Currently, countries around the world have increasingly strict requirements for building safety, and fire performance is an important indicator of safety. In recent years, the occurrence of multiple major fires in high-rise buildings has attracted high attention from relevant departments. The Ministry of Public Security and the Ministry of Construction have jointly issued multiple regulations to establish mandatory standards for fire prevention requirements of building decoration materials.

GB 50016-2014 "Code for Fire Protection Design of Buildings" clearly stipulates the requirements for the fire resistance level of materials in application, among which 6.7.12 mentions: "The decorative layer of the building exterior wall should use materials with Class A combustion performance, but when the building height is not more than 50m, Class B1 materials can be used." Therefore, when the building height is greater than or equal to 50m, Class A non combustible materials must be used for the building exterior wall.

01.Material Overview

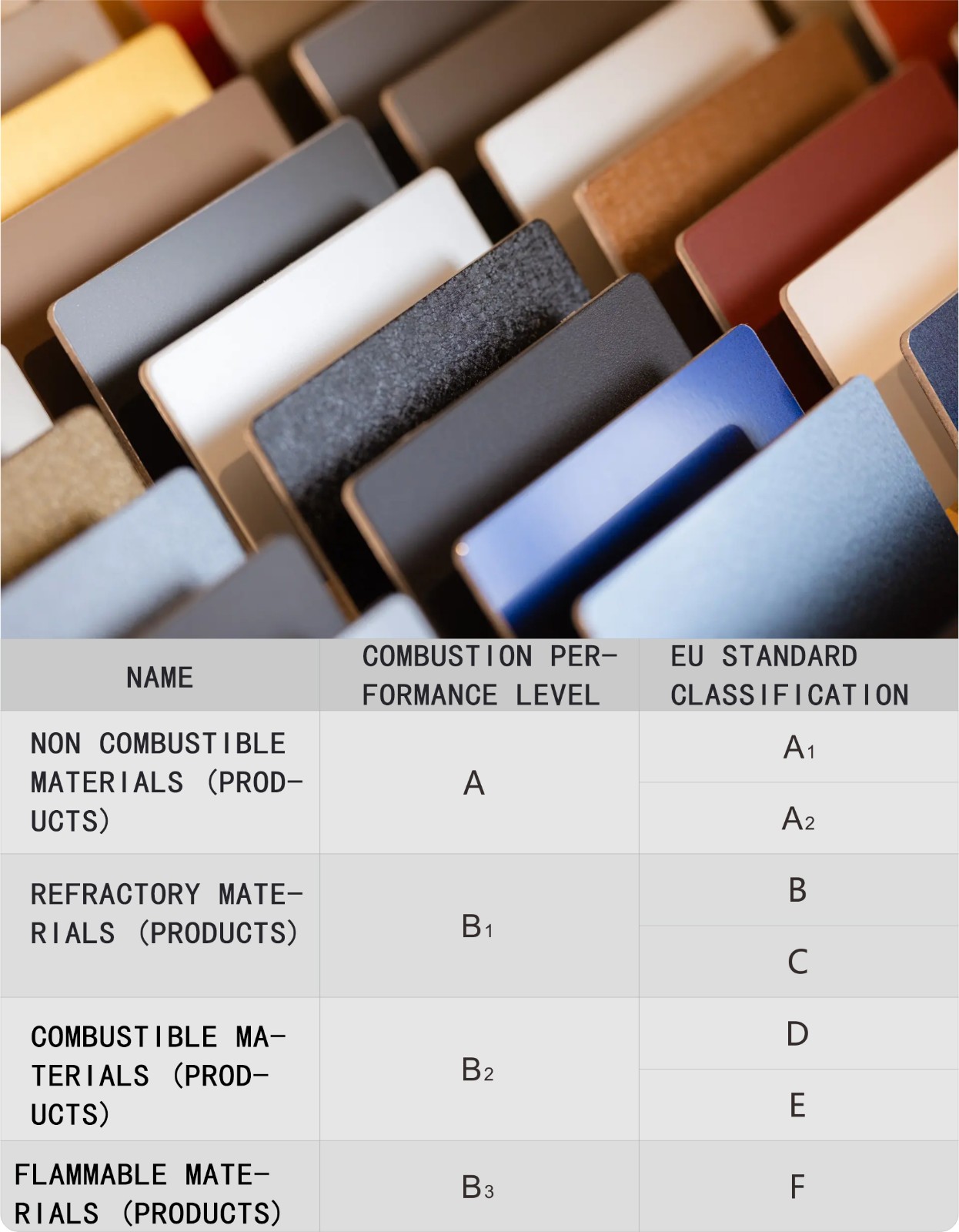

GB 8624-2012 Classification of Combustion Performance of Building Materials and Products and EU Standard EN 13501-1:2007 © Vihardoo7

Aluminum Composite Panel (ACP), also known as Aluminum Composite Material (ACM), is a Class A fire-resistant aluminum composite panel formed by hot extrusion processing of two layers of decorative and protective cloud coated aluminum alloy panels and intermediate mineral fillers on dedicated production equipment.

A-grade fire-resistant aluminum composite panels abandon the traditional halogen-free flame-retardant modified polyethylene material and replace pure low-density polyethylene as the core material. They use an inorganic mixture composed of raw materials such as calcium carbonate, silica micro powder, quartz sand, perlite, polypropylene short fibers, aluminum hydroxide, zinc molybdate, acrylic adhesive, etc. as the core material. The product performance meets the A-level fire-resistant requirements in the standard and can be applied to exterior wall decoration projects such as building curtain walls without being limited by building height.

A-grade fireproof aluminum composite panel product structure © Vihard

The standard thickness of A-grade fire-resistant aluminum composite panel used for building curtain walls is 4mm, with 0.5mm aluminum alloy panels on the front and back, and a 3mm thick core material in the middle. The surface of aluminum alloy is coated with decorative and protective fluorocarbon resin, and currently the fluorocarbon pre roll coating baking paint process is widely used. Widely used in building decoration fields such as exterior walls, renovation of old buildings, interior walls, and ceilings.

02. Material properties and characteristics

Aluminum composite plate groove casting processing © Tal Friedman

A-grade fireproof aluminum composite panel, as a new type of building decoration material, not only has excellent fire resistance, but also unparalleled flatness, versatile surface treatment ability, excellent processing performance, and convenient construction method.

·Super peel strength

Aluminum composite panels have adopted a new process, which has improved the most critical technical indicator of "peel strength" to an excellent state, resulting in corresponding improvements in the flatness and weather resistance of aluminum composite panels.

·Lightweight and high-strength

According to relevant testing data, the steel degree of 4mm thick aluminum composite plate can reach 2400kNcm2/m, while the thickness of aluminum veneer needs to be at least 3.3mm to achieve this steel degree, but it is heavier than aluminum composite plate.

KVARTERET STENEN Apartment © White Arkitekter

·Ultra durability

Due to the use of fluorocarbon pre roll coating paint process, it has unique advantages in terms of weather resistance. Whether in hot sunlight or cold wind and snow, it does not damage the beautiful appearance and can maintain a long-lasting skin effect.

·Diverse surface colors

The application of pre roll coating and baking paint technology can provide a variety of surface color treatments, including classic metal color series, fantasy color series, as well as imitation of stainless steel, copper, stone, wood grain, concrete and other effects, with a large space for personalized selection.

·Excellent fire resistance performance

The middle is a non combustible mineral polymer core material, and the two sides are extremely difficult to burn aluminum layers. The fire resistance of the material can meet the requirements of Class A, making it a safe and non combustible material that complies with the fire protection regulations for high-rise buildings.

KVARTERET STENEN Apartment © White Arkitekter

·Good processing performance

Aluminum composite panels can be cut, trimmed, slotted, sawed, punched, processed with countersunk heads, as well as cold bent, cold folded, cold rolled, riveted, screw connected, or glued together. They have good processing performance and can be bent into various shapes such as arcs and right angles. They can cooperate with designers to make various shape changes.

· Easy to maintain and upkeep

Architectural tomb walls generally require maintenance and cleaning after a few years of use. Aluminum composite panels, due to their resistance to pollution and good cleanliness, only require neutral cleaning agents and clean water. After cleaning, the panels will look brand new.

03.Material classification

There are many varieties of aluminum composite panels, and they are a new type of material, so there is currently no unified classification method. They are usually classified according to their use, product function, and surface decorative effect.

· Classified by purpose

According to their use, aluminum composite panels can be divided into aluminum composite panels for building curtain walls, advertising decoration, and indoor use. This article focuses on aluminum composite panels for building curtain walls, which have higher performance and standard requirements than aluminum composite panels for exterior wall decoration and advertising, and indoor use.

Aluminum composite panels for building curtain walls © Henke AG

·Classified by Function

According to their functions, they can be divided into fire-resistant aluminum composite panels, antibacterial and anti-virus aluminum composite panels, anti-static aluminum composite panels, etc. The combustion performance of fireproof board aluminum composite board products reaches the flame-retardant level (B1 level) or non combustible level (A level); Antibacterial and aluminum resistant composite panels have the function of controlling microbial activity and ultimately killing bacteria; The surface resistivity of anti-static aluminum composite board is below 109Q, so it is not easy to generate static electricity, and dust in the air is not easy to adhere to its surface.

· Classified by surface decoration effect

According to the surface decoration effect, it can be divided into standard color series, gold color series, fantasy color series, pure still color series, and earth color series; Imitation stainless steel wire drawing. Imitation of copper, imitation of titanium zinc, imitation of wood grain, imitation of stone, imitation of concrete, mirror aluminum composite panels, etc. Some manufacturers with research and development capabilities also periodically release decorative effects with innovative culture.

04.Installation process

Dry hanging construction technology for aluminum composite panels © Henke AG

Aluminum composite panels usually use dry hanging construction technology, which is easy and fast to install. In the early days, adhesive sealed systems were mostly used for installation. Currently, open curtain wall installation systems are mostly used.

Compared to traditional sealed curtain walls with adhesive seams, open tomb walls are more in line with building energy efficiency requirements, extend building lifespan, and reduce overall construction and maintenance costs for building exterior walls.

05.Application case of A-grade fireproof aluminum composite panel

Qujiang Sports Center © Aedas

The Qujiang Sports Center, the first large-scale Grade A comprehensive sports venue in northwest China with the theme of "Electric Sports", integrating ball sports, cultural performances, and electronic sports, as well as the Qujiang Esports Industrial Park where it is located, were conceptually designed by Aedas Executive Director Hu Qingfeng and his team. Located in the central area of Qujiang New District with the Big Wild Goose Pagoda as its core, it will be an important pivot for Xi'an to build the "Silk Road Esports Capital" and create an "ecological" industrial cluster for electric sports.

The venue design is based on the concept of "hibiscus petals", outlining a smooth and rounded main arena through soft, dynamic and varied curves. The facade is wrapped and unfolded with A-level fireproof aluminum composite panels with iridescent pearl white effect as the main material, creating a highly technological and futuristic double curved irregular tomb wall, like a blooming Guanrong, presenting a prosperous Tang style. It complements the characteristics of the electronic sports industry and the modern vitality of the Qujiang New Area.

Shanghai Mango Plaza Photography: Zhang Qianxi

The Shanghai Mango Plaza, designed by Benoy for overall planning, architectural design, and interior design, features decorative lines composed of three design languages: vertical lines, horizontal lines, and intersecting horizontal and vertical lines. The soft and twisted decorative lines have a geometric texture from any angle, and different volumes and facade forms are distinguished by frameless glass strips for easy identification.

The exterior wall lines of the building glass box are achieved through the folded lines of the wall rod strands, and its material is processed into three-dimensional folded decorative lines using A-grade fireproof aluminum composite materials. These three-dimensional folded lines and folds create a rhythmic and dynamic facade effect, while the unique metallic luster of aluminum composite panels shines together on the facade.

Tianjin University of Science and Technology Affiliated Middle School © courtesy of 3A

The junior high school campus of Tianjin University of Science and Technology Affiliated Middle School, located in the Tianjin Zhongxin Ecological City, has a total construction area of about 25000 square meters. The campus is not only a public place, but also requires high-level safety protection to protect children, and A-level fireproof materials are not an option.

The overall shape of the building is in the shape of a "back", facing the construction of the ecological valley, to maximize the satisfaction of sunlight demand. The building facade adopts over 6000 square meters of non combustible grade aluminum composite material, and uses perforation technology to finely carve out the contours of several lush trees, which complement the ecological valley.

Erie Basin DUET Apartment © John Kees

Erie Basin Duet Apartment, located on Salford Wharf in the northernmost part of Manchester, has two 15 storey residential buildings towering like a pair of ballet dancers. Their slender backs are connected together, extending in a fan-shaped manner towards the water surface, and are known as the 'duet'.

The building facade is made of glass and A-grade fire-resistant aluminum composite materials, distributed in a folded angle shape, just like the positions of the two buildings themselves echo each other. Aluminum composite materials are composed of three shades of red copper, which emit different luster through matrix arrangement. It is like a naturally aged brick with different colors, which also echoes the red and brown urban color of Manchester.

Sue&Tie Residential Building © Beat Biihler

SUE&TIL apartments have become the largest wooden residential buildings in Switzerland, consisting of 20 6-story buildings. The basement, ground floor, stairs, and core of the building are constructed with concrete, while the rest of the floors and exterior walls are made of wood. The facade cleverly adds vitality to the building by using high rise windows.

The facade cladding is made of A-grade fire-resistant aluminum composite material, and the silver metal facade contrasts sharply with the black window contours and exposed concrete semi public passage areas. The square shape and regular bay window sills are also pleasing to the eye in the simple horizontal and vertical cutting presentation.

Grow Hotel © Rasmus Hjortshøj

The Grow Hotel designed by 3XN Architects is a Nordic style hotel located in Stockholm, the capital of Sweden. The exterior of the building is in a herringbone shape, with two wings opening outward, creating a welcoming posture. The soft V-shaped facade covered with aluminum composite material gives it a clean, bright, exquisite and peaceful appearance, forming a sharp contrast with the blue glass curtain wall and the green plants in the park.

The architect drew inspiration from the metal exterior walls of neighboring industrial buildings for the building's appearance, and the design of its anodized aluminum composite panel fa ç ade aims to reduce the size of the blue giant curtain and other more monolithic buildings nearby. The silver non combustible aluminum composite folding facade challenges the power of nature like an iceberg, transforming simple and minimalist design into a delightful, comfortable, and subtle sense of luxury.

French Riverbank Building © Sergio Grazia

The exterior of the French Riverbank Building is made of A-grade fire-resistant aluminum composite panels with anodized texture and mirror effect, and the continuous V-shaped diamond mirror scales have attracted much attention for their three-dimensional appearance. Aluminum composite materials are lightweight and easy to form, so they can be creatively processed to transform flat panels into various architectural shapes, which is also a key factor favored by architects.

The aluminum exterior is the core of the entire architectural design, with a prism like surface gradually rising from the ground, giving the entire building a pure aesthetic. In order to achieve the design effect, the upper and lower edges of the lintel board of the window frame are wrapped in mirror aluminum composite material, making the entire building have a continuous reflective exterior.