01.

Material summary

Anodized aluminum plate is to place the aluminum plate in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode. Electrolysis is carried out under specific conditions and applied current.

A dense oxide film is formed on the surface of the aluminum plate, and the colorless and porous nature of the anodic oxide film is used to achieve the purpose of dyeing and protecting the aluminum matrix.

02.

Anodizing process

The anodic oxidation process mainly includes degreasing → etching → neutralization → anodic oxidation → coloring → hole sealing.

03.

Performance characteristics

A.Good processability

Anodized aluminum plate has strong decoration and moderate hardness. It can be easily bent and formed, continuous high-speed stamping, convenient and direct processing into products without complex surface treatment, which greatly shortens the product production cycle and reduces the product production cost.

B.Good weather resistance

Standard thickness oxide film (3μ m) The anodized aluminum plate is used indoors for a long time without discoloration, corrosion, oxidation and rust. Thickened oxide film (10 μ m) The anodized aluminum plate can be used outdoors and can be exposed to the sun for a long time without discoloration.

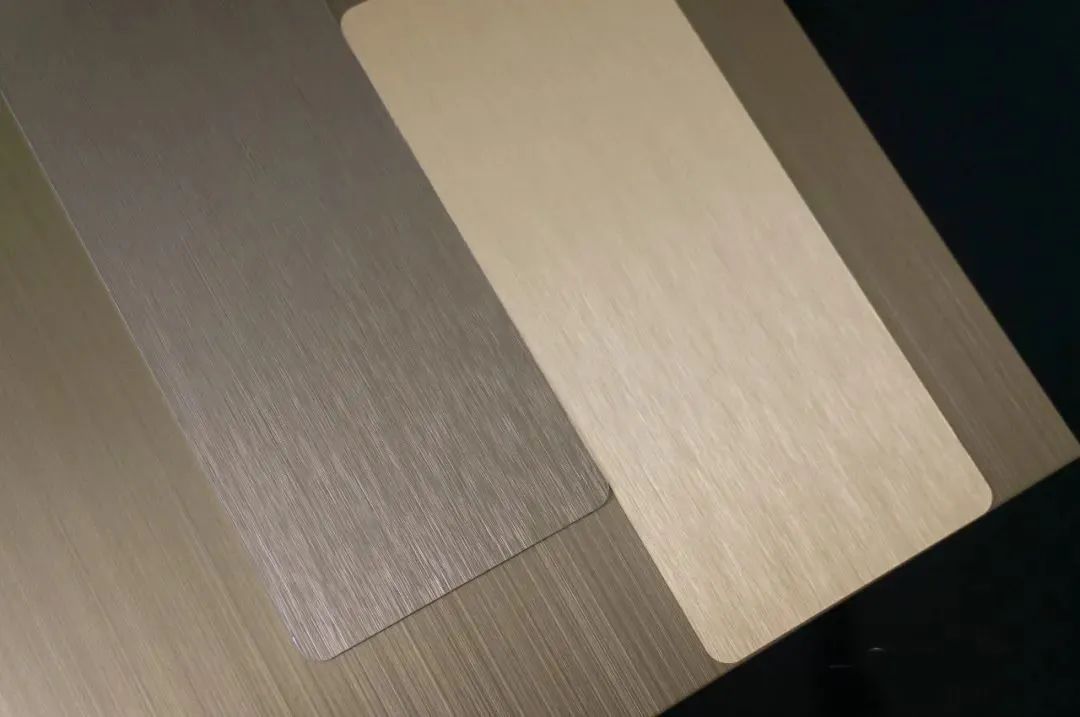

C.Strong metal sense

The anodized aluminum plate has high surface hardness, up to gem level, good scratch resistance, no paint coverage on the surface, retains the metal color of the aluminum plate, highlights the modern metal feeling, and improves the product grade and added value.

D.High fire resistance

Pure metal products, without paint and any chemical substances on the surface, do not burn at 600 ℃ and do not produce toxic gases, which meet the requirements of fire protection and environmental protection.

E.Strong stain resistance

No fingerprints, stains, easy to clean, no corrosion spots.

F.Strong applicability

It is widely used for metal aluminum ceiling, curtain wall aluminum plate, aluminum plastic plate, fireproof plate, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc.

04.

Application area

Anodized aluminum plate has a wide range of applications, such as architectural decoration, furniture and household appliances.

A. Building decoration industry, such as building facade, curtain wall, indoor wall top surface, etc.

▲Building exterior wall

▲Top surface of indoor wall

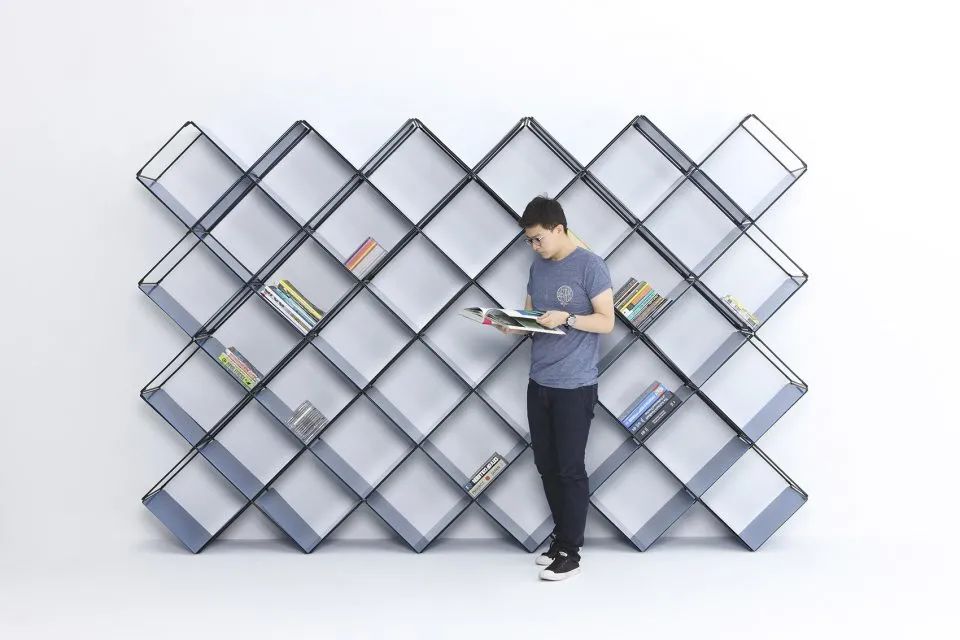

B. In the field of furniture and household appliances, anodized aluminum plate is a favorite decorative panel by manufacturers.

▲Bookshelf

▲Refrigerator air duct

▲Air heater

05.

Application case

01.Zhigu AI technology center

02. Reconstruction and decoration of karma office building

03.Concepts retail store

04.Yinchuan Construction Development Group grand reading City office building headquarters

Transferred from: design materials