01.What is honeycomb board

Honeycomb board is a high-strength new environmentally friendly building composite material developed based on the principles of honeycomb structure bionics. It is called honeycomb board because it uses honeycomb core as the base layer.

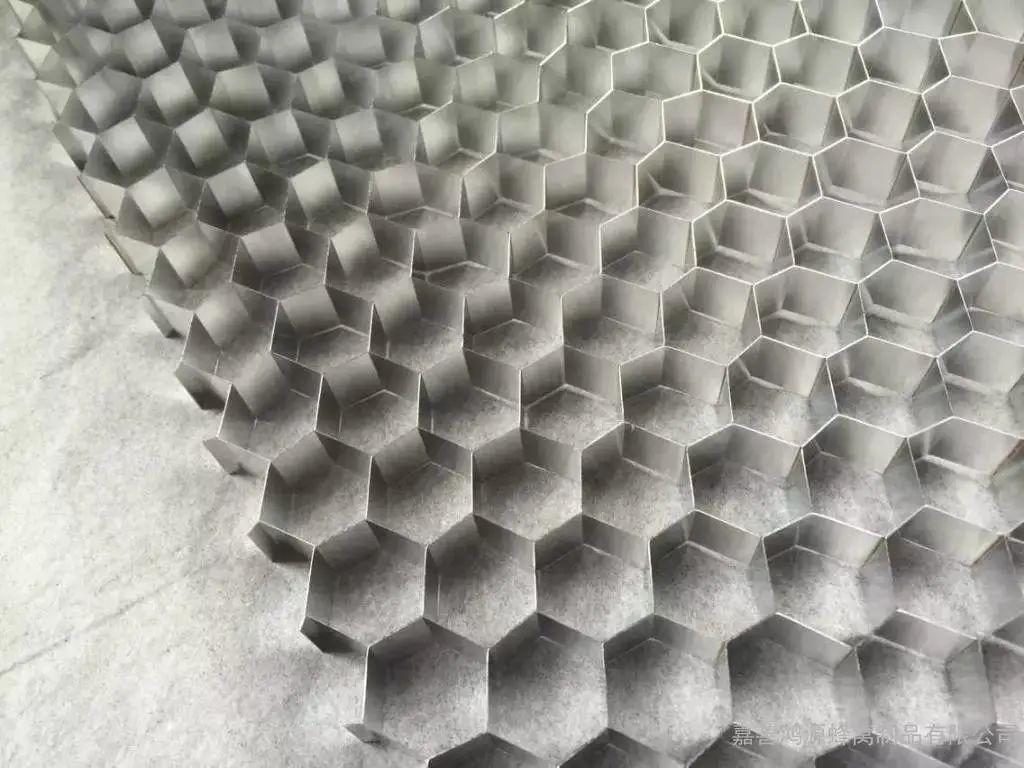

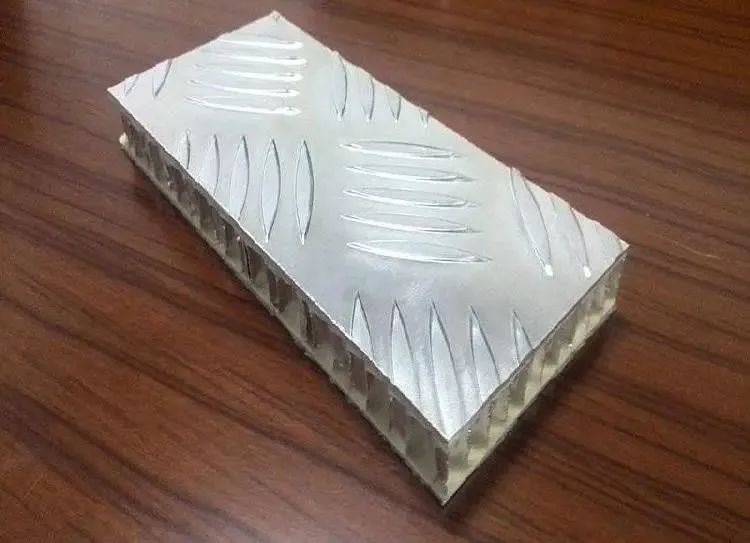

▲Aluminum honeycomb core layer

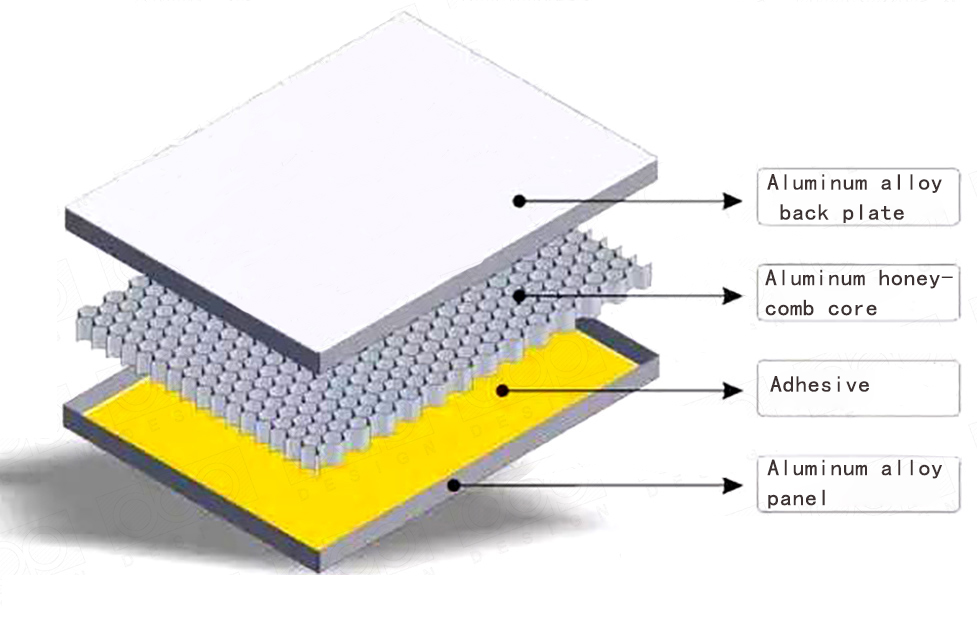

And honeycomb aluminum plate is a series of metal composite plate products developed by combining aviation industry composite honeycomb plate technology. Adopting a "honeycomb sandwich" structure, which is a composite plate made by high-temperature and high-pressure composite manufacturing of high-strength alloy aluminum plate coated with a decorative coating with excellent weather resistance on the surface, bottom plate, and aluminum honeycomb core.

▲ Schematic diagram

This type of plate will greatly enhance the structural integrity of the original aluminum plate, making it less prone to bending, allowing for larger dimensions and better flatness.

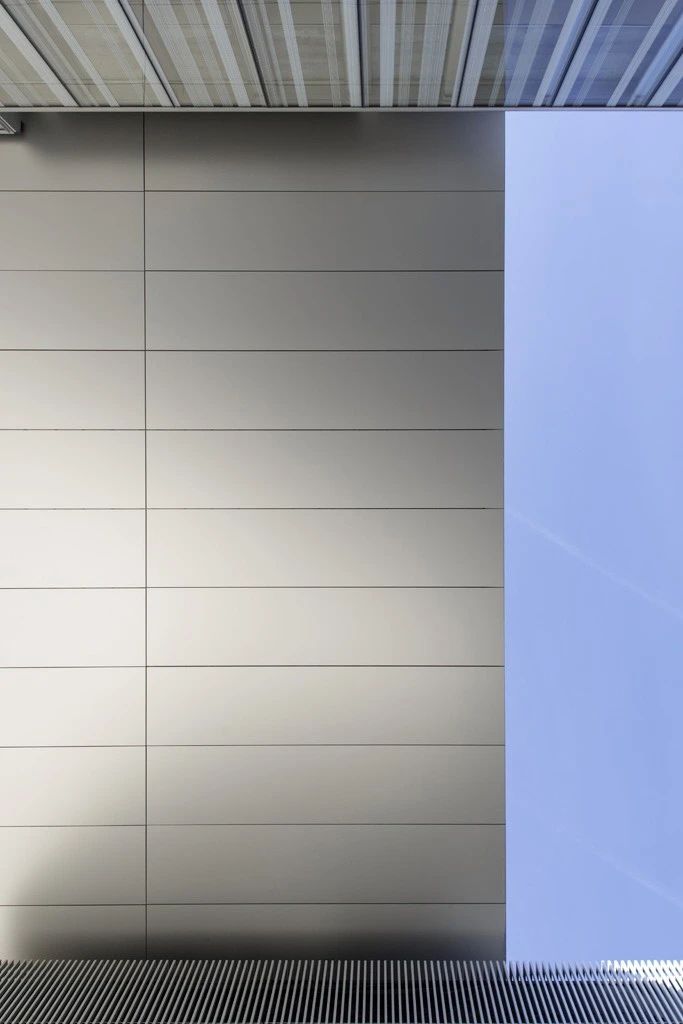

▲Application of suspended ceilings in Jacobin Cultural Plaza

[Performance characteristics]

① Large panel surface and high flatness: Without any reinforcement measures, the honeycomb aluminum panel surface size can reach 1500 * 5000mm and can maintain excellent flatness.

② Lightweight: The honeycomb aluminum panel weighs only 5-5.5kg/square meter, greatly reducing the load-bearing capacity of the building.

③ High strength: can withstand high strength pressure and shear, not easily deformed, and can meet the wind pressure resistance requirements of super high-rise buildings.

④ Product customization: Honeycomb aluminum panels can be customized according to customer needs in terms of size, shape, paint finish, and color.

⑤ Easy installation: It can be installed in any order, and each wall panel can be disassembled and replaced separately, improving the flexibility of installation and maintenance, and reducing costs.

⑥ Box structure: The honeycomb aluminum plate is a box structure with surrounding edges, which has good sealing performance and improves the safety and service life of the honeycomb aluminum plate.

⑦No welding and no exposed nails: When installing the base and surface layers of honeycomb aluminum panels, corner codes and screws are used to connect them, eliminating the need for skeleton welding. Moreover, after the surface layer is installed, there are no exposed nails on site, making it clean and tidy.

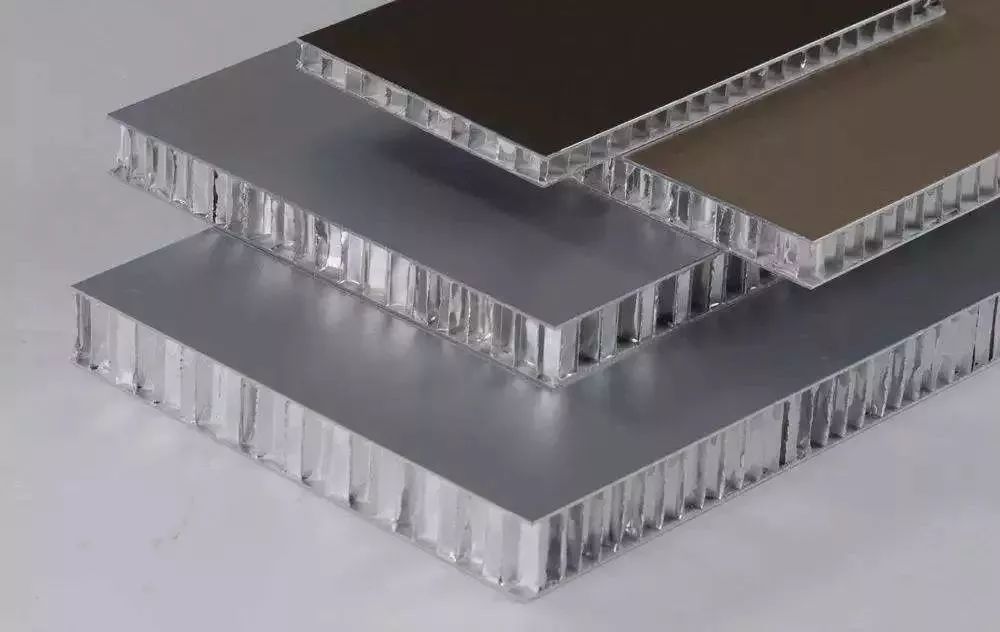

▲Realistic image

[Common 6 types of aluminum honeycomb panel materials]

① Punched honeycomb aluminum plate

Punched honeycomb aluminum plate is a metal decorative plate that uses CNC punching equipment to create various shapes of holes on the surface of the honeycomb aluminum plate. Various fillers can be added according to various special needs.

② Carved honeycomb aluminum plate

Carved aluminum panels are various artistic design patterns carved on the surface of honeycomb aluminum panels using a carving machine. By combining different patterns with different environments, traditional design concepts are broken through, making the aluminum carved lines more lively and elegant.

③ Imitation wood grain honeycomb aluminum plate

Imitation wood grain honeycomb aluminum plate is a natural wood grain effect made by powder treatment process on the surface of the aluminum plate, with true color and texture, and firm and wear-resistant pattern.

④ Imitation stone honeycomb aluminum plate

Imitation stone honeycomb aluminum plate is a new decorative material that is based on aluminum plate and processed through a special spraying process to give honeycomb aluminum plate a strong three-dimensional sense of stone.

⑤ Curved and irregular honeycomb aluminum plate

Arc-shaped and irregular honeycomb aluminum panels are made into shapes such as circular honeycomb aluminum panels, conical honeycomb aluminum panels, and curved honeycomb aluminum panels according to customized requirements. The shaped honeycomb aluminum panel is a metal decorative material with strong decorative and aesthetic properties.

⑥ Fluorocarbon honeycomb aluminum plate

The surface coating of fluorocarbon honeycomb aluminum plate can be customized according to needs, and the process can be divided into fluorocarbon spraying, powder spraying, and fluorocarbon pre roller coating. The fluorocarbon spraying surface coating can be divided into two coatings and three coatings according to the processing technology. The powder spraying surface coating is one coating and one baking, and the color of the fluorocarbon coating can be freely selected.

[Honeycomb aluminum plate processing technology]

Cold pressing:Single processing takes a long time, and those with the same size specifications can be cold pressed together. It is suitable for batch processing of a single specification, with a flat surface and stable quality.

Hot pressing:Short single processing time, suitable for projects in various specifications. Due to the significant temperature difference immediately after moving out of the plate, the large plate may experience slight deformation and require cold pressing and leveling treatment.

Vacuum pumping:suitable for processing irregular and hyperbolic plates. If the plate is too large or the stress is slightly high, there may be residual bubbles during vacuum pumping, resulting in uneven surface.

Continuous production:High production efficiency, stable product, requiring secondary edge sealing, suitable for mass production of flat panels.

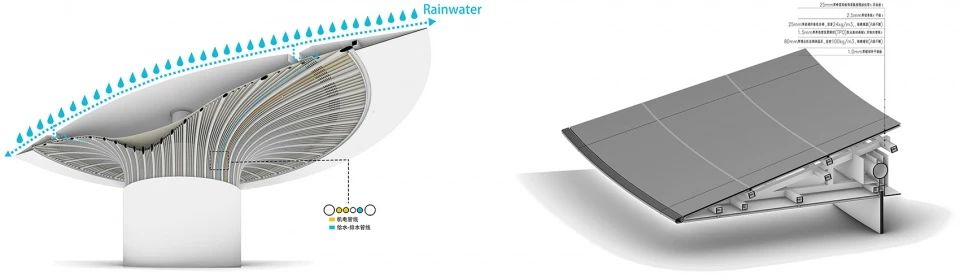

▲Installation sample of the renovation project for the sail curtain wall of the China Maritime Museum

[Construction process]

① Wall honeycomb panel construction

Measurement and setting out - Base layer cleaning - Snap keel installation line - (Base layer and keel) Drilling (drilling) holes - Installation of expansion bolts - Fixation of base layer keel - Drilling of screw holes - Installation of anti slip buckles - Installation of peak plate - Gluing - Sealing strip - Acceptance

② Ceiling honeycomb panel installation, measurement, pulling wire installation, suspension rod installation, L30 * 2 galvanized base angle steel keel installation, honeycomb panel special connection accessories installation, honeycomb panel installation, surface cleaning, sub item inspection and acceptance

02.Application of honeycomb panels

Honeycomb aluminum panels are widely used in aviation manufacturing, building curtain walls, exterior wall cladding, indoor ceiling decoration, commercial transport and container vehicle bodies, buses, trains, subways, and rail transit vehicles, etc. In addition, the selection of honeycomb aluminum panels is diverse, such as solid wood, aluminum panels, natural stone, stainless steel panels, etc. can be made into honeycomb panels, making material selection convenient.

A. Application of building curtain walls

Honeycomb aluminum panels, due to their excellent performance, can be designed to create large and straight exquisite walls, with strong flexibility in size and shape.

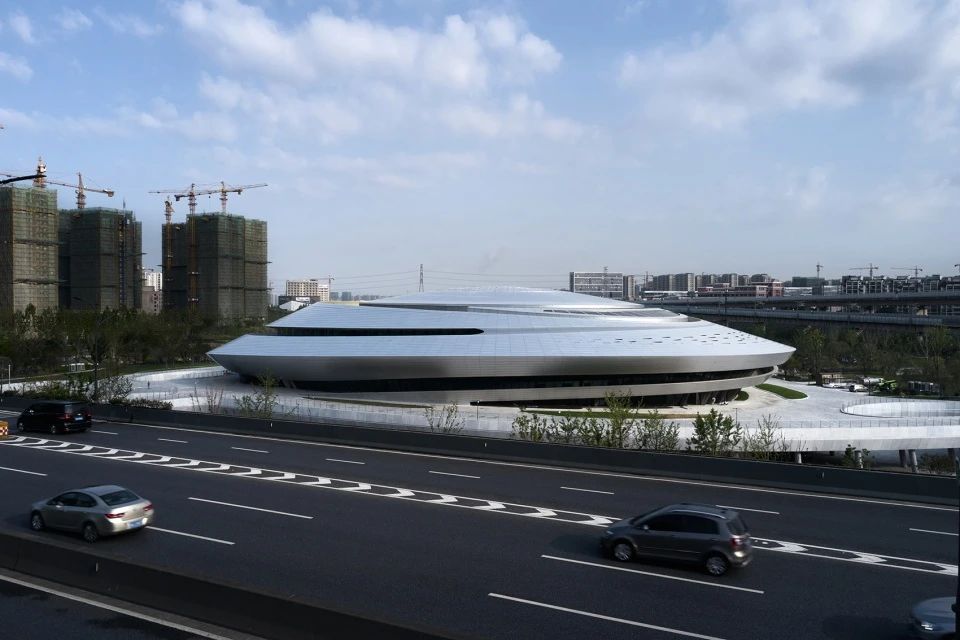

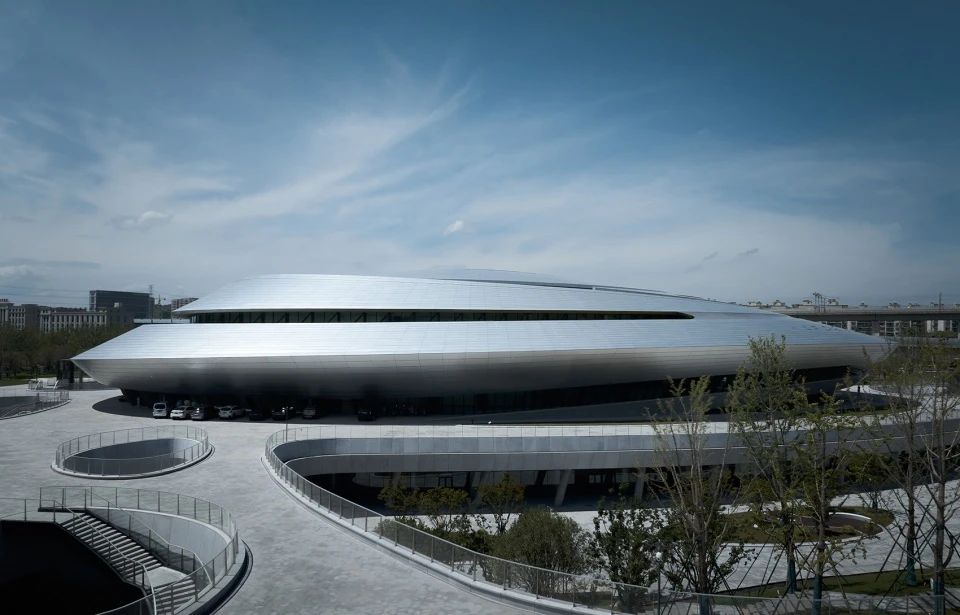

Hangzhou Esports Center, China

Design: Zhongnan Architectural Design Institute Co., Ltd

The building surface is covered with hyperbolic anodized honeycomb aluminum panels, and against the backdrop of the sky, the facade presents a slight reflection of the surrounding environment. With the conversion of different angles on the surface and the movement of crowd viewpoints, the sense of "weight" of the building is gradually reduced.

Chinese Maritime Museum Sail Body Moulding Wall

Design unit: Shanghai Architectural Design and Research Institute Co., Ltd

Collaborative Design: German GMP Architects

The central sail roof of the main museum adopts a hyperbolic honeycomb aluminum panel curtain wall, with an overall height of about 58m and a metal wall area of about 15000 square meters.

Zhiya Library in the Eastern New Area of Chengdu

Design: China Southwest Architectural Design and Research Institute Co., Ltd

The roof and eaves of the building are made of silver gray honeycomb aluminum panels to ensure the finished flatness. The detail completion of the eaves greatly affects the overall effect. After multiple rounds of dispersion research, a customized curved profile with a radius of 25mm was ultimately selected, utilizing the unique shape of the curved surface to reduce the visual thickness of the eaves.

Hangzhou Green City Jianfa Qinyuan Residential Project

Architectural Design: GLA Architectural Design

The exterior facade of the building adopts bee shaped aluminum panels and dark European gray glass, using the delicacy of aluminum profiles to outline the transparent geometric shape of honeycomb aluminum panels and large 10Ww-e glass.

B.Ceiling application

The Fengwo aluminum panel ceiling system provides designers with a wide range of choices from panel materials, shapes, installation systems, colors, and surface treatments, showcasing a variety of ceiling performance effects and providing excellent design freedom.

Beijing Daxing International Airport

Design: Zaha Hadid

The indoor color of the airport is mainly white, and the suspended ceiling of the terminal building is decorated with aluminum honeycomb panels.

JiaXing Railway Station

Design: MAD

The overall interior design of the train station is in a white minimalist style. The waiting hall, suspended ceiling, and tunnel walls are all made of anodized aluminum honeycomb panels, effectively absorbing sound and reducing noise.

ENSHADOWER Hangzhou Gate Store

Design: say architects

The ENSHADOWER store, located on Nansong Yu Street in Hangzhou, features 36 honeycomb aluminum panels as suspended ceilings between beams. The lighting, fire protection, and HVAC equipment are hidden on top of the transparent ceiling, and the light is evenly reflected in the exhibition hall, seeking a balance between modernity and tradition.

C. Partition application

The emergence of honeycomb aluminum panel partitions has broken the traditional partition mode and has advantages such as fire resistance, corrosion resistance, easy assembly, easy removal, light weight, and convenient transportation.

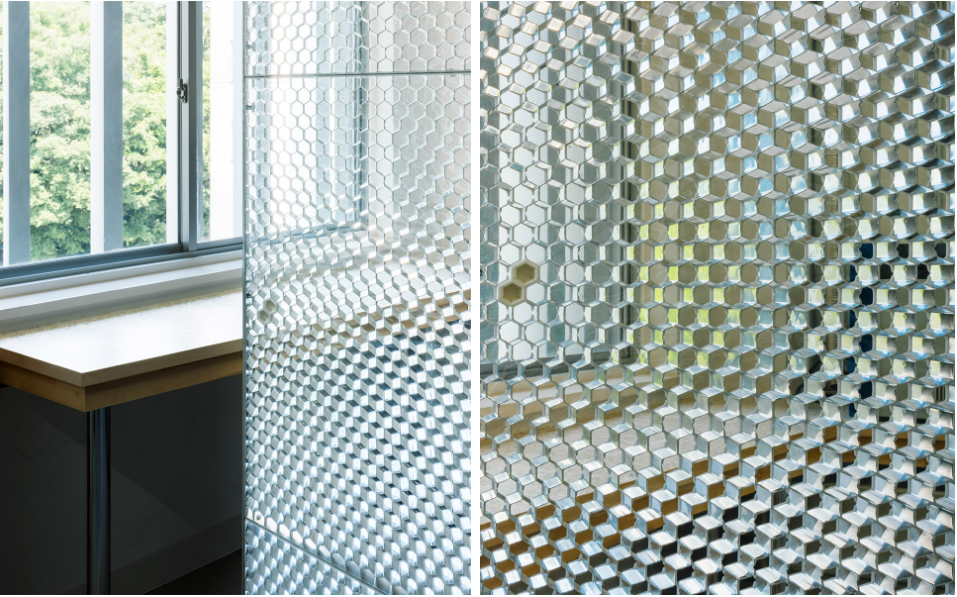

Kyushu University Paper Laboratory

Design: Masaaki lwamoto Laboratory, Kyushu University+ICADA

This project is to use the newly developed "origami type" aluminum honeycomb panel to create a Japanese style partition sliding door. The designer adopts a tilted honeycomb panel with a 45 degree angle between the honeycomb partition and the panel surface. The transparency of the panel changes with the observation angle, creating a unique multi image visual effect.

Article from Weixin Design