In recent years, aluminum panels have been widely used in architecture and landscape design, ranging from building facades to a dividing strip of landscape walls. When metal decoration is needed, aluminum panels may be used.

Today, let's take a look at the application design of aluminum plates in the demonstration area.

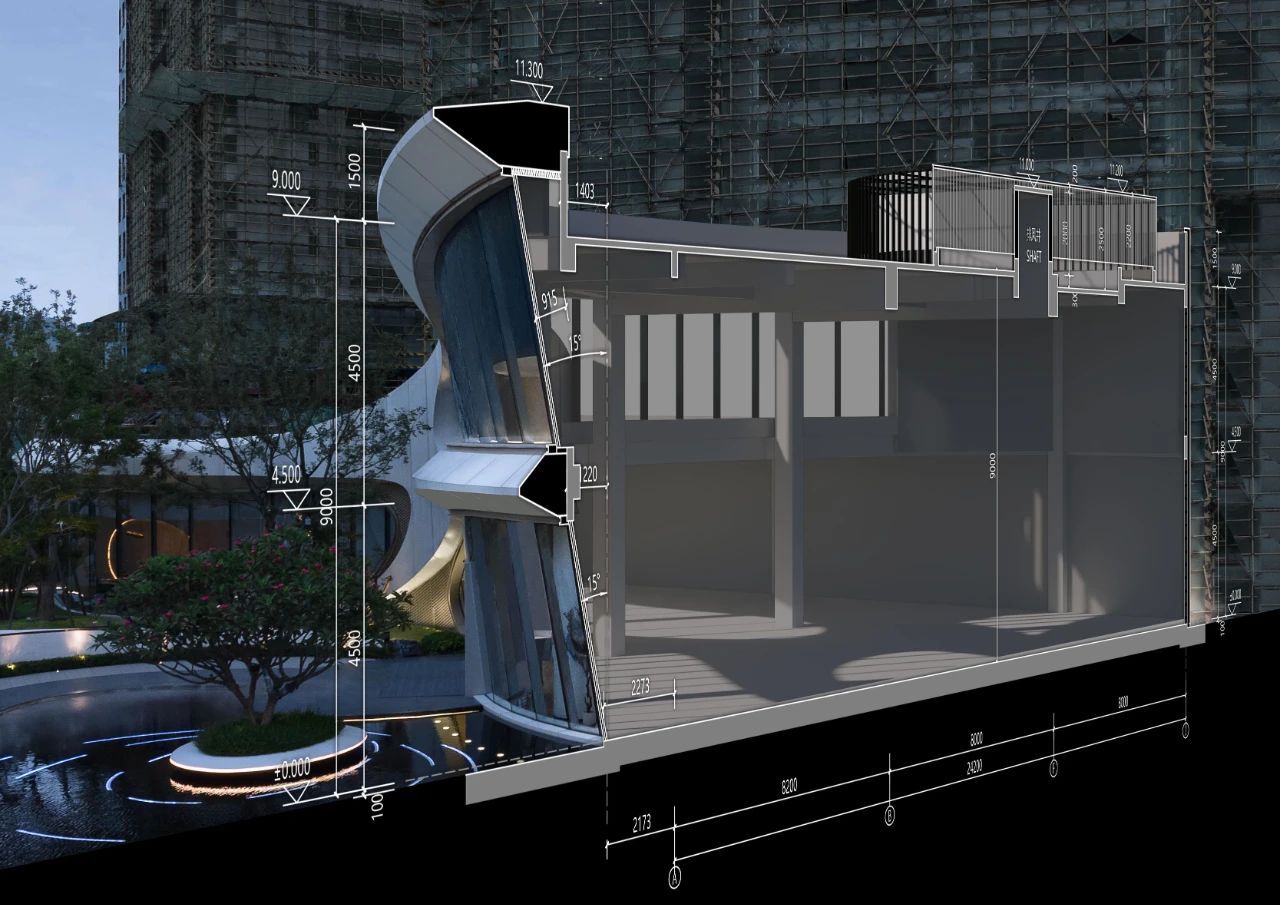

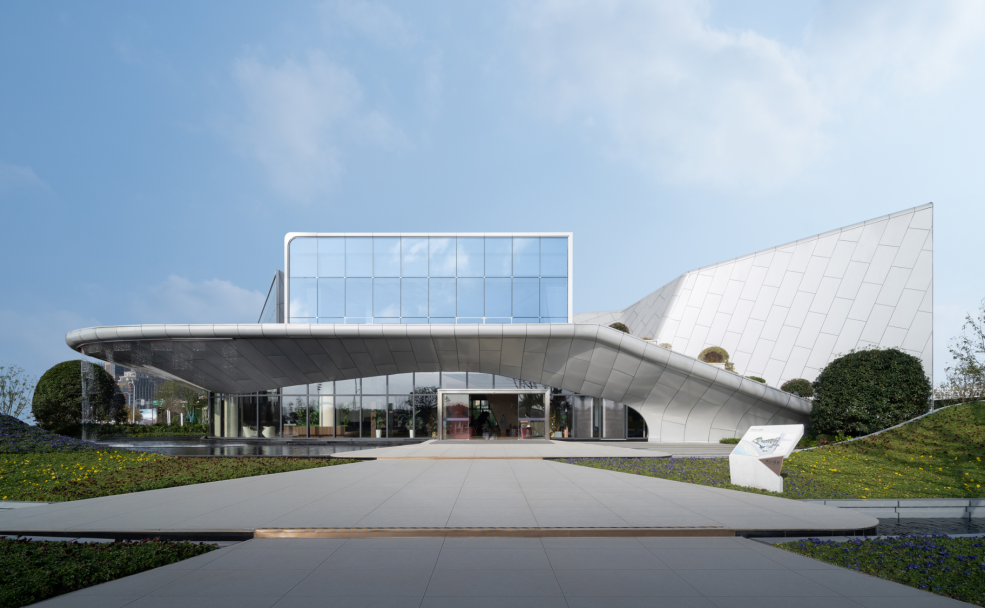

▲Realistic Map of Demonstration Zone

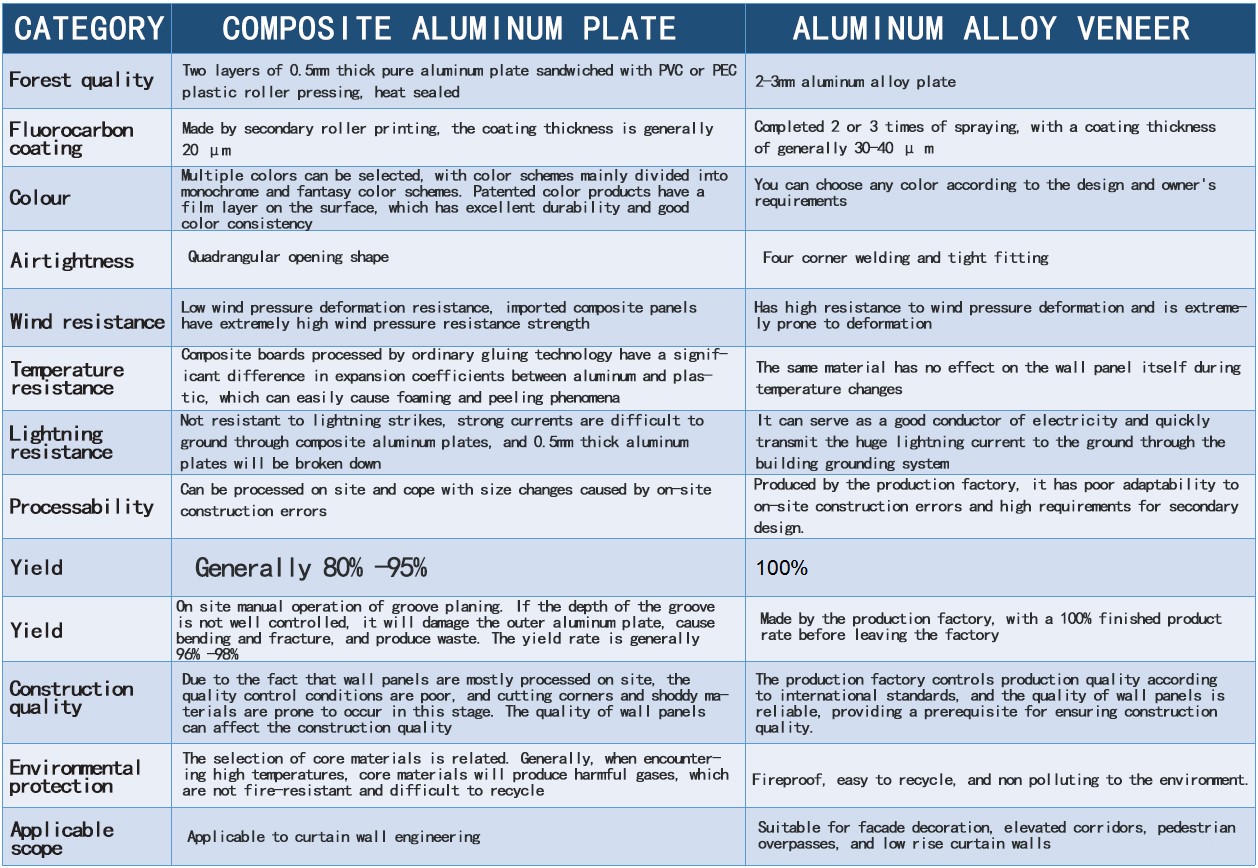

In terms of classification, aluminum panels used for building decoration are mainly divided into two types: "aluminum single panel" and "composite panel":

▲Comparison diagram (source network)

Aluminum veneer refers to a new type of building decoration material formed by using aluminum alloy sheet as the substrate, undergoing chrome treatment, and then CNC bending and other technologies, and using fluorocarbon or powder coating technology. Perforated aluminum panels, imitation stone aluminum panels, wood grain transfer aluminum panels, mirror aluminum panels, and so on, which are commonly referred to, belong to this category of aluminum panels.

Aluminum composite board is a general term, mainly referring to the use of various complex processing methods to composite chemically treated coated aluminum sheets (aluminum veneers) as surface materials on suitable base materials, ultimately forming aluminum composite boards. According to the different composite base materials, aluminum composite panels have different material characteristics. Common examples include aluminum-plastic panels, honeycomb aluminum panels, etc.

Let's take a closer look at common types.

1

Perforated aluminum plate

First, let's take a look at perforated aluminum panels in aluminum veneers.

Perforated aluminum plate refers to a rectangular material with a uniform thickness and a cross-section obtained by pressure processing (shearing or sawing) using pure aluminum or aluminum alloy materials. It is actually a perforated metal aluminum plate, also known as perforated aluminum plate, perforated gold plate, or perforated screen.

▲Realistic environment © Literal translation of architecture: He Lian

Compared with other metal materials, perforated aluminum panels have a smooth surface and advantages such as high temperature resistance, corrosion resistance, fire resistance, moisture-proof, shockproof, lightweight and concealed structure, good physical environment of buildings, broad vision, and beautiful appearance. They are a new material that reduces noise and also has decorative effects

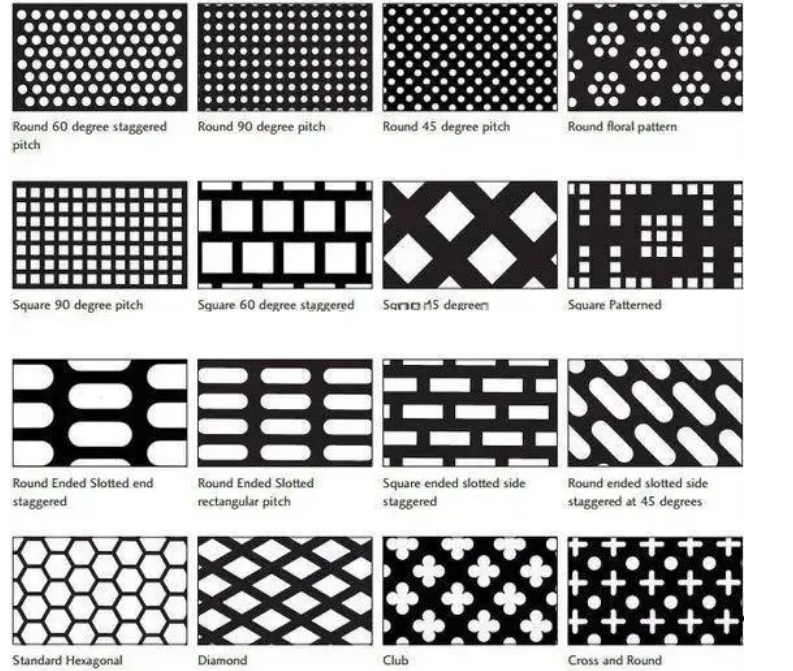

Middle holes mainly include rectangular holes, square holes, diamond holes, round holes, long round holes, hexagonal holes, cross holes, triangular holes, long waist holes, plum blossom holes, fish scale holes, pattern holes, octagonal nets, herringbone holes, pentagonal star shaped holes, irregular holes, bulging holes, irregular holes, louver holes, etc.

▲Opening style

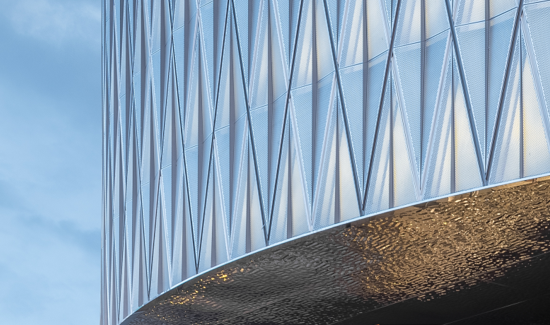

The circular curved roof of Taizhou Longhu Yuhu No.1 exudes a strong sense of tension, creating a project that is both indicative and unique. Combined with the three-dimensional perforated aluminum plate that emits light from the facade, it refracts the city's lights and peels off amidst the hustle and bustle, allowing for a sense of heaven and earth.

The second floor of the building is composed of 776 10mm perforated panels, and the curved facade presents a folded and withered texture, inspired by the constantly changing reflection of the water surface. The combination of triangular perforated plates originated from diamonds.

▲Realistic view of Longhu Yuhu No.1 in Taizhou

At night, the facade is illuminated by internal light sources, and the undulating folds on the exterior walls are further highlighted, giving the building a strong sculptural feel.

▲Realistic view of Longhu Yuhu No.1 in Taizhou

The facade of Chengfa Tianyue Bay extracts the streamlined elements of the winding sand creek on the north side of the plot, incorporating inspiration from the interweaving of flowing light, and using flowing lines as the main framework of the display area.

▲Detailed sample

Using silver white aluminum panels and champagne gold perforated aluminum panels to simulate the agile curve lines of butterflies spreading their wings, the shadow layers of the building's lines are strengthened, giving a fashionable visual impact of "gilding and silver plating" and an air of transcendence, reflecting the customer's noble identity.

Presenting a relaxed and powerful space through high-quality aluminum plate walls.

▲Detailed sample

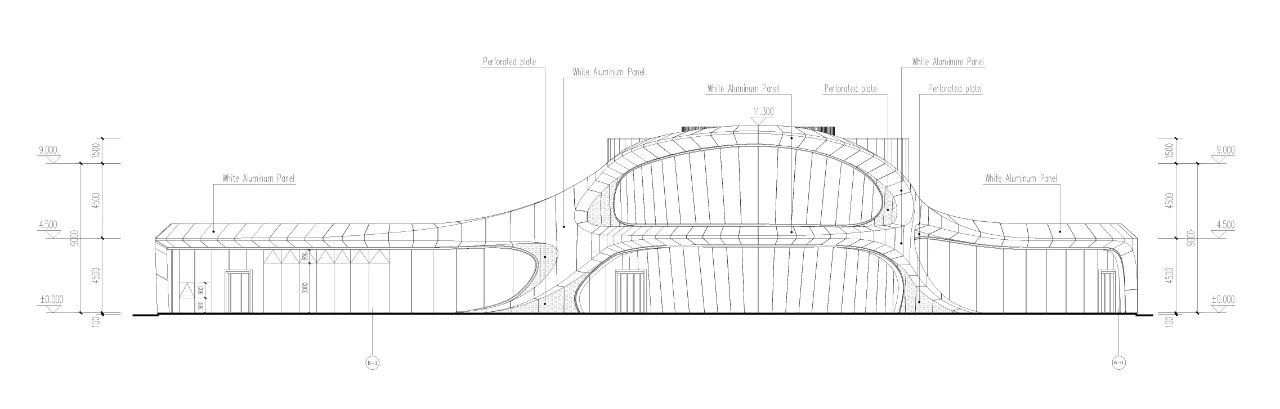

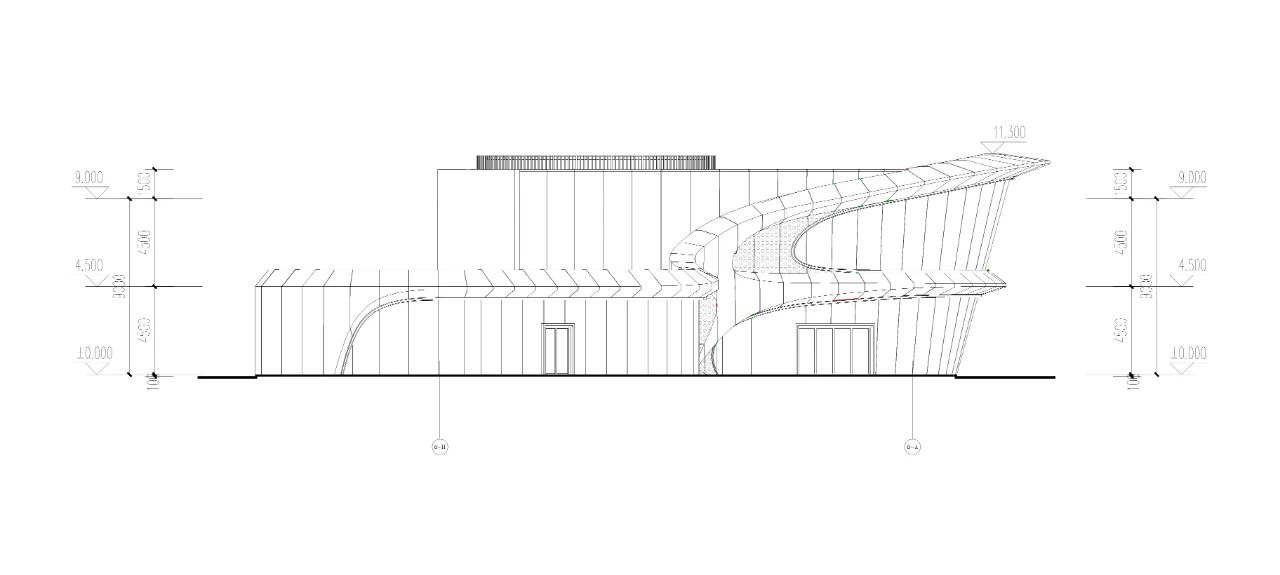

▲Display Area Facade

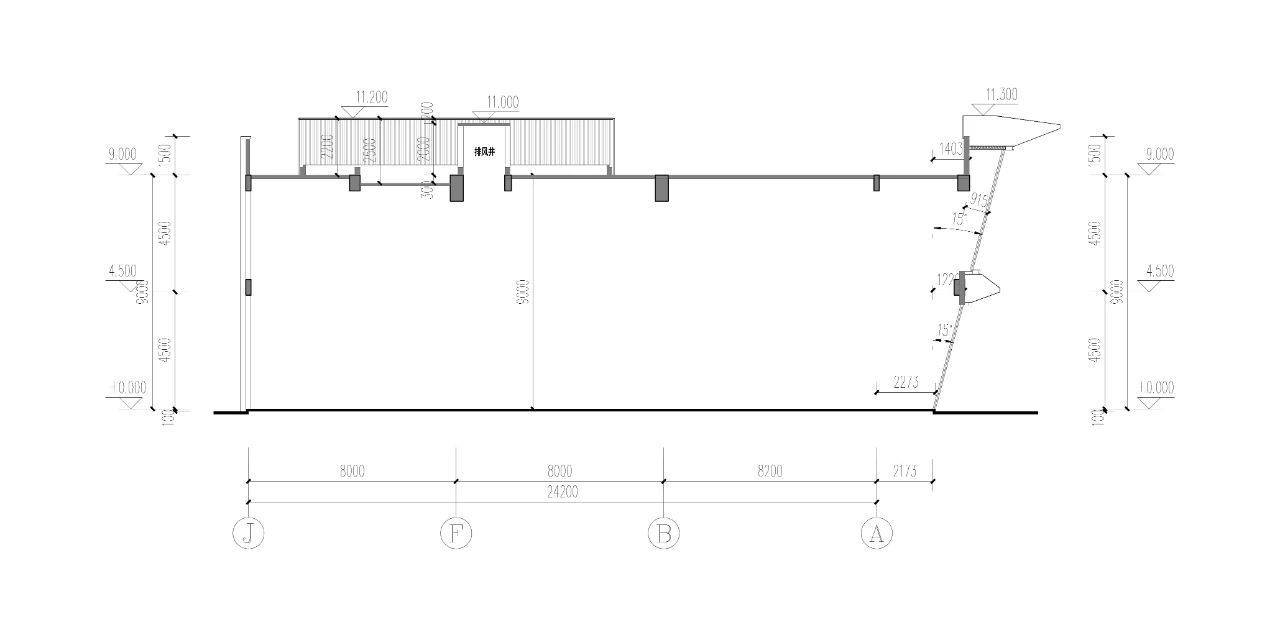

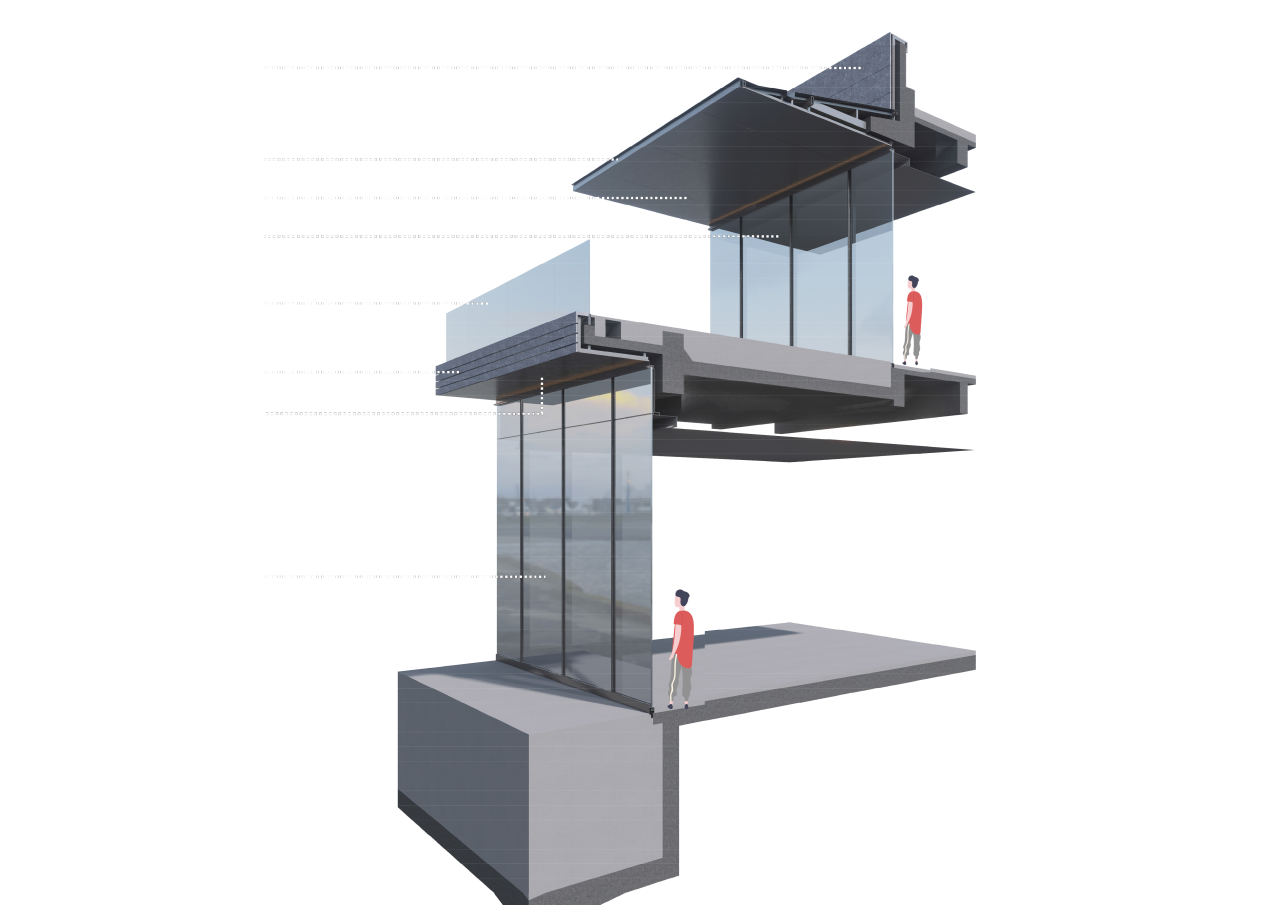

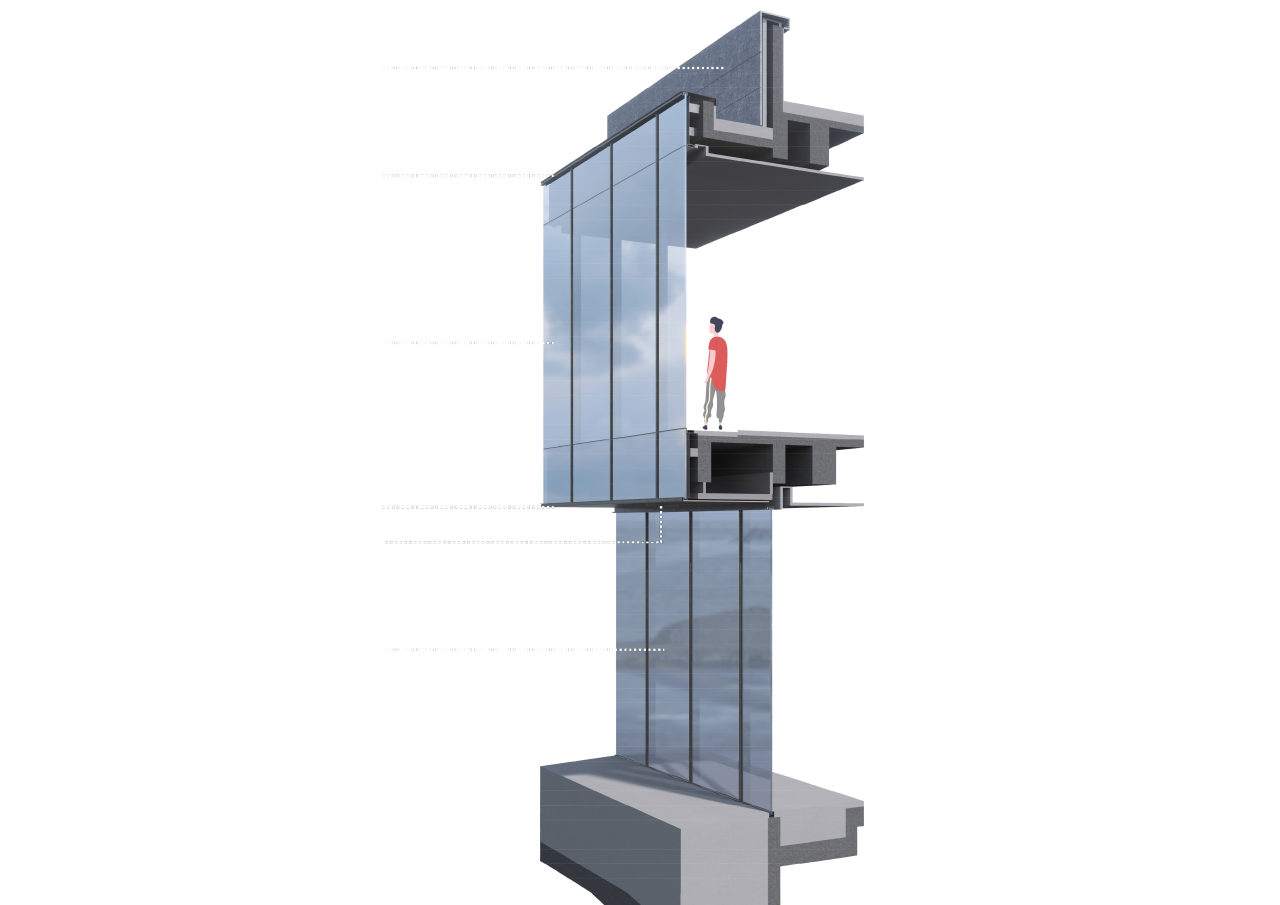

▲Display Area Section

2

Imitation stone aluminum plate

The appearance of imitation stone aluminum panels compensates for the shortcomings of traditional natural stone itself, and can achieve the decorative effect of real stone without consuming resources, gradually becoming a highly sought after choice.

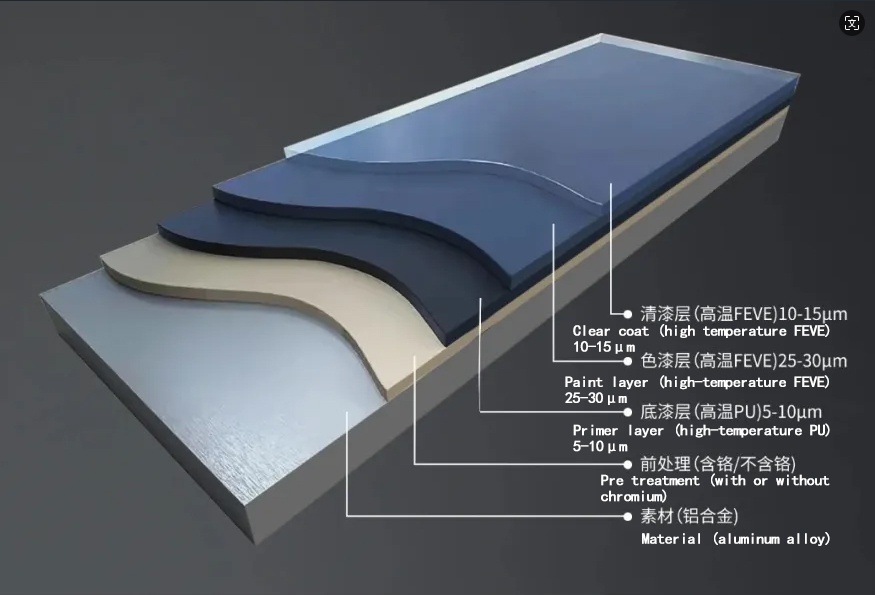

Imitation stone aluminum panel is a material that uses aluminum veneer as the base, replicates the texture, texture, and color of natural stone to mix and set, and then undergoes finishing treatments such as primer, topcoat, and gloss paint. Different colors of paint, patterns, etc. are cured at high temperature and attached to the surface of the aluminum veneer.

▲Source: google.cn Material composition diagram

Simply put, it means that the surface of aluminum veneer is subjected to a series of treatments to achieve the same effect and texture as natural stone, making it the most ideal substitute material for natural stone.

It has excellent physical properties such as environmental protection, energy conservation, waterproof and stain resistant, high flame retardancy, lightweight, fast construction, good value for money, strong plasticity, customizable colors, and long service life. It can withstand the invasion of environmental changes both indoors and outdoors.

▲source: google.cn

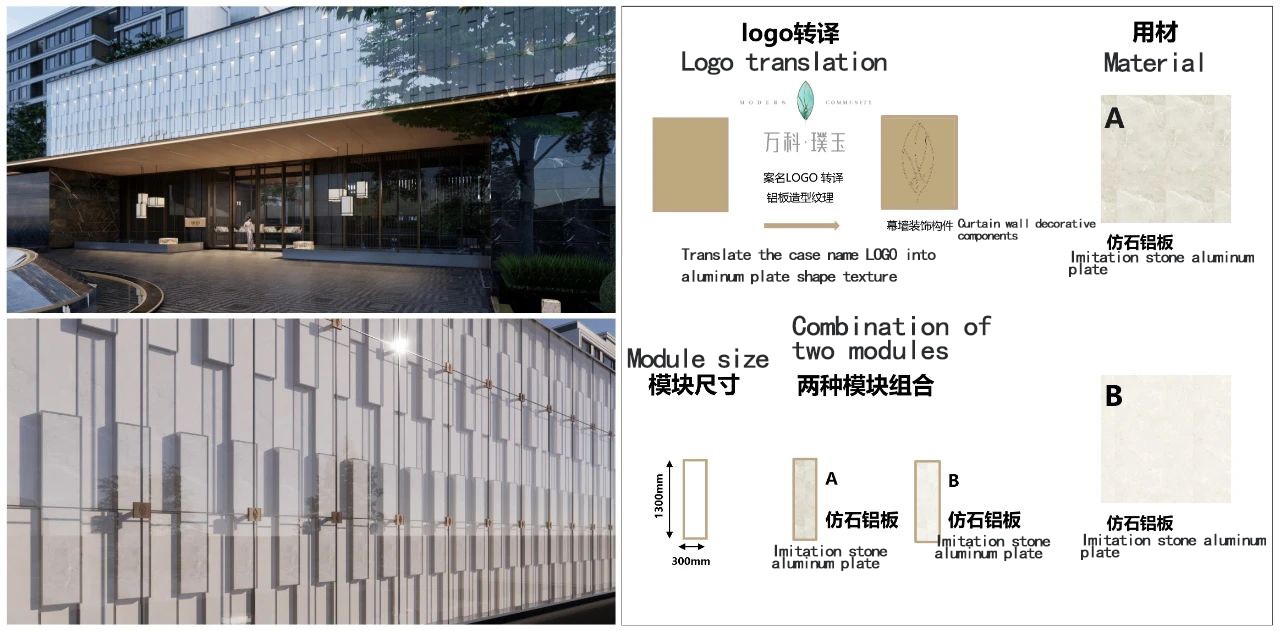

The facade curtain wall decorative components of Chongqing Vanke Puyuan Demonstration Zone are translated from the case name logo to aluminum plate texture. The overall geometric shape is based on the "jade seal" prototype, and two types of imitation stone aluminum plate module combinations are selected to accurately grasp their proportions and rhythm, creating a "light makeup appropriate" architectural aesthetics.

▲Chongqing Vanke · Puyuan Facade Realistic View

▲Chongqing Vanke · Puyuan Facade Realistic View

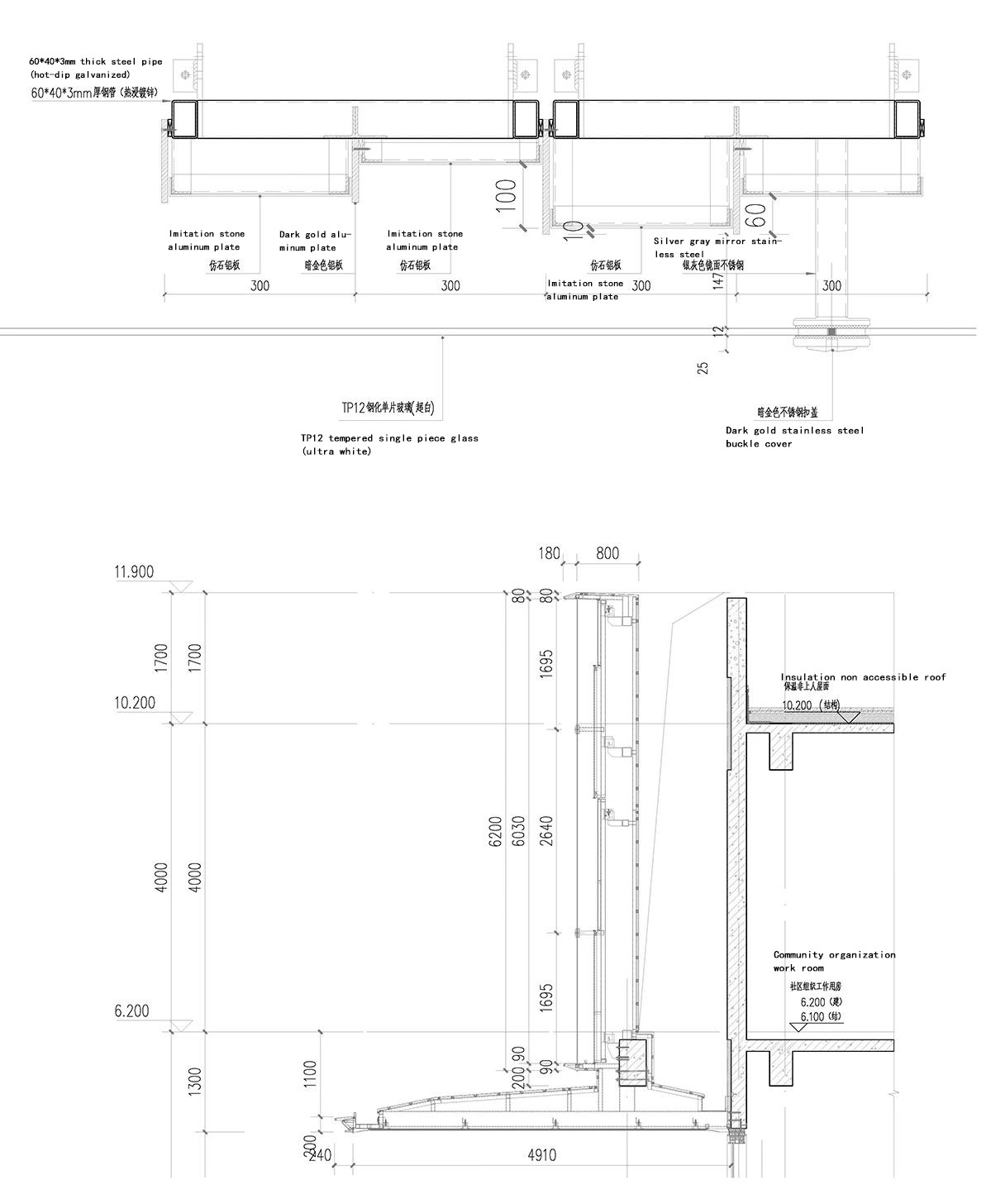

▲Building Facade - Curtain Wall Structure

▲Chongqing Vanke · Puyuan Facade Realistic View ©Chilshine

3

Imitation wood grain aluminum plate

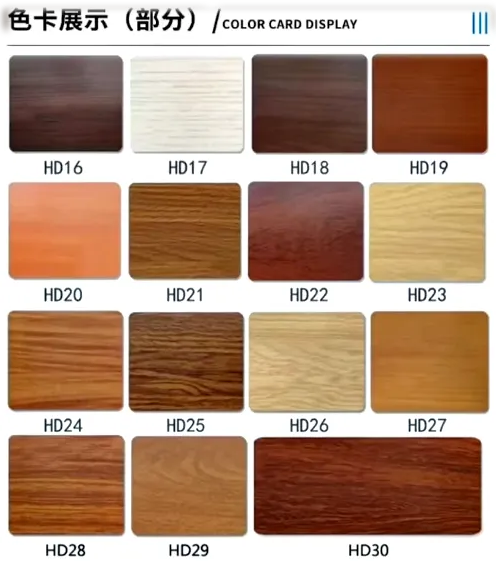

Imitation wood grain aluminum plate, also known as wood grain transfer printing aluminum plate, is a decorative material that uses high-grade aluminum alloy as the main material and presents the texture and color of wood on the aluminum plate through transfer printing technology.

It has the texture of wood, the characteristics of aluminum plate, and many advantages. Such as effect simulation, green environmental protection, lightweight, fire prevention, anti-corrosion, moisture-proof, capable of processing various geometric shapes, easy maintenance, long service life, etc. Therefore, imitation wood grain aluminum panels are considered an ideal substitute for wood in the construction and decoration industry.

▲Schematic diagram of color card for imitation wood grain aluminum plate (partial)

In recent years, it has developed rapidly and has been widely used in aluminum curtain walls, doors and windows, and home furnishings, becoming one of the new growth points in the aluminum profile industry.

In order to showcase modern Chinese aesthetics, Nanchang Poly Langyue not only focuses on the design of the fifth facade, but also pays attention to the creation of the sixth facade (outdoor ceiling) from a human visual angle.

▲Diffuse material brings soft lighting effects

The suspended ceiling in the central area of the gate hall comes from a certain ceiling in the Song Dynasty's Dageping area. After modern interpretation, the sharp lines of the large square combined with the concealed light strips are suspended in the form of corrugated wood grain aluminum panels and profiles with edges, fully showcasing the beauty of modern materials and craftsmanship.

The diatomaceous well sample was made with two materials, wood grain aluminum and champagne gold aluminum, and the bottom plate and buckle plate were freely matched. After light testing, the diffuse reflection wood grain aluminum plate was finally selected.

▲Realistic Picture of Nanchang Poly Langyue

▲Realistic Picture of Nanchang Poly Langyue

The design of the Five Ridge Hall and Four Slope Top on the facade of Hangzhou Jindi · Husong Danqing Mansion has created the architectural language of the Danqing Pavilion. The 2.6 meter overhanging sloping roof extracts ancient architectural elements such as overhanging eaves and paving, using wood grain boards combined with blue and black gold roof tiles. The light and shadow flow reflects the minimalism of national charm and the lightness of modern times.

▲Hangzhou Jindi · Husong Danqing Mansion

▲Fengming and Courtyard Guest Square in Deqing, Zhejiang

The warm and elegant imitation wood aluminum panels, deep and stable profiles, and warm and delicate blue eyed stones at the entrance of Fengming and Courtyard in Deqing, Zhejiang, remind people of the temperament and cultivation of the scholarly family in Jiangnan.

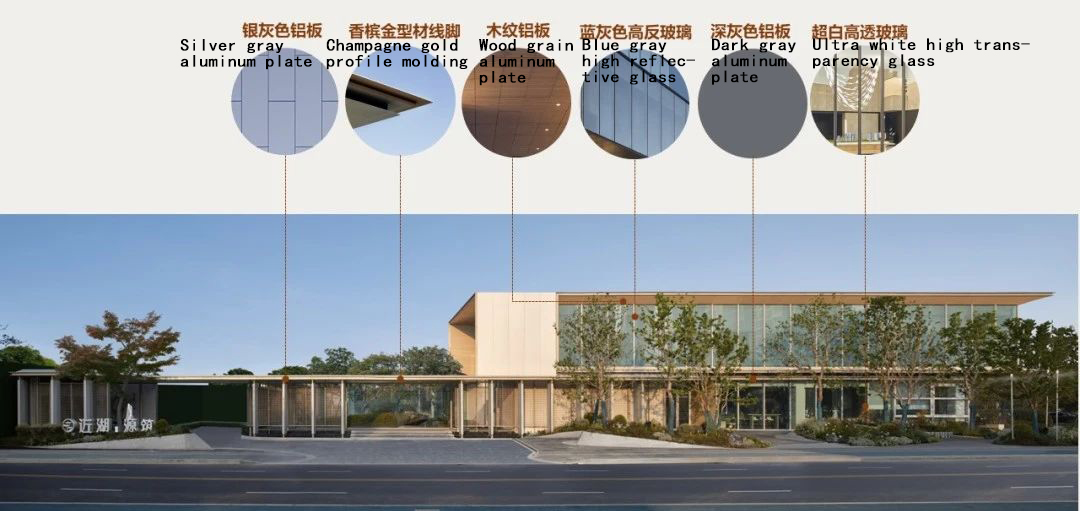

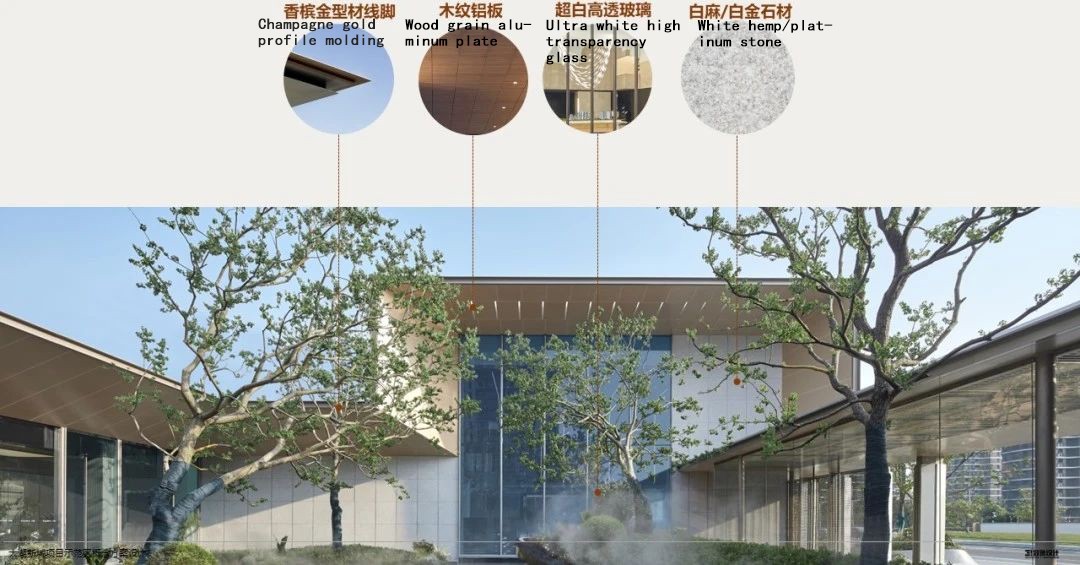

Let's take another look at the facade of Suzhou century Jinyuan "near the lake. The boundless ultra white glass brings the outdoor scenery into the interior infinitely. The light colored white gold stones and wood grain aluminum plates create a light and transparent building volume.

▲Real map of Suzhou century Jinyuan near the lake

Light and shadow design is the most unique stroke, combining different lines, materials, brightness and corresponding strokes to truly express the temperament of space.

▲Material schematic diagram

The geometric elements are interspersed and transformed, combining glass, stone, and metal aluminum panels. Each block uses different colors and textures to create a rich and clear atmosphere with a strong memory.

▲Realistic View of Suzhou Century Jinyuan Near Lake Source Architecture

▲Realistic View of Suzhou Century Jinyuan Near Lake Source Architecture

4

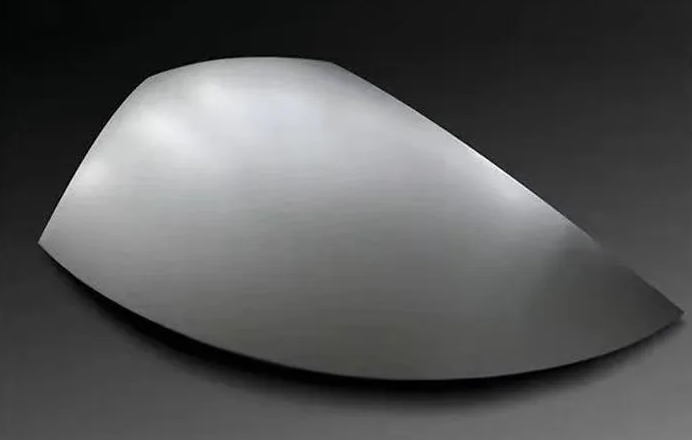

Double curved aluminum plate

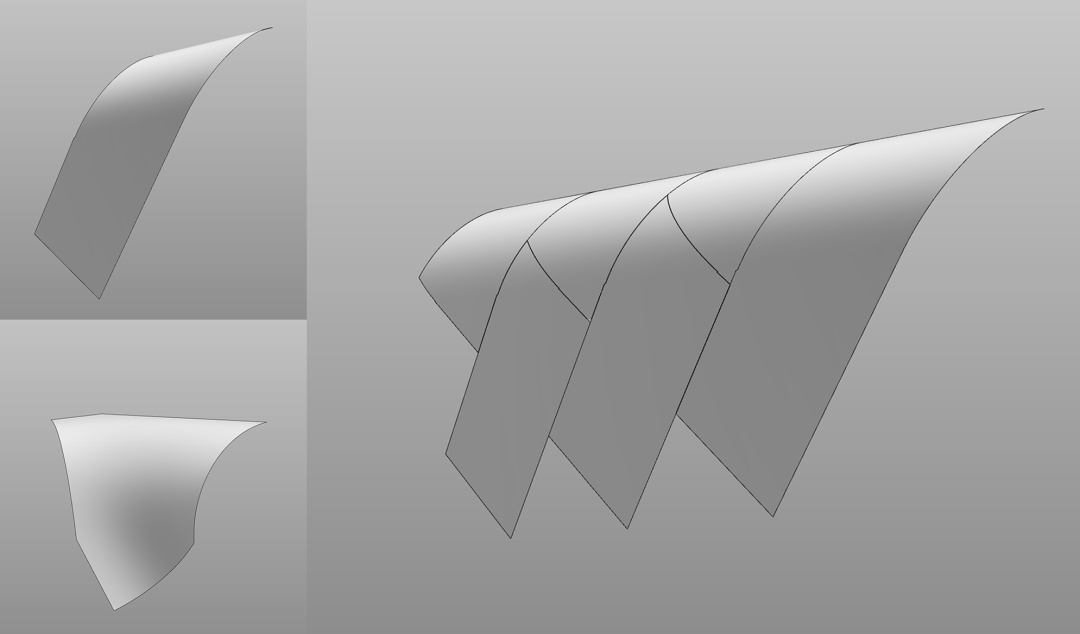

Double curved aluminum plate is a new type of building material. Its appearance is mainly designed with a hyperbolic shape, which has a very high decorative effect and aesthetic appeal.

▲Double curved aluminum plate

Double curved aluminum veneer, also known as curved aluminum veneer, is an aluminum veneer product with two curved surfaces, processed through multiple processes such as cutting, folding, bending, welding, reinforcement, polishing, and spraying based on two different arc curvatures using aluminum veneer as the substrate.

Firstly, this material possesses the unique and excellent performance of aluminum veneer itself, with light weight, good rigidity, dust and moisture prevention, fire and wear resistance, and long service life. Secondly, its shape is variable and can be designed and processed according to different curvatures, which can well meet the creative ideas of designers and give the building a good appearance decoration display effect. Furthermore, its structural design is humanized, easy to load and unload, and easy to install and construct. It is easy to maintain and replace, and has a strong modifiable shape.

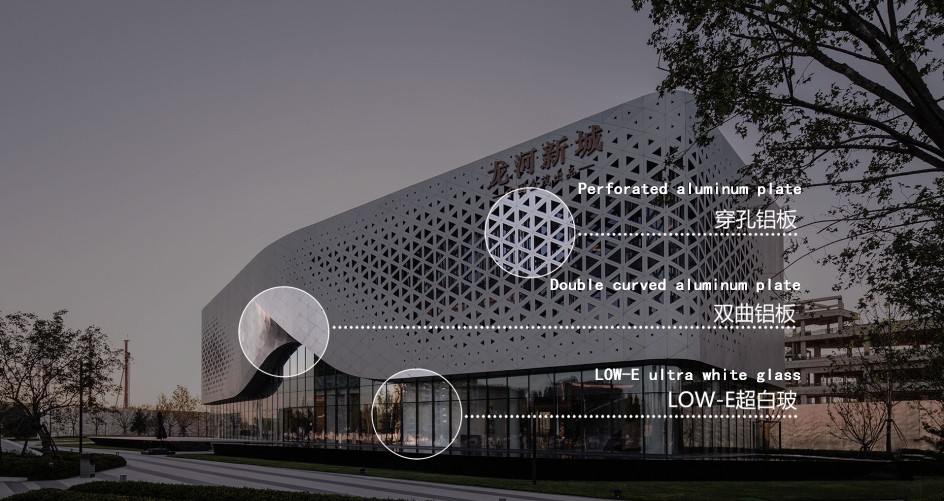

The exterior facade of the urban living room in Langfang Jinmao Longhe era is made of a combination of hyperbolic aluminum panels, perforated panels, and ultra-white glass on the ground floor, which not only highlights the sculptural and modern sense of the building, but also ensures the transparency of the line of sight and the interactivity with the landscape.

▲Langfang Jinmao Longhe Era Urban Living Room

▲Material schematic diagram

▲Langfang Jinmao Longhe Era Urban Living Room

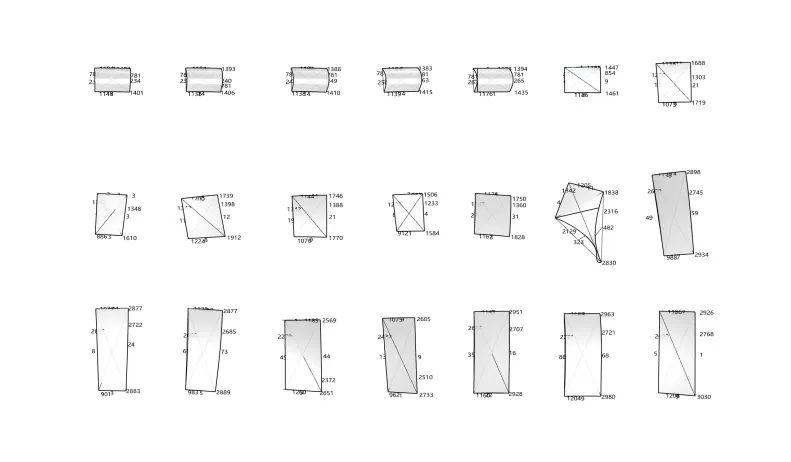

The pool water platform on the second floor of Ganzhou Jinrun Binjiang Yunchen Exhibition Center has been chamfered with a sense of craftsmanship. The aluminum plate has good toughness, and the design adjusts two-dimensional curves and three-dimensional surfaces to achieve good results. Each aluminum plate that forms a hyperbolic surface is different.

▲ Realistic view of Ganzhou Jinrun Binjiang Yunchen Exhibition Center

▲Dimensional diagram of hyperbolic aluminum plate

▲Analysis of aluminum plate shape

▲Realistic view of Ganzhou Jinrun Binjiang Yunchen Exhibition Center

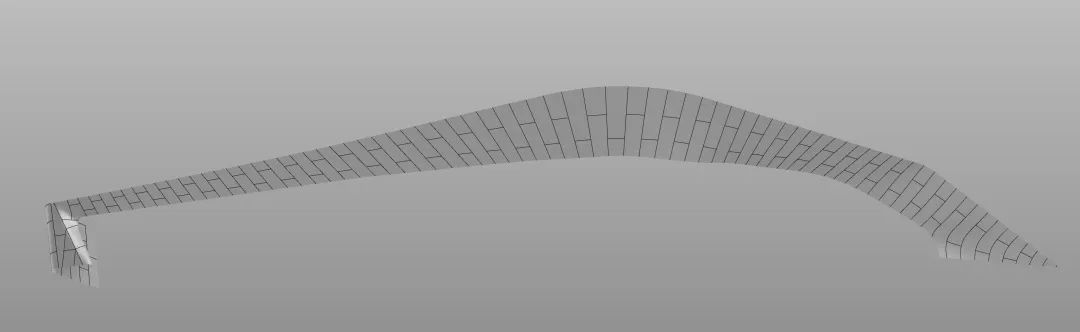

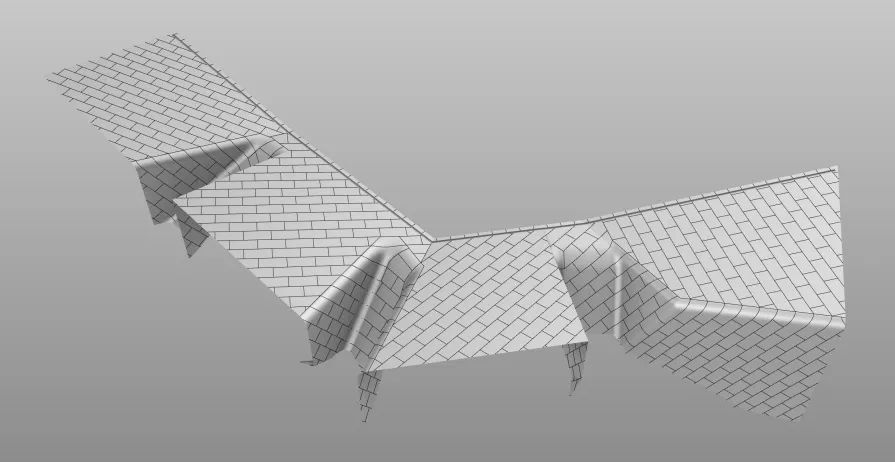

The Jinchang Yanbo Chenlu Demonstration Zone adopts hyperbolic aluminum plates, with a streamlined and smooth curvature, emitting a sense of modernity and artistry. However, for manufacturing and installation, this is a relatively difficult challenge.

▲Real time photography: Wu Qingshan

Firstly, 3D modeling is performed using software, followed by progressive decomposition using BIM software, including flattening, cutting, punching, chamfering, rolling, rolling, folding, and nailing After completing the production of individual pieces, welding and reinforcement assembly should be carried out without any errors in every detail.

5

Honeycomb aluminum plate

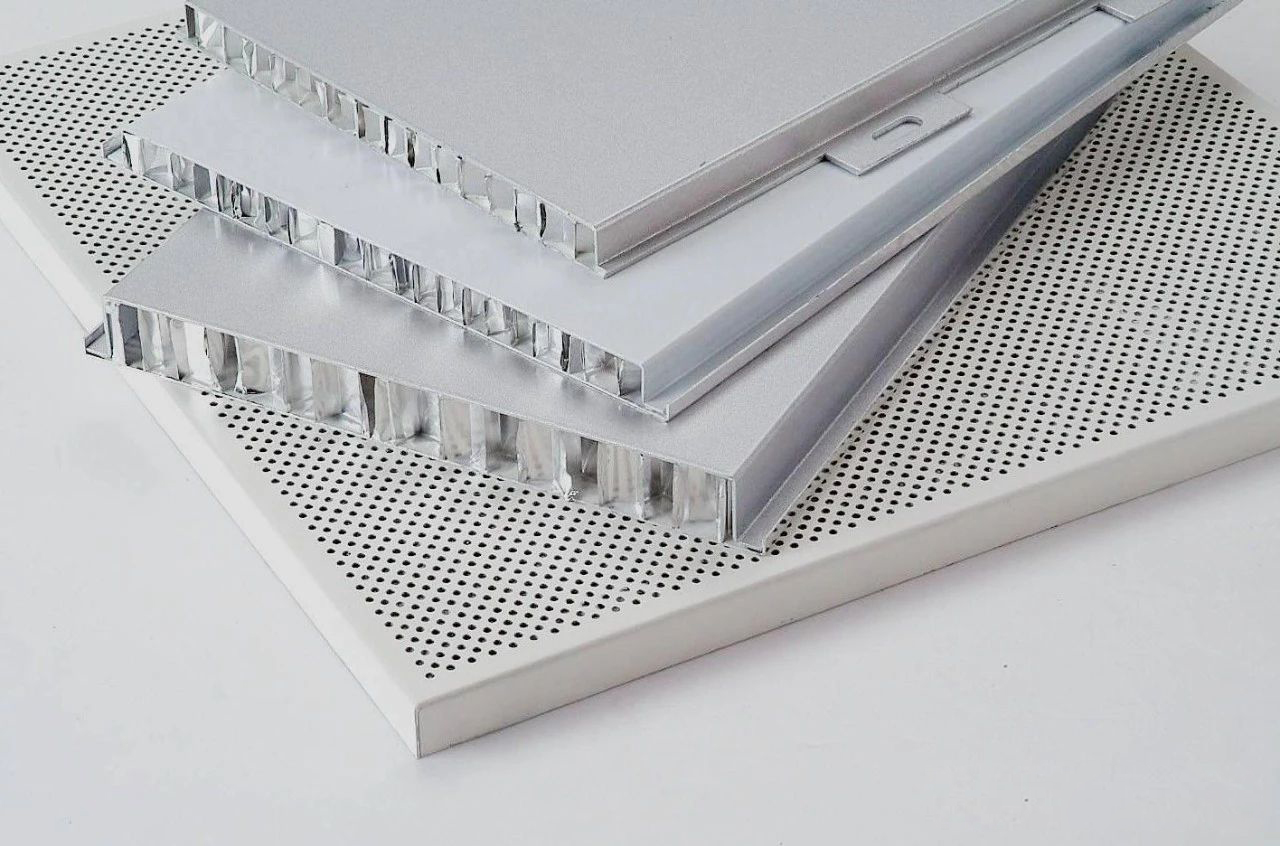

Honeycomb aluminum plate is a product series of gold composite plates developed by combining aviation industry composite honeycomb plate technology. This product adopts a "honeycomb sandwich" structure, which is a composite plate made of high-strength alloy aluminum plate coated with a decorative coating with excellent weather resistance on the surface, bottom plate, and aluminum honeycomb core through high-temperature and high-pressure composite manufacturing.

▲Honeycomb aluminum plate

This type of board will greatly enhance the overall structural integrity of the original aluminum plate, making it less prone to bending, allowing for larger scales and better flatness, but with a slight increase in cost.

Its characteristics include light weight, high strength, customizability, and easy installation (no welding, no visible nails). The common six types of aluminum honeycomb panel materials are: perforated honeycomb aluminum panel, carved honeycomb aluminum panel, wood grain honeycomb aluminum panel, stone honeycomb aluminum panel, curved/irregular honeycomb aluminum panel, and fluorocarbon honeycomb aluminum panel.

The fa ç ade of Nanjing CR Land · Guanyunrun Mansion also follows the principles of "precision" and "simplicity" in material selection, using luxury stones, ultra white glass, and honeycomb aluminum panels as the main materials, laying the overall gray tone, retaining the original texture of the stone, and inlaying golden thread feet at the same time to increase the detail durability.

The light and lively honeycomb aluminum panels extend outward from the roof, naturally connecting with the landscape corridor. The horizontal opening limits the boundary between the building and the sky, creating a soothing, harmonious, and tranquil inner atmosphere.

▲The spatial sense brought by horizontal eaves

In the vertical direction, local walls extend from the building volume, creating a sharp contrast between the thickness of luxury stones, the thinness of aluminum panels, and the lightness of glass, creating a subtle balance between "stability" and "refinement" in the entire building.

▲Wall columns under the corridor

The columns in the corridor are also presented in the form of partition walls, with horizontal open seams carved on top and horizontal shadows cast under the sky to carve details.

▲Material collage close-up

▲Structural details of multi material matching

The main entrance of China Resources Land Times City is the "Gate of the Times", with a 170 square meter large welcoming water feature layout on both sides. Above the door, a steel truss structure with a span of about 40 meters is used, achieving a span of about 20 meters without pillars. A total of about 2800 sky blue glazed ceramic panels, 2100 profiles, and thousands of light strips are used, and large honeycomb aluminum panels are selected at the bottom for modern luxury.

▲Real time City Scenery of China Resources Land

The grand ceremony of the door, reaching the realm of azure sky, presents the honor of returning home.

▲Real time city view of China Resources Land

Conclusion::

Overall, aluminum veneer has a broad market prospect as a new type of building material. With the rapid development of the construction industry and changes in consumer demand, the aluminum veneer market will continue to grow. Aluminum veneer manufacturers need to constantly innovate, improve product quality, and strive to develop more environmentally friendly materials to meet market demand and gain a competitive advantage.