Preface::

The most commonly used material in sloping roof structures is tiles, such as mud tiles, glazed tiles, ceramic tiles, and so on. However, the above tiles all have issues with usage time limits and waterproofing of joints. Therefore, in order to address these issues and better match the aesthetic of modern architectural design, metal tiles have emerged.

01.What is a metal tile

"Metal tile" refers to a type of material made from metal as the basic material. According to the production process, it can be divided into stone faced metal tile, painted metal tile, and metal natural color tile. It can replace traditional glass tile, clay tile, cement tile, resin tile, and asphalt tile, and is a new type of external decorative material for buildings.

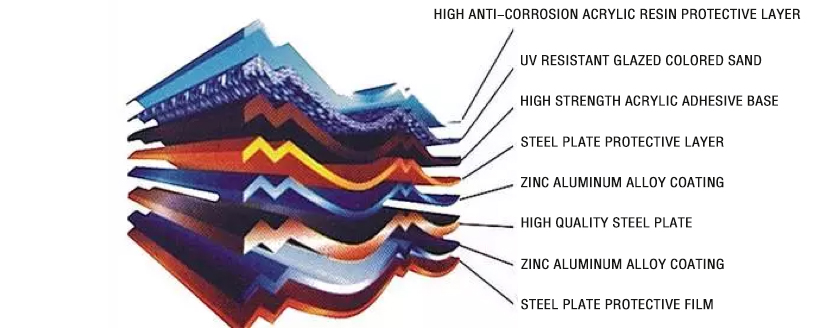

▲The composition of metal tiles is illustrated by colored stone metal tiles

Metal tiles, as roof materials, combine the structural layer and waterproof layer into one. There are many types of tile materials, including zinc plate, aluminum zinc plate, aluminum alloy plate, aluminum magnesium alloy plate, alloy plate, copper plate, stainless steel plate, and so on.

02.Material properties

Lightweight: Metal tiles have a strong weight and can effectively reduce the weight load borne by buildings, ensuring their safety and stability.

Fire proof and positive combustion: Metal tiles have strong fire resistance performance, with a fire resistance rating of A level, will not burn, and also have a certain flame retardant ability.

High stability: the metal tile is very solid, which can withstand rainstorm, earthquake, ice and other impacts, and the wind resistance can be up to 120mp (miles/hour). Accurate matching and design can make the roof more sturdy, greatly reducing the possibility of roof collapse.

Multiple options: Due to the current production of metal tiles on the market, they come in a wide variety of colors and shapes. Therefore, consumers have more options when making purchases.

Easy construction: Metal tile materials do not have high structural requirements for buildings, and the design and construction are relatively convenient and simple, making them suitable for various roof shapes. Moreover, the material itself is lightweight and the accessories used are simple, making the overall installation process relatively easy, greatly reducing the intensity of construction and shortening the construction period.

Recycling and reuse: Metal tiles have another characteristic, which is their recyclability. After recycling, they can be reused 100% without causing pollution or harm to the environment.

03.Material classification

1、From the perspective of surface texture:

Stone surface metal tile: a stone surface metal tile made by molding aluminum zinc coated steel plates into various tile shapes, and then using water-based acrylic resin as the adhesive to bond natural basalt particles as the surface; Also known as colored stone metal tiles.

Painted metal tiles: The surface of metal substrates such as aluminum zinc coated steel plate, galvanized steel plate, aluminum magnesium alloy, etc. is painted and sprayed to form a tile shape for use on the roof.

Metal Natural Color Tile: Metal Plate "Natural Color" Production: Pure copper plate, zinc plate, and other surfaces are directly processed for roofing without coating treatment, mostly used for high-end roofs.

2、Metal materials are divided into:

01、Aluminum zinc coated steel tiles:

a、Super strong corrosion resistance;

b、Anti high-temperature oxidation, no discoloration or deformation occurs in a high-temperature environment of 315 degrees Celsius;

c、The thermal reflectivity of this product is higher than 75%, which is twice that of galvanized sheet.

02、Stainless steel tiles:

a、Beautiful surface and diverse usage possibilities;

b、Good corrosion resistance and longer durability than ordinary steel;

c、High strength, therefore the possibility of using thin plates is high;

d、High temperature oxidation resistance and high strength, therefore able to resist fire;

e、Room temperature processing, which is easy to plastic process;

f、Cleanliness, high smoothness, and good welding performance.

03、Aluminum magnesium manganese tiles:

a、Lightweight; The density of aluminum is 2.73g/cm3, which is only one-third of that of steel;

b、High strength; High strength can be achieved through ingredient configuration, processing, and heat treatment methods;

c、Corrosion resistance: With self rust prevention ability, the formed oxide layer can prevent metal oxidation and corrosion, and has good acid and alkali resistance;

d、Good plasticity and easy processing;

e、Good conductivity; Non magnetic and low spark sensitivity can prevent electromagnetic interference and reduce flammability in special environments;

f、Easy installation; Aluminum metal can be connected through various methods such as riveting, welding, and adhesive bonding. It is environmentally friendly and 100% recyclable.

▲Aluminum zinc steel tile | stainless steel tile | aluminum magnesium tile

4、Bowl Zinc Tile:

a、Long service life, with a lifespan of 80-100 years for the metal surface layer;

b、By relying on the zinc carbonate protective layer formed by itself, it can prevent further corrosion of the surface layer, without the need for paint protection, with a true metallic texture, and has the characteristics of automatic healing without leaving scratches and maintenance free after scratching;

c、The board has good elongation and tensile strength;

d、Good plasticity;

e、Can be used for 3D curved profiles on site.

5、Bowls of zinc bonded tiles:

a、Long service life. The surface of the bowl zinc alloy panel can naturally form a dense oxide layer (zinc carbonate salt) to prevent further corrosion, and can be used in environments with poor atmospheric conditions;

b、The panel does not require painting or other anti-corrosion treatment and has a metallic texture;

c、The panel has a self-healing function, which automatically heals without leaving any marks after scratches;

d、Strong rigidity, not easily bent or deformed.

6、Copper tiles:

a、Good corrosion performance, durable, and recyclable;

b、It has good processability and can be easily made into complex shapes;

c、And it also has beautiful colors

▲Bowl Zinc Tile | Iron Zinc Adhesive Tile | Copper Tile

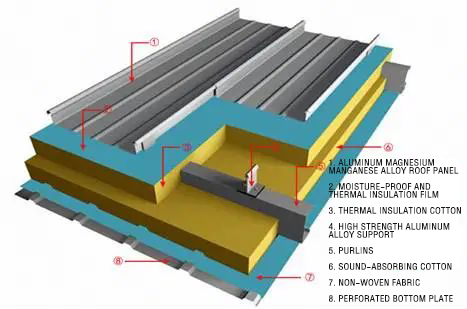

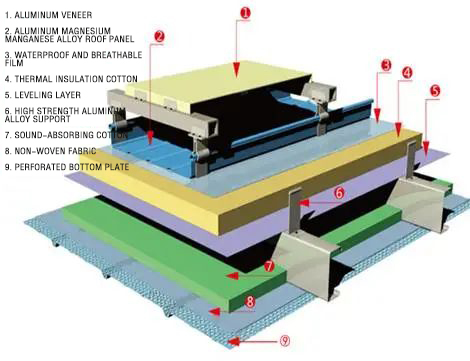

04. Construction process of roof system

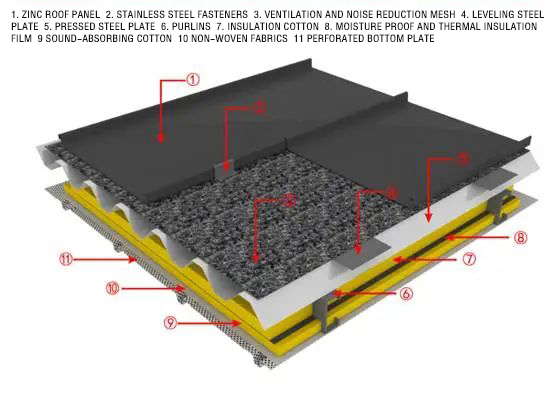

1、25/32 typical system:

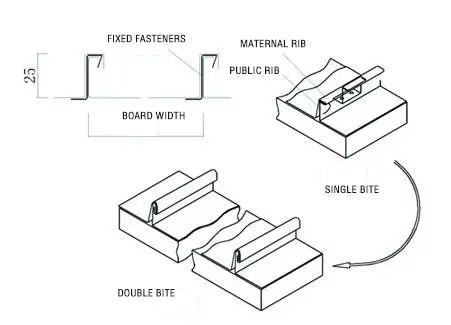

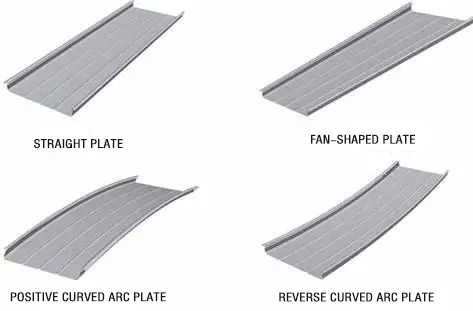

Commonly used for 23 ° sloping roofs, curved roofs, and roofs with a tilt of less than 25 degrees, the 25/32 meter high interface edge has become an international standard through prefabricated bottom plate technology.

The bending and sealing of the standing edge can be done manually or by machine, and special designs such as convex curves, concave curves, or cone combinations can be easily achieved, adding modern design style to traditional architecture. The overall structure is waterproof, safe, and can resist high negative wind pressure, especially in typhoon and rainstorm areas.

▲25/32 typical system

▲25/32 typical system

▲25/32 typical system

▲25/32 typical system

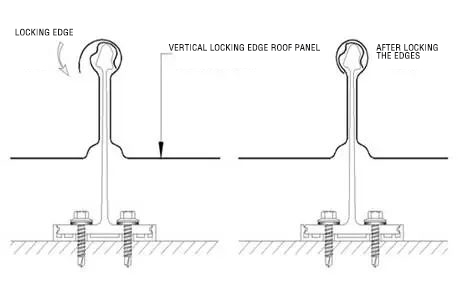

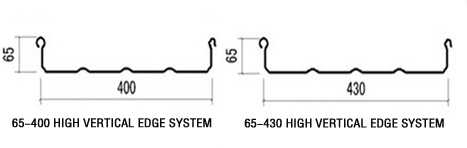

2、65 Typical Systems: (This system is suitable for roofs or walls with a slope of 21.5 °)

a、Structural self waterproof design, with upright locking edges between panels, ensuring reliable waterproofing;

b、The exhaust outlet, skylight, and pipeline outlet can be directly threaded out, and the accessories are welded to ensure water tightness;

c、The large-span (s200m) single board can be fully extended without connecting ports or nail holes, with simple construction and firm locking;

d、The connection between the bite edge and the concealed support can solve the destructive force caused by thermal expansion and contraction;

e、The insulation pad of the support solves the heat conduction problem of the metal roof system.

▲Typical system after 65

▲Typical system after 65

▲Typical system after 65

▲Typical system after 65

▲Typical system after 65

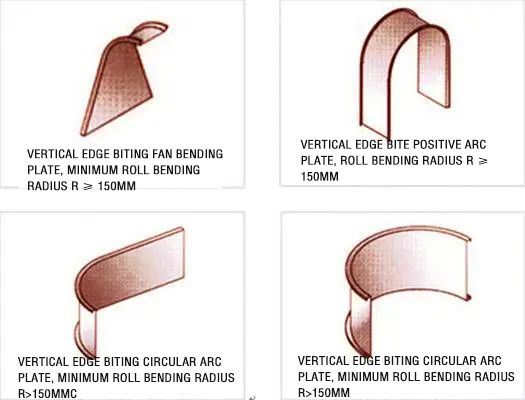

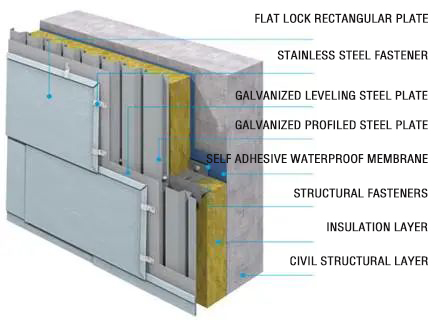

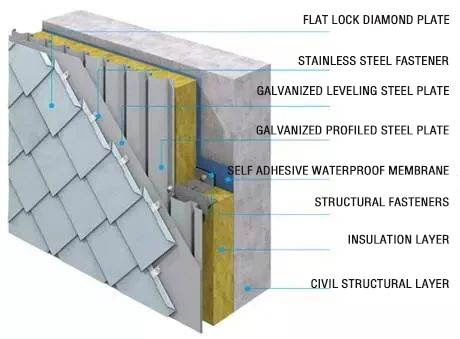

3、Flat lock buckle system: (This system is suitable for sloping roofs and curtain wall systems above 230)

The overall structural waterproofing and drainage system has a strong sense of hierarchy and outstanding visual effects. In classical architectural style, the tile flat locking system can be installed on the surface of almost any shape of building, achieving geometric diversity in architectural design; Easy to install, fixed on the lower support structure with fasteners, without the need for complicated mechanical installation.

▲Flat lock buckle system

▲Flat lock buckle system

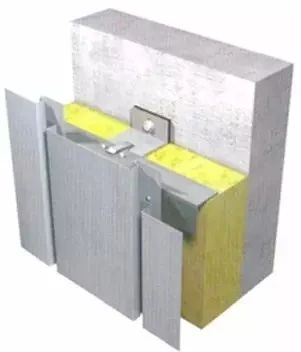

4、Embedded panel wall system: (suitable for flat or curved walls)

It can be laid horizontally or vertically. You can choose different sizes of board types, with excellent surface smoothness and elegant appearance of board seams, making installation very convenient. Common materials: zinc plate, antique plate, aluminum magnesium alloy plate, stainless steel plate.

▲Embedded panel wall system

5、Construction process

Measurement and laying out, leveling layer construction, JS waterproof construction, laying out, L-shaped corner code installation, water bar installation (square steel), laying out, hanging tile installation (square steel), metal tile installation, board joint treatment, and surface cleaning.

6、 Metal tile installation:

a、 Fix the metal tiles on the hanging tile strip using horizontal nails with metal dovetail nails (see attached figure). It is required that each tile should be fixed firmly with no less than 5 pieces, and extend into the hanging tile strip by no less than 20mm;

b、The installation sequence is from bottom to top, from left to right, or from right to left;

c、When the tiles need to be cut, make a reserved amount for bending and draw the cutting line. Use a dedicated cutting knife to cut the edges, and use a dedicated folding machine to handle the folded edges;

d、Node processing.

Board joint treatment: neutral silicone adhesive sealing treatment is used. Firstly, remove the protective layer from the board surface and clean the dust and oil stains at the board joints. After drying, apply a layer of sealant. When the adhesive surface is initially dry, use a putty knife to scrape the surface into the desired shape and make it flat and smooth.

Surface cleaning: After the construction is completed, clean the roof, clean the items on the roof, and keep the roof clean.

05.Classic Cases

1、Xinya Primary School in Xiasi Village, Jiange County, Sichuan Province

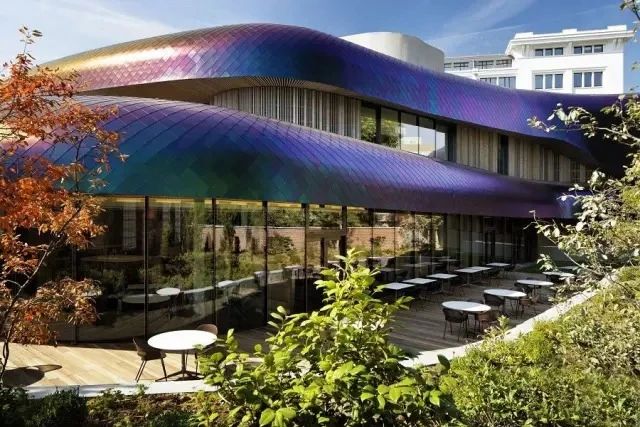

2、Renovation and expansion of French corporate headquarters

3、Taitung Taimali Jieda Relay House

4、Japanese "Light and Shadow Curved Wall"

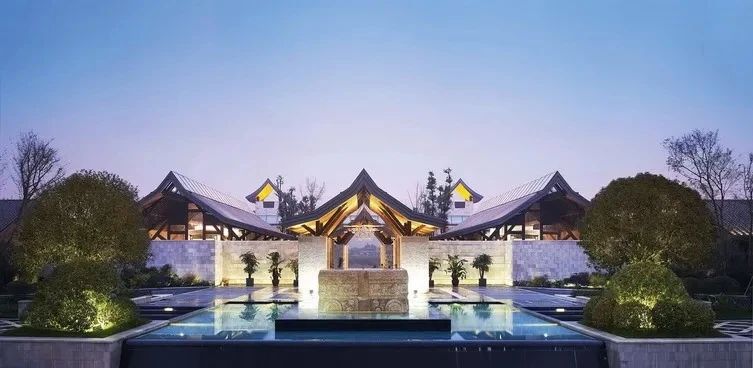

5、Chengdu China Pavilion

The article is from Weixin Design