In the previous article, we said that aluminum veneer refers to building decoration materials processed by different surface treatment technologies after chrome treatment.

At the same time, we also analyze the advantages and disadvantages of aluminum veneer and the reasons for its popularity. Today we continue to learn about other related knowledge of aluminum veneer.

1. BASE MATERIAL

The aluminum substrate used for aluminum veneer is mainly 1100h24, 3003h24 / 5005h24 and other types of single-layer aluminum alloy (hereinafter referred to as series 1, 3 and 5). The most obvious difference between them is the type and content of the main alloy metal.

1 series aluminum is made of pure aluminum, and the aluminum content is as high as 99%. The corrosion resistance is good, but the rigidity cannot be strengthened by heat treatment. Therefore, the strength is about 10% lower than that of 3 series.

3 series aluminum contains 1% - 1.5% manganese element. It belongs to aluminum manganese alloy. It has anti rust function. The board surface strength and plasticity are good. It can be easily processed into various decorative aluminum products.

5 series aluminum contains about 3% - 5% magnesium element, also known as aluminum magnesium alloy. It has low material density and high tensile strength. Compared with other aluminum alloy products, aluminum magnesium alloy has lighter weight and wide decorative uses. The only disadvantage is that the magnesium content cannot exceed 5%, otherwise the brightness of the product surface will decrease.

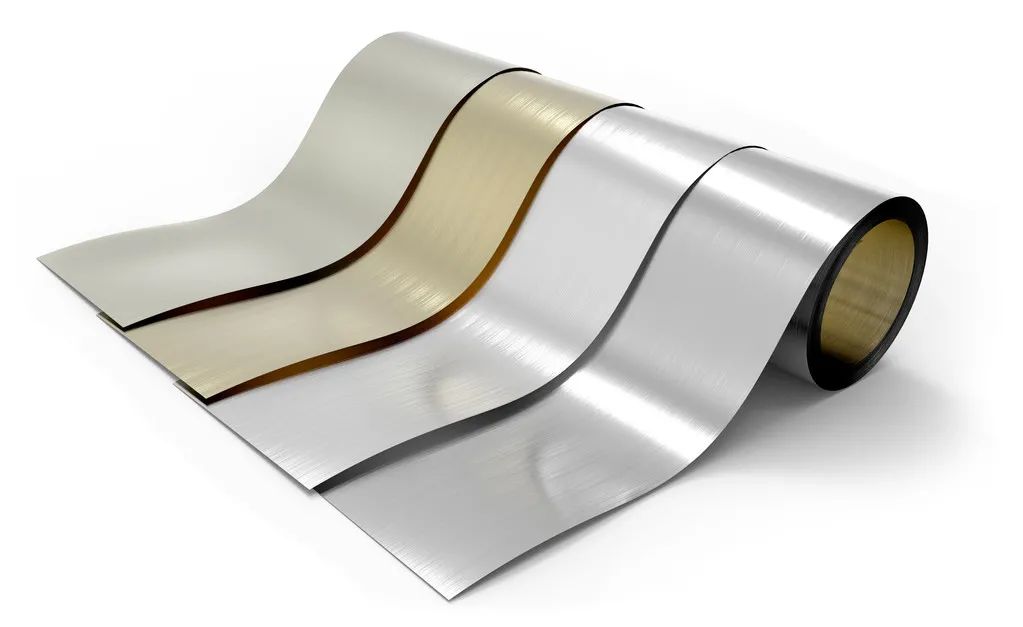

2. STRUCTURE

The structure of aluminum veneer is mainly composed of panel, stiffener, lug (corner code) and other parts. The conventional thickness is 1.5mm, 2.0mm, 2.5mm and 3.0mm. When required, thermal insulation mineral wool can also be added to the back.

The lug can be bent directly from the panel, or it can be additionally installed at the place of the panel.

3. SURFACE

Aluminum veneer surface: generally, one coating, two coating, three coating and four coating are adopted. The main technology is two coating and one baking, three coating and two baking, four coating and three baking, etc. At present, most of the processes used are three coating and one baking, four coating and two baking, and their coating properties can meet the aama2605-98 standard.

4. TYPE

As for the types of aluminum veneers, the common division methods are mainly as follows: first, according to different application occasions, aluminum veneers can be divided into indoor aluminum veneers and outdoor aluminum veneers.

However, this is a relatively broad division, and there is no obvious definition of the thickness of the aluminum substrate and its surface treatment.

5. THICKNESS

Secondly, if the adopted aluminum substrate thickness is taken as the standard, it can be simply and clearly divided into 1.2mm aluminum veneer, 1.5mm aluminum veneer, 2.0mm aluminum veneer, 2.5mm aluminum veneer and 3.0mm aluminum veneer.

6. TECHNOLOGY

Finally, if divided according to the shape and common process of aluminum veneer, it is like stone like aluminum veneer and wood like aluminum veneer.

Art carved aluminum veneer

Punching aluminum veneer, hyperbolic aluminum veneer, arc aluminum veneer, spherical aluminum veneer, and so on.

(Some pictures in Chinese are from the Internet)