01 Material Summary

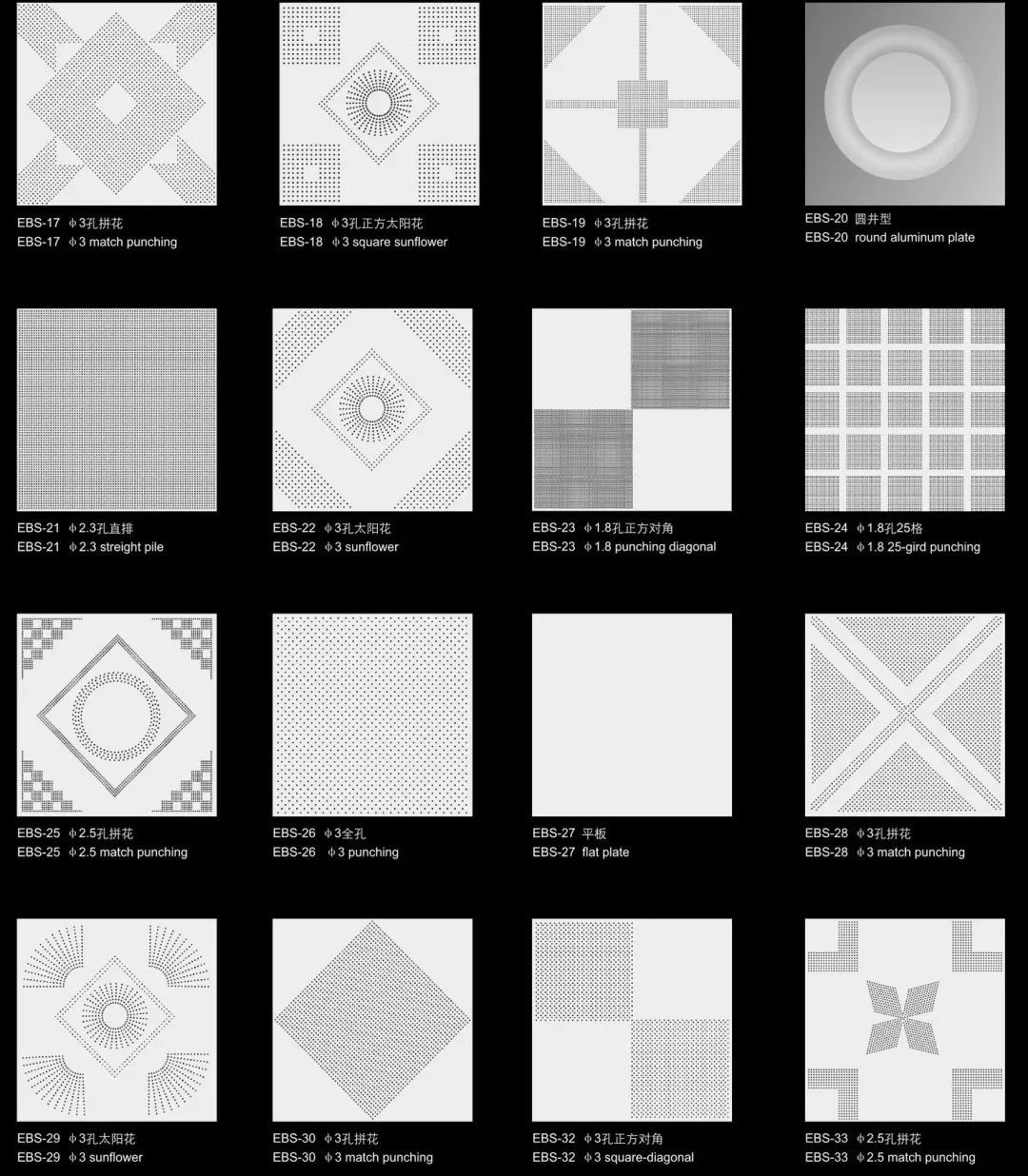

Ultra microporous sound-absorbing aluminum plate is a perforated aluminum plate with ultra-small pore size, which is made from metal aluminum plate as the substrate and processed through precision perforation technology. The ultra small aperture can reach 0.04x0.4mm, and the sound absorption effect is more than 30% higher than traditional perforated aluminum panels. The surface can be sprayed with polyester powder, or any color can be made through PVC film application.

02.Performance characteristics

a.Customizable

Punched aluminum plates can be customized according to customer needs in terms of size, shape, surface treatment, and color to meet their personalized needs.

b.Good material stability

The sound absorption and noise reduction effect is good, with moisture resistance, insect resistance, corrosion resistance, mold resistance, and no deformation.

c.Lightweight and high-strength

The board has high strength, lightweight per unit area, and a large width area with good flatness of the board shape.

d.Easy to clean and easy to install

Easy to install, easy to construct, each board can be disassembled and replaced separately.

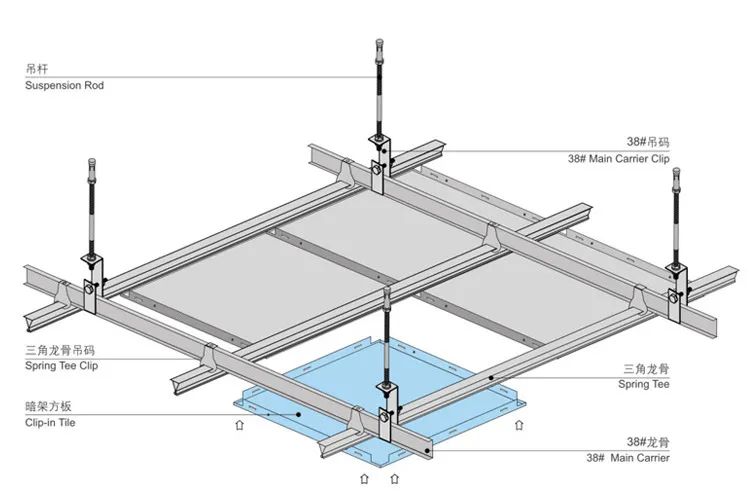

03.Construction technology

The construction sequence of the suspended ceiling is: snap the elevation control line and suspension rod point line → fix the suspension rod → install the supporting keel → install the aluminum plate.

a.Snap the elevation control line and suspension rod point line

Determine the elevation according to the requirements of the layout and the actual situation on site, and mark the elevation control line on the surrounding walls and columns. Determine the center point position of the suspension rod suspension point based on the aluminum plate ceiling, use a gray line to pop it out, with a spacing of less than 1200 and a distance of less than 300 from the edge. After the suspension point is popped out, it should be checked in a timely manner.

b.Suspension rod fixation

The selection and calibration of the supporting keel for the ceiling should meet the design requirements. Produce suspension rods according to the diagram and elevation requirements, and install fixed suspension rods according to the position of the suspension points.

c.Install supporting keel

Use fully threaded galvanized steel bars to lift the keel to its marked elevation position, install and fix it, and pay attention to arching the middle part of the keel according to the design requirements.

d.Installing aluminum plates

On the basis of installing and leveling the keel, lift the slats in place and clip them in from one direction in sequence for installation. First, press one side of the aluminum plate into the keel clamp, and then press the other side into the corresponding clamp.

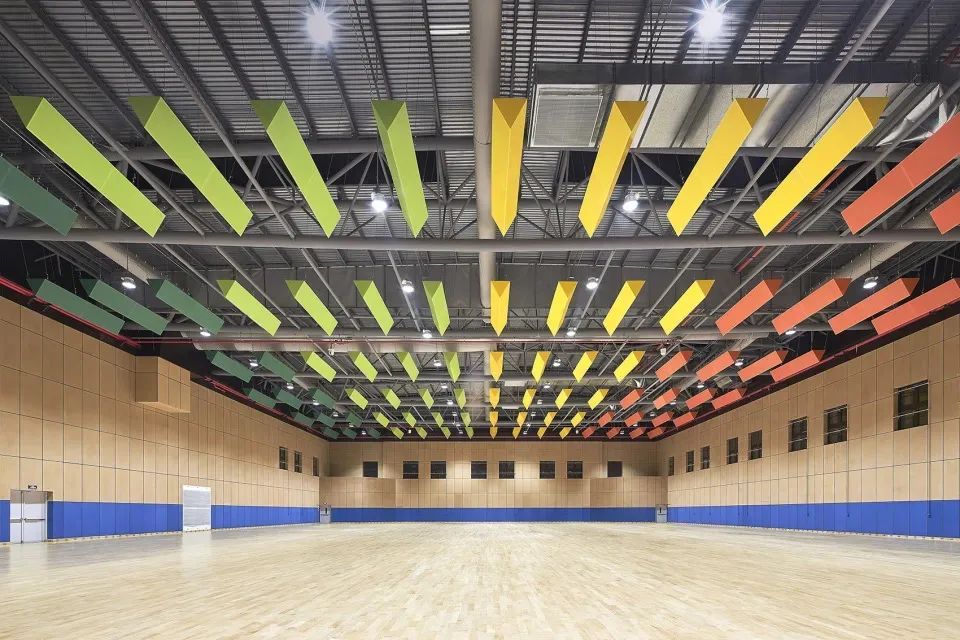

04.Application Cases

01.New Comprehensive Sports Center at Fudan Jiangwan Campus

02.The Chinese University of Hong Kong (Shenzhen) Self Library

03.Rongchuang Guangzhou Grand Theatre

04.Beijing Institute of Technology Cultural and Sports Center