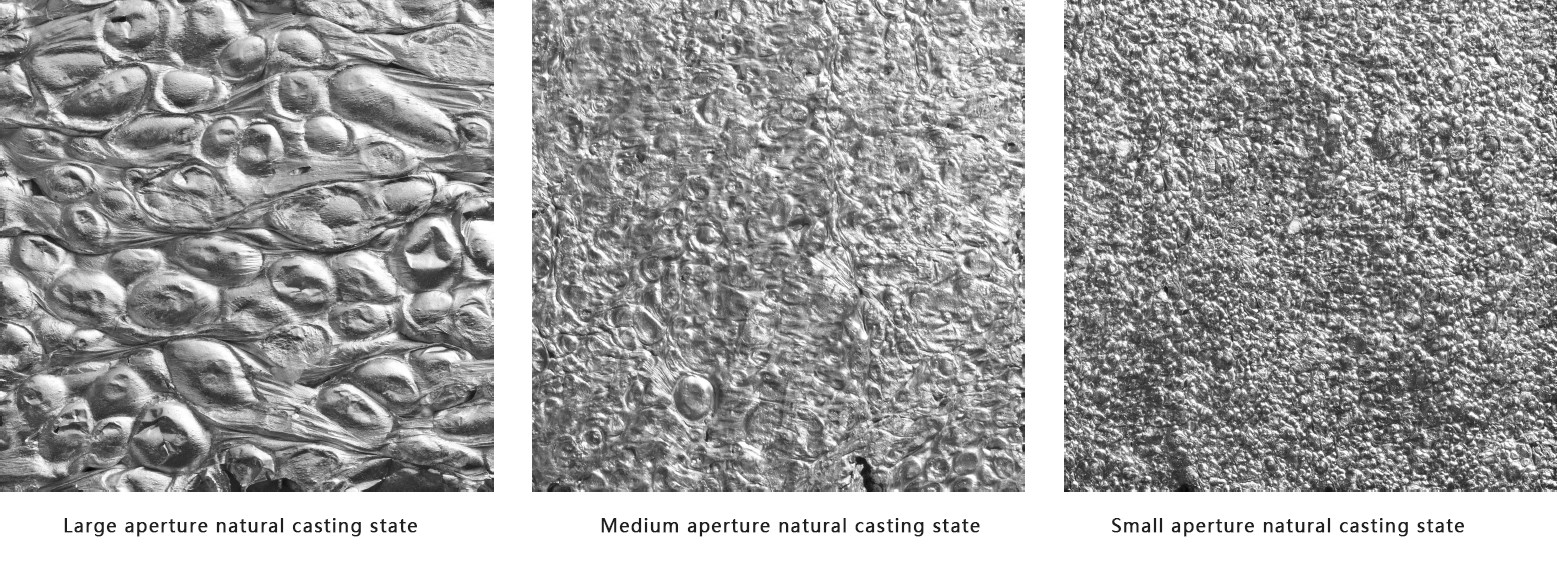

Foam aluminum can be divided into 3 specifications: large aperture, medium aperture and small aperture. Each specification is divided into one side opening, two side opening, and natural casting state (double-sided closure). The diversified specifications can provide more space for designers to diversify their design.

The standard size of foam aluminum plate is 1220. × 2440mm,1220 × 3660mm.

The length of standard width plate can be made according to the actual demand, up to 6000mm.

The standard thickness is 12.7mm and 25.4mm, and the large orifice plate can be 43.2mm thick. The big hole natural casting aluminum foam plate can reach 9.5mm, and is applied to the industrial field.

▲Aluminum foam plates of all sizes

And designers can spray paint colors for foam aluminum plates according to their design concept, and can fuse with marble, resin and other materials, and collide with the sparks of art.

▲Colorful aluminum foam panels

Scenario application

Foam aluminum can be designed by changing its density and pore structure to design the required comprehensive properties. It has the characteristics of light weight, high strength, sound absorption and noise reduction, fire resistance, corrosion resistance, low thermal conductivity, easy processing and installation, and beautiful texture.

In addition to being widely used in building facade, indoor wall ground and ceiling sound absorption, it can also be commonly used in machinery manufacturing, aviation industry, automobile manufacturing and other fields.

Building facade

▼

Interior wall and floor

▼

Ceiling sound absorption

▼

02.

Foam aluminum design case

Palm Desert, California, USA

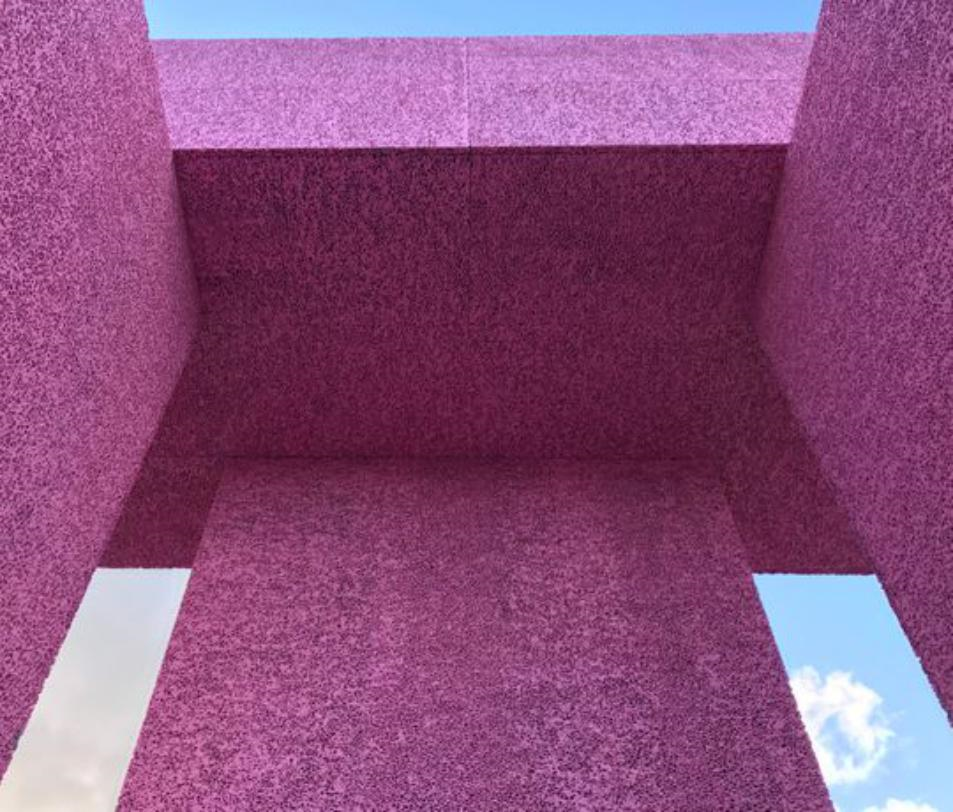

Dive-In:Desert × Part of 2019 Art Exhibition

Design:Superflex

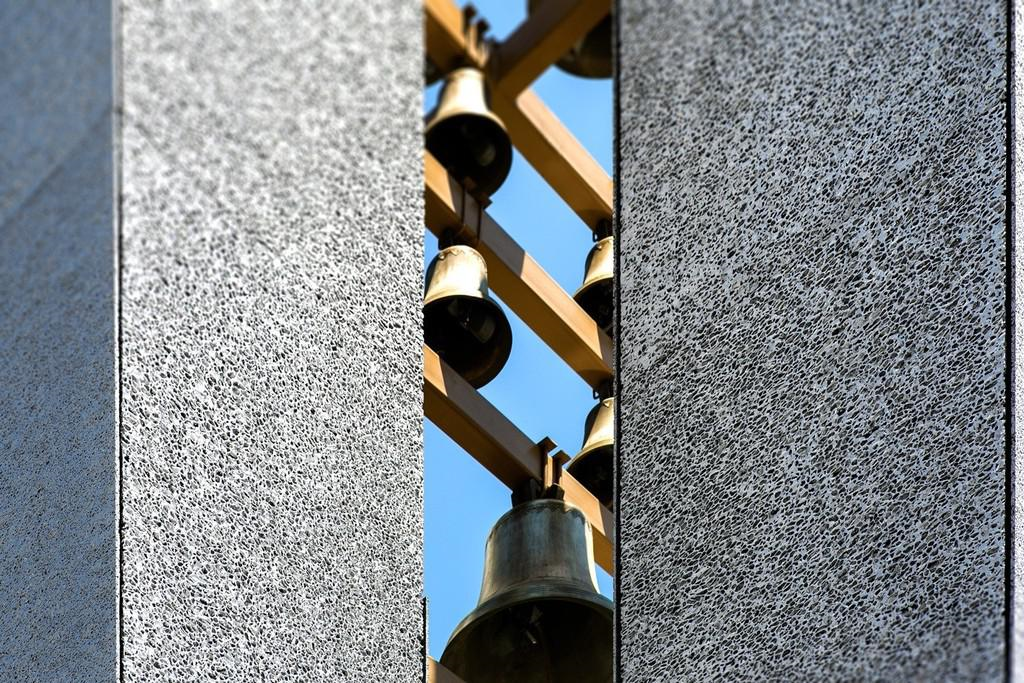

Chilean Bell Tower Square

Design:Jaime EdisScalpeiio

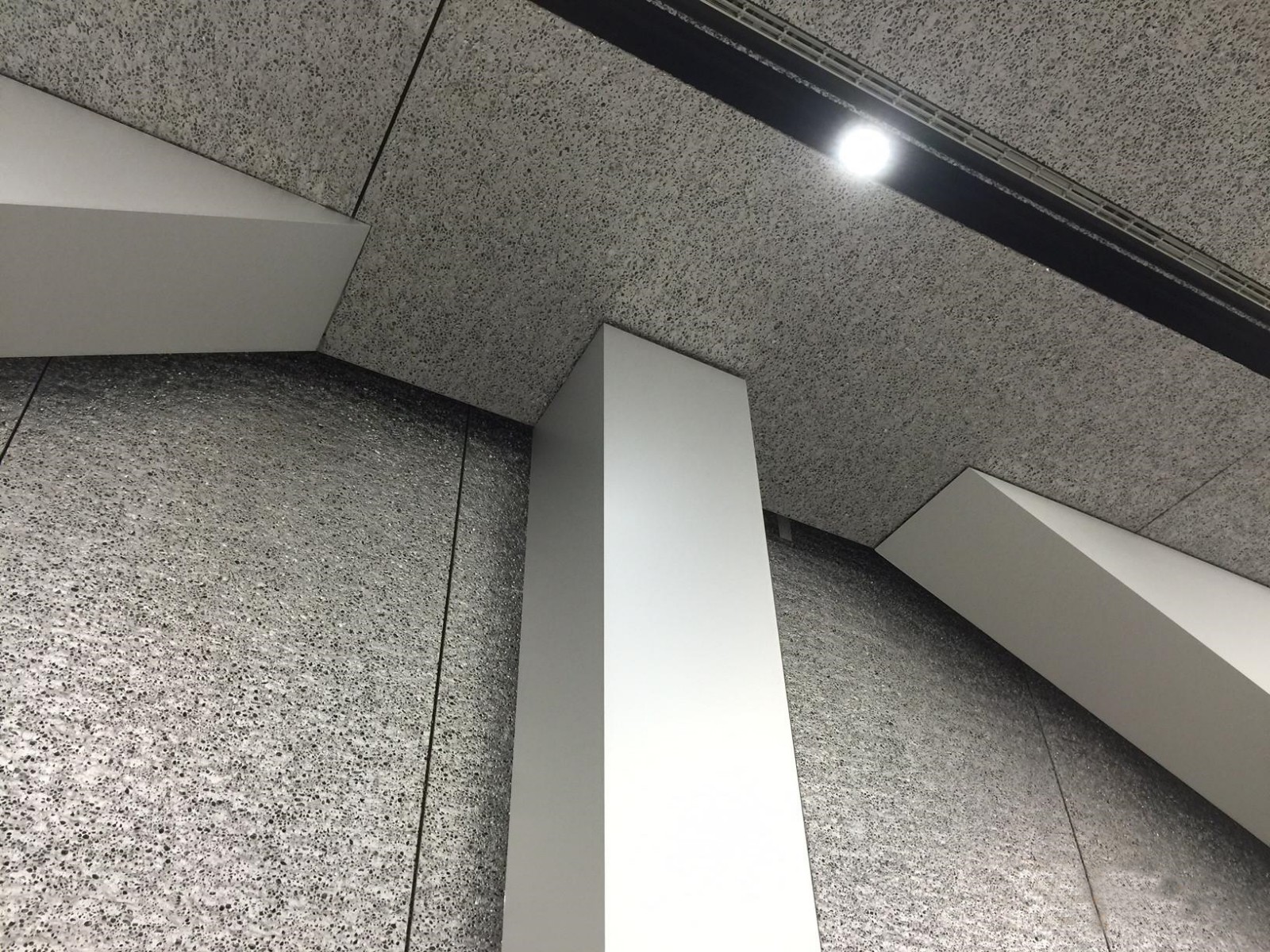

Haolilai concept store

Design:DAS Lab

Prada Art Museum

Design:OMA

911 Memorial Museum

Design:Davis BrodyBond

Seville new cultural center, Spain

Design:Guillermo Vásquez Consuegra

Shanghai Huangpu huile tea

Design:Qinhuangdao Mozhu Decoration Engineering Co., Ltd

Wenzhou jindijiangshan Yipin Sales Office

Design:Shanghai PTArchitects Design Consulting Co., Ltd

Transferred from: Design materials