Aluminum is widely present in nature. Aluminum ranks third in content in the Earth's crust, only behind oxygen and silicon. It accounts for about 75.1% of metals and is the most abundant metallic element in the Earth's crust, making it a relatively easy to obtain metal.

Aluminum alloy used in new energy vehicles can improve efficiency, reduce fuel consumption, and save energy and emissions. All aluminum body is one of the development directions for lightweight new energy vehicles. The rise of new energy vehicles has also opened up a blue ocean for the application of aluminum alloys in vehicles. Due to energy limitations, lighter aluminum alloy bodies can reduce energy consumption and become one of the main breakthrough directions for extending mileage.

The aluminum industry has vibrant vitality and is an important component of the materials industry. In the past decade, with the accelerated development of the domestic aluminum industry, it has approached the world's advanced level in terms of industrial scale and production technology. It has successfully cultivated multiple modern aluminum industry groups that are renowned worldwide and developed a series of high-performance new aluminum alloys.

China is a major producer of aluminum alloys. The demand for aluminum alloys in the entire market is still increasing every year, and those large and medium-sized aluminum alloy production enterprises are the biggest beneficiaries of this market.

One major advantage of aluminum is its ability to be reused, while saving 95% of the energy required in the original aluminum production process. Compared with other materials, it is more environmentally friendly, and the recycled aluminum can be used in almost any field. At present, aluminum plays an important role in the field of waste car disposal due to its high waste value in metal recycling.

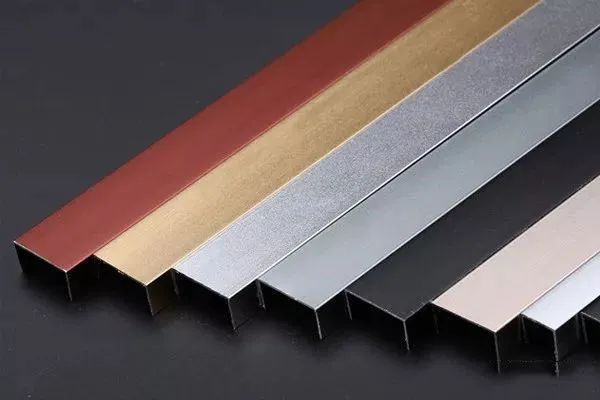

For expanding the application field of aluminum, the cooperation mechanism between upstream and downstream will be used as a starting point. On the basis of assisting the Ministry of Industry and Information Technology in establishing a cooperation mechanism for upstream and downstream of civil aircraft aluminum materials, and with the guidance and support of the National Development and Reform Commission, the Ministry of Industry and Information Technology, the Ministry of Housing and Urban Rural Development, the Ministry of Transport, and the General Administration of Quality Supervision, Inspection and Quarantine, backbone enterprises in the aluminum processing industry will be established, as well as industry organizations such as the China Association of Automobile Manufacturers, the China Construction Industry Association, and the China Shipbuilding Industry Association, as well as backbone enterprises The consultation and exchange mechanism of research institutes and other units jointly formulates the process technology, product quality, and engineering construction standards for product application. Continue to consolidate and expand the application of aluminum materials in trailers, coal trucks, construction templates, and building aluminum enclosure panels, and strive to promote the application of aluminum materials for civil aircraft, automotive body thin plates, urban new energy bus bodies, ship aluminum alloy plates and aluminum alloy flood walls, urban aluminum structure pedestrian bridges, and bridge inspection platforms.

From the perspective of applications in developed countries and regions, aluminum products are becoming a "new favorite" in transportation fields such as automobiles, aviation, ships, and railways. Among them, the demand for aluminum in the transportation sector in Europe has tripled, and this data will continue to grow exponentially in the future. In the transportation sector such as fully aluminized passenger car trailers, aluminum oil tank trucks, C80 coal transport trucks, high-speed rail, urban rail, subway, etc., an additional 10 million tons of market aluminum capacity can be added in the future. The promotion of "large aircraft" and ship yacht projects also brings development opportunities to the aluminum industry.

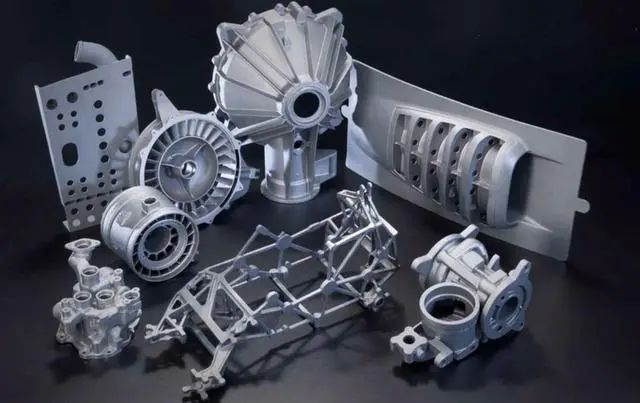

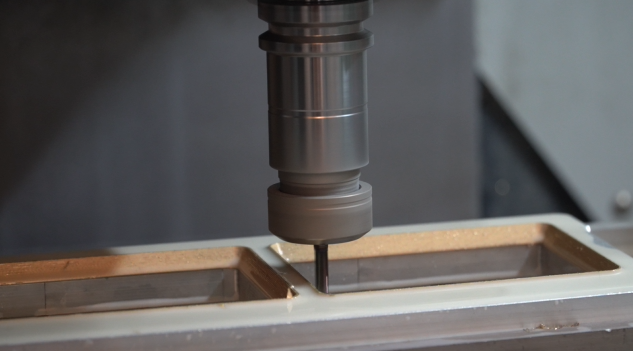

At present, the application of aluminum alloy profiles, plates and strips, castings, and forgings in automobiles is becoming increasingly widespread. In the next five years, the annual compound growth rate of aluminum alloy sheets for passenger car bodies may exceed 25%.

It is worth noting that in recent years, the trend of lightweighting in the four major transportation sectors of automobiles, rail transit, aviation, and ships has become increasingly clear. Aluminum alloy, as an important profile material for achieving lightweight transportation, has a promising future for development.

The use of aluminum materials in transportation equipment is more than 30% lighter in weight than the use of steel materials, and the safety factor is also reliably guaranteed. Reducing the weight of transportation vehicles can reduce fuel consumption and improve transportation efficiency, which is of great significance for reducing environmental pollution. Therefore, the use of aluminum alloy for lightweight in the transportation equipment manufacturing industry is a major trend. With its lightweight and excellent oxidation and corrosion resistance, the application of aluminum alloy in transportation will become increasingly widespread in the future. It is estimated that globally, the growth rate of terminal aluminum consumption is over 6%, and the growth rate of aluminum demand for transportation will exceed 8%.

In the aviation industry, aluminum alloy materials have been widely used for nearly a century. Under the competition between titanium alloys and composite materials, the proportion of aluminum alloys used in the aviation industry, especially in military aviation, has decreased, but the performance requirements for aluminum materials are increasing. The development of ultra-high strength aluminum alloys, high damage tolerance alloys, and high-strength, high toughness, and high hardenability alloys for large integral structures have become the main trends.