PVDF is the abbreviation for polyvinylidene fluoride resin, which has excellent properties such as aging resistance and chemical resistance. As an important component of coil coatings, it is applied to building roofs and walls with extremely high weather resistance requirements. This coating cannot assimilate at room temperature and must be baked at 249 ° C or above to form a film.

FEVE is the abbreviation for polytetrafluoroethylene alkyl vinyl ether copolymer or gas olefin alkyl vinyl ester copolymer resin. The coatings made from this resin have high gloss, high transparency, and excellent weather resistance. It can crosslink and cure at room temperature, or adapt to high temperature curing.

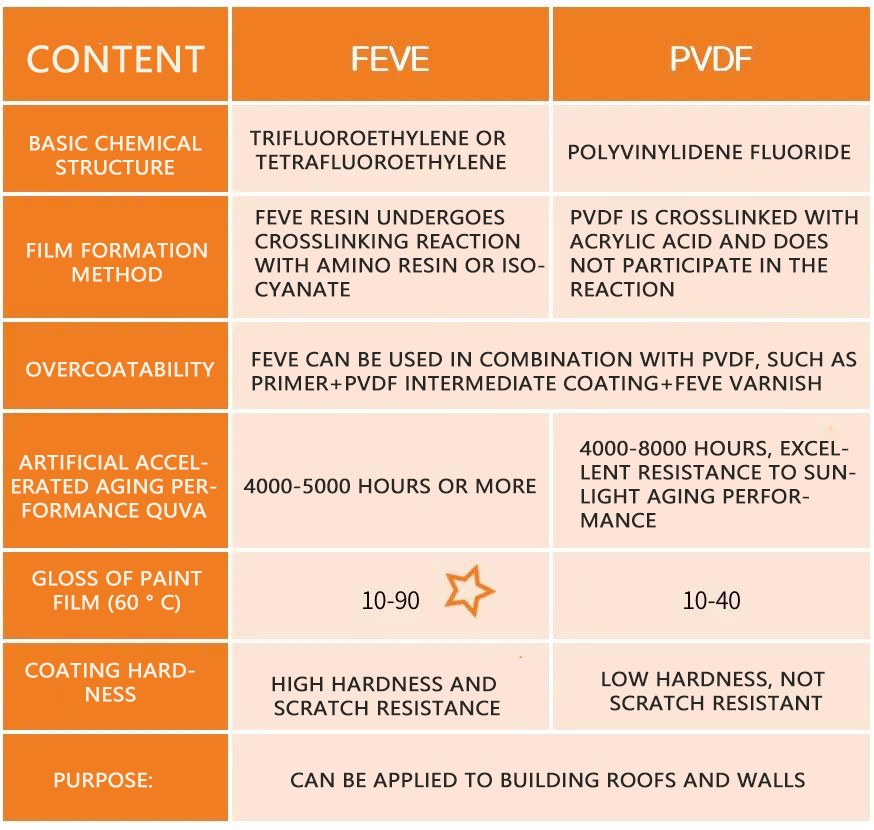

We use a table to compare the similarities and differences between FEVE and PVDF9:

·FEVE coating weather resistance ≤ PVDF

·FEVE coating hardness>PVDF

·FEVE: Higher gloss, can be blended with more vibrant colors.

When it comes to fluorocarbon coatings in the metal composite decorative materials industry, everyone's first reaction is PVDF oxygen carbon resin coatings. PVDF fluorocarbon refers to coatings with fluororesin as the main film-forming substance; Also known as carbon paint, coating fluororesin coating, etc., PVDF fluorocarbon coating, as the most widely used and mature coating in the industry, has excellent weather resistance and other indicators. Among various coatings, fluororesin coating has particularly superior performance, weather resistance, heat resistance, low temperature resistance, chemical resistance, and unique non adhesiveness and low friction due to the high electronegativity of the introduced fluorine element and strong carbon fluorine bond energy. After decades of rapid development, fluorine coatings have been widely used in various fields such as construction, chemical industry, electrical and electronic industry, machinery industry, aerospace industry, and household goods. Becoming the highest comprehensive performance coating brand after high-performance coatings such as acrylic coatings, polyurethane coatings, and silicone coatings. The widely used fluororesin coatings mainly include three types: PTFE, PVDF, FEVE, etc.

But since 2021, with the surge in demand for PVDF resin for lithium batteries, the price of 142b resin, an upstream raw material for PVDF, has skyrocketed, leading to a significant increase in the price of PVDF fluorocarbon coatings and severe supply shortages. The significant increase in PVDF resin has caused a tight supply of PVDF fluorocarbon coatings, resulting in price increases. As another product of the fluorocarbon family, FEVE fluorocarbon coatings have begun to appear in everyone's sight. Here, we will take you to re-examine FEVE fluorocarbon coatings, PVDF, and FEVE, both of which are called fluorocarbon coatings. So what exactly is fluorocarbon? The first "fluorocarbon coating" was born in 1938, which is commonly known as DuPont's Teflon coating, consisting of copolymers such as polytetrafluoroethylene (PTFE) and perfluoroalkoxy (FEP). This type of material is known as the "corrosion-resistant and non stick Teflon" due to its unique and excellent heat resistance (180 ℃ -260 ℃), low temperature resistance (-200 ℃), self-lubricating properties, and chemical stability. Fluorocarbon paint is generally divided into three fluorine and four gas types., PTFE has higher anti-corrosion performance. Due to the extremely high liquefaction temperature required during use, the dispersibility of pigments is poor, so it has only been used in non stick pans, medical, aviation and other fields, and has not entered the construction industry.

It was not until 1965 when Pennwalt Company in the United States successfully developed fluorocarbon coatings for construction based on polyvinylidene fluoride (PVDF) (trademark Kynar 500) that fluorocarbon coatings were commercialized, and people saw the application prospects of fluorocarbon coatings in the construction field. Tens of thousands of buildings around the world shone brightly under the protection of PVDF fluorocarbon coatings. Due to the fact that this type of coating is still a baking type coating, although the baking temperature is much lower than polytetrafluoroethylene, about 230 ℃, it cannot be used on site and requires factory processing, which also restricts the further promotion of fluorocarbon coatings. It was not until 1982 that Japan's Asahi Glass Company developed the gas olefin vinyl ether copolymer (FEVE), which pioneered the development of room temperature curable fluororesins that could dissolve in aromatic hydrocarbons, lipids, and ketone solvents at room temperature. It overcame the disadvantage of fluorocarbon coatings that could not cure at room temperature and achieved the ideal of coating fluorocarbon coatings on construction sites, greatly expanding the application field of fluorocarbon coatings.

Compared with PVDF fluorocarbon coatings, the main characteristics of FEVE fluorocarbon coatings are as follows:

1.FEVE coating has a lower baking curing temperature of 216-224 ℃, which can save more energy consumption;

2.The maximum solid content of the coating can reach over 70%, and the VOC (≤ 420g/L) emissions during the coating process are lower, which is more in line with environmental protection requirements:

3.FEVE coating has high glossiness and hardness, making it more suitable for aluminum veneer products that are sprayed after bending and forming;