Aluminum Fangtong, due to its unique appearance, occupies an irreplaceable position in the industry and has become a unique representative of decorative materials in the construction industry. Aluminum square ducts are commonly used in indoor spaces such as suspended ceilings and partitions. So, how should aluminum square ducts be constructed at the exterior facade position?

Today, let's talk about the aluminum square on the exterior facade from the following aspects:

1. What is the aluminum square on the exterior facade?

2. Construction technology of aluminum square tube on the exterior facade.

01.What is the aluminum square on the exterior facade

1、Concept

Aluminum square tube is a commonly used aluminum product in building decoration materials. The aluminum square tube on the exterior is made by processing aluminum materials with stronger performance such as product hardness and straightness.

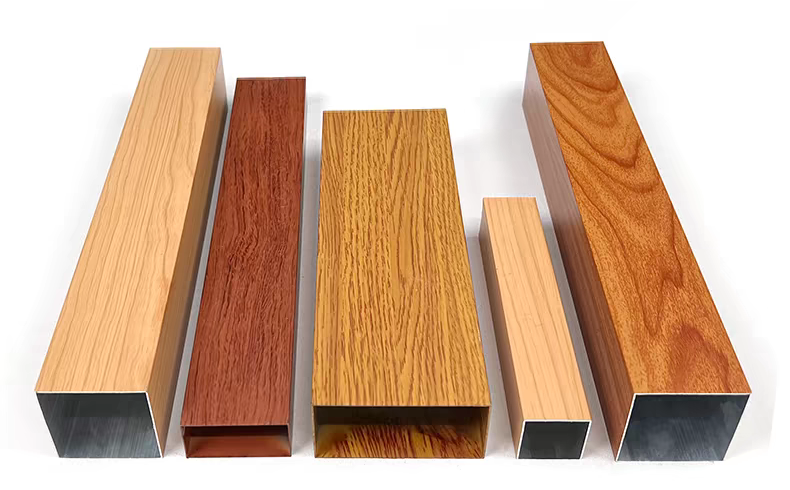

▲Example of Materials (Part)

▲Example of Effect

2、Characteristic

a、Lightweight material, convenient installation, environmentally friendly and sustainable;

b、Diversified exterior design;

c、Corrosion resistance, aging resistance, strong mechanical performance, good ventilation and heat insulation performance;

d、Easy to maintain, with a wide range of applications.

3、Type

a、Classification based on different surface treatment processes

It can be mainly divided into fluorocarbon paint, polyvinyl chloride paint wood grain heat transfer printing, powder, stone grain, real stone paint, anodizing, etc.

b、Classification based on different shapes of aluminum square tubes

It can be mainly divided into straight bars, arcs, irregular shapes, etc.

4、Common parameters

The common parameters for aluminum square joints on exterior walls are usually as follows:

The specifications of aluminum square tube include bottom width, side height, thickness, and length.

Bottom width: 30mm~200mm, with a width difference of 5mm for each height.

Side height: 20mm~200mm, with a height difference of 5mm between each larger height.

Thickness: 0.8mm~4.0mm.

Length: Typically, a length of 1-3m is recommended, and can be customized for lengths up to 6m.

Colors are usually divided into solid colors, imitation wood grain, pattern transfer printing, etc., and can also be professionally customized.

(The above are commonly used parameters for most product materials on the market, for reference only)

02.Construction process of aluminum square joints on exterior walls

The construction process of the external wall aluminum square tube is not very complex, and is generally similar to ordinary dry hanging curtain walls. Let's take the most common external wall aluminum square tube construction process as an example and take a look at its specific construction process together!

The main processes are:

Artillery preparation一fixing keel一 installing aluminum square joint一sealing treatment一 decoration treatment一acceptance inspection

1、Construction preparation

According to the design drawings or actual on-site conditions, measure the installation dimensions of the external wall aluminum square joint, including length, width, height, etc. Determine the required quantity and specifications of aluminum square joints for external walls based on measurement dimensions.

At the same time, prepare construction tools, conduct wall base inspection, provide personnel training, and check whether the construction environment meets the construction conditions.

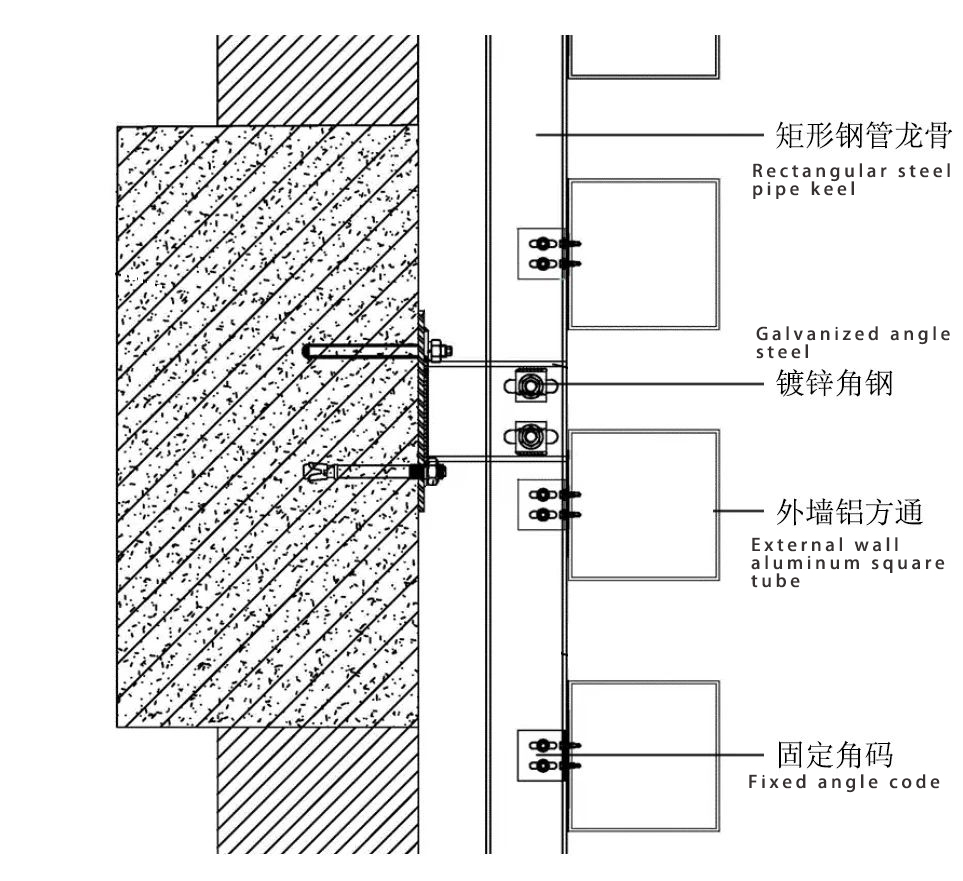

2、Fixed keel

According to the design requirements, steel keel is installed on the exterior wall, usually fixed to the load-bearing wall using screws and accessories to ensure the stability and flatness of the keel.

3、Installing aluminum square tube

Place the pre prepared aluminum square tube on the keel and adjust it according to design and size requirements to ensure even and beautiful gaps between the square tubes. Use screws and corner codes to secure the aluminum square to the keel, paying attention to the position and quantity of screws to ensure secure fixation.

4、Sealing treatment

During installation, if it is necessary to connect multiple aluminum square tubes, screws and connectors can be used for connection, and then weather resistant sealant or foam sealant can be used for sealing.

5、Modification processing

As needed, modify the edges of the aluminum square tube by chamfering, coating, etc. to make it more aesthetically pleasing.

6、Cleaning and organizing

After installation, clean and organize the construction site to remove debris and garbage.

7、Precautions

Before construction, it is necessary to conduct a visual inspection of the installed exterior wall aluminum square to ensure that there are no obvious deformations, damages, or color differences in the appearance.

Use measuring tools to perform size testing on the installed aluminum square joints on the exterior wall, ensuring that the dimensions meet the design requirements.

After installation, the fixed aluminum square should be inspected to ensure that the fixing screws are securely fastened and there is no looseness.

Finally, a comprehensive evaluation of the installation process and construction quality should be conducted to ensure that the installation of the external wall aluminum square tube meets the design requirements and relevant standards.

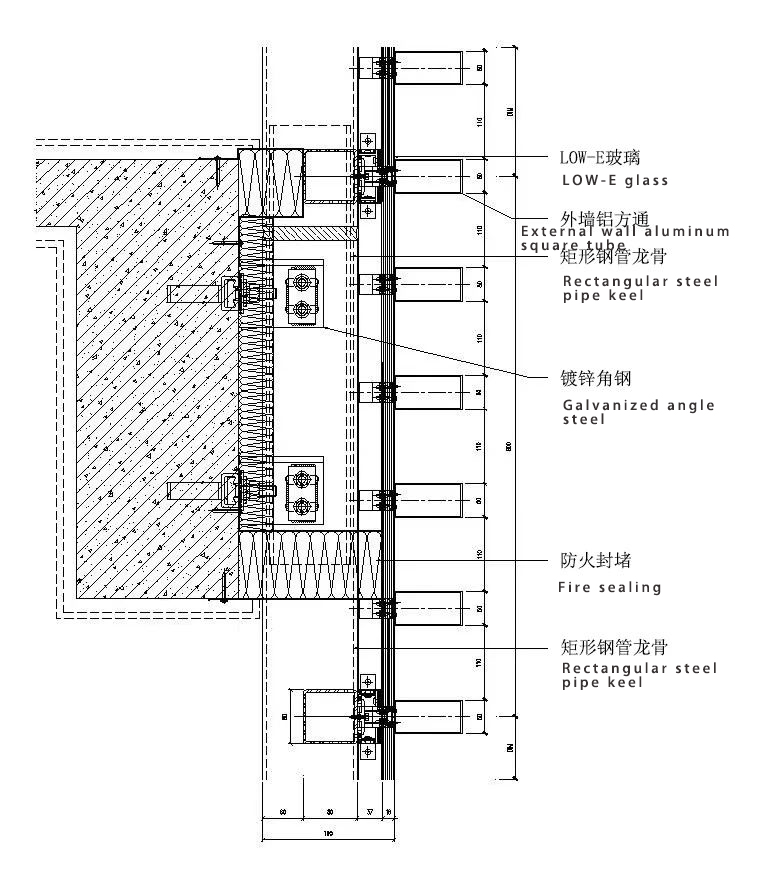

8、Process nodes

▲Process node construction