Coatings are essential building materials for buildings. Currently, there are a wide variety of coatings with complex names, and confusion often arises when selecting them. Additionally, the prices of various exterior wall coatings vary greatly. This article will analyze the technology and cost of commonly used paint products for building exterior walls.

01Overall Introduction to Exterior Wall Coatings

1 Industry Development Trends

External wall coatings are basically divided into ordinary non elastic latex coatings, elastic coatings (flat coating, roughening, embossing), textured coatings, real stone coatings, colorful coatings, water-based/oil-based fluorocarbon metal coatings (currently used less), and some special processes, such as the effect of plain concrete, such as finished products with sandstone like effect, limestone like effect, and ceramic colored stone.

In 2012, real stone paint rose to prominence and will compete with new coatings such as colorful coatings and texture simulation coatings to boost the paint market in 2013.

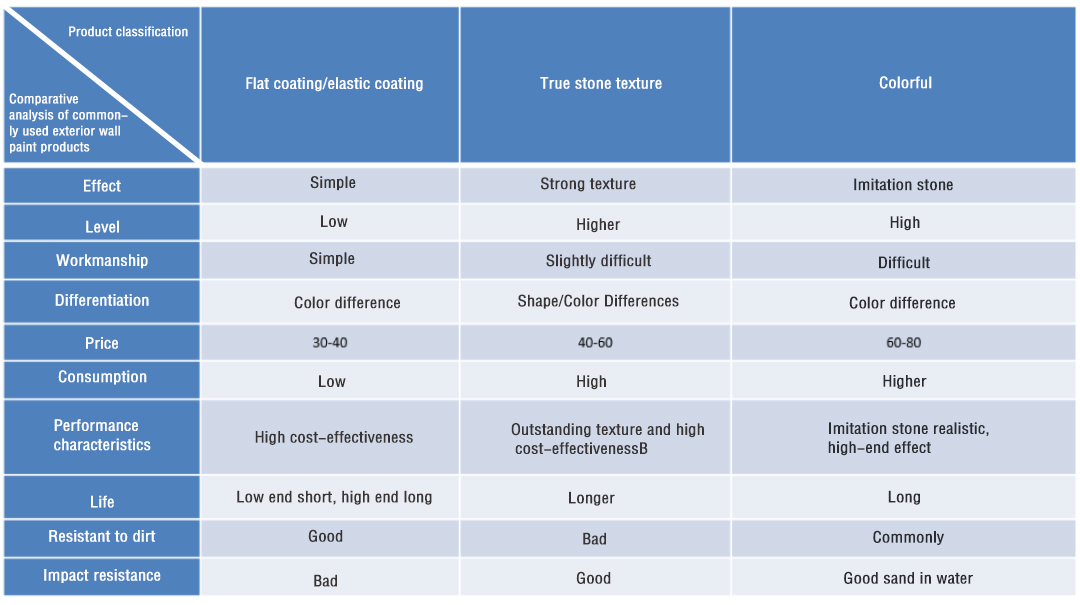

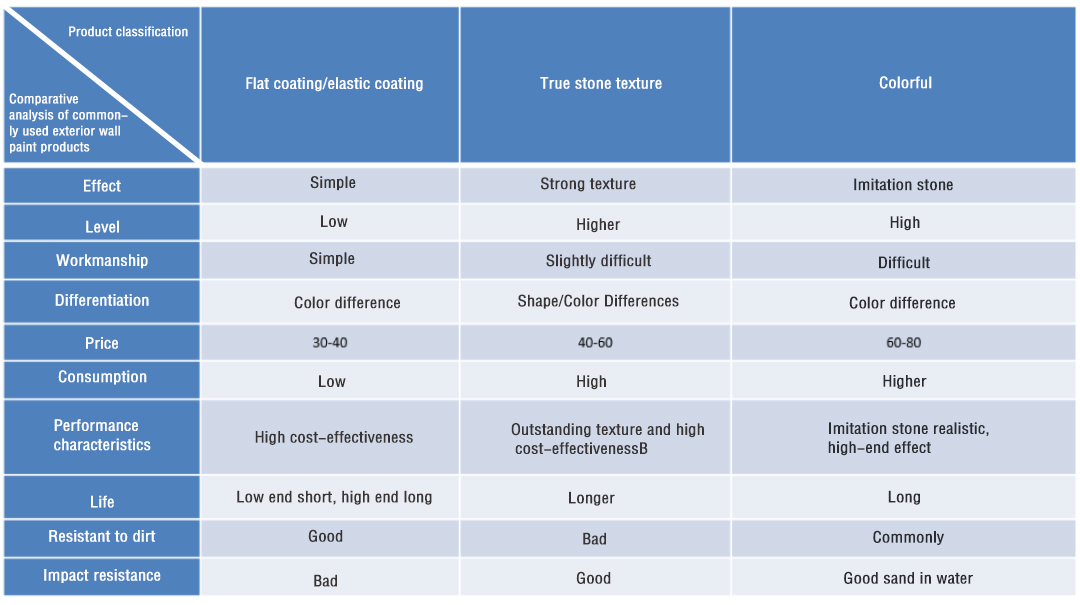

2 Comparison of commonly used exterior wall coatings

02Analysis of Various Exterior Wall Coatings

1Ordinary non elastic exterior wall latex paint.Only has cleaning and beautifying effects.

After a few years, a good latex paint can still remain as new without elasticity and has no effect on preventing small cracks. Not suitable for use in areas such as North China and Northwest China.

Can only be used in areas without external wall insulation such as East China and South China. More commonly used for building updates, walls, and inside balconies.

2Elastic coating

Elastic architectural coatings are made from synthetic resin as the base material, mixed with pigments, fillers, and additives. After applying a certain thickness, they have the function of covering small cracks caused by the expansion and contraction movement of the substrate.

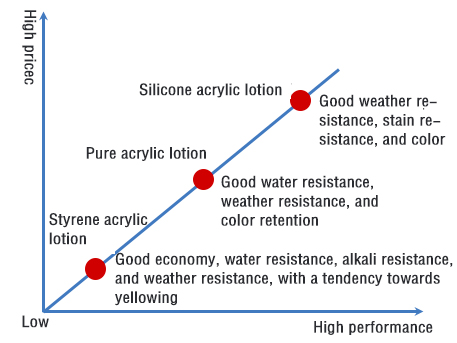

The main price difference in the general market is due to the different qualities of the resins used.

Suitable for areas with external wall insulation. As the external insulation is a combination of panels, it will cause misalignment with the settlement of the building, resulting in misalignment tension of the external wall coating and cracking of the coating. Therefore, it is necessary to make the external wall coating have elastic anti cracking function (resin).

According to the project design and construction process, it can be divided into flat coated, small patterned, large patterned, or embossed shapes, but its mechanism is inevitably more monotonous than textured coatings. It is generally used for high-rise main walls and other ancillary buildings in mid to low-end parks.

3Texture coating

Texture coating generally refers to the use of specific tools to paint and achieve a clearly personalized texture effect, which is different from ordinary flat coated interior and exterior wall coatings. The surface of the texture texture texture is formed by sand particles of different mesh sizes. Generally used in commercial outlets, local designs, high-rise main walls in mid to high-end parks, and mid range garden houses.

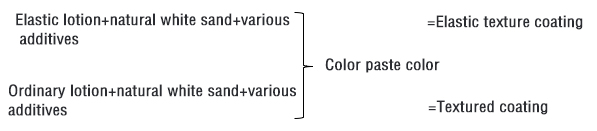

Texture coating composition

Characteristics of textured coatings

01The color of textured coatings is displayed through color paste, with variable shapes;

02Natural color texture, visual softness, diverse colors, and rich and colorful decorative effects;

03Excellent crack resistance;

04Convenient construction, easy operation, not limited by location, suitable for complex shapes;

05There are many construction methods, such as batch scraping and spraying.

Production process of textured coatings

The production process of textured coatings is divided into two steps:

01 Preparation of 01 textured slurry;

02Mix 02 texture paste with white sand and add color paste to make a texture coating.

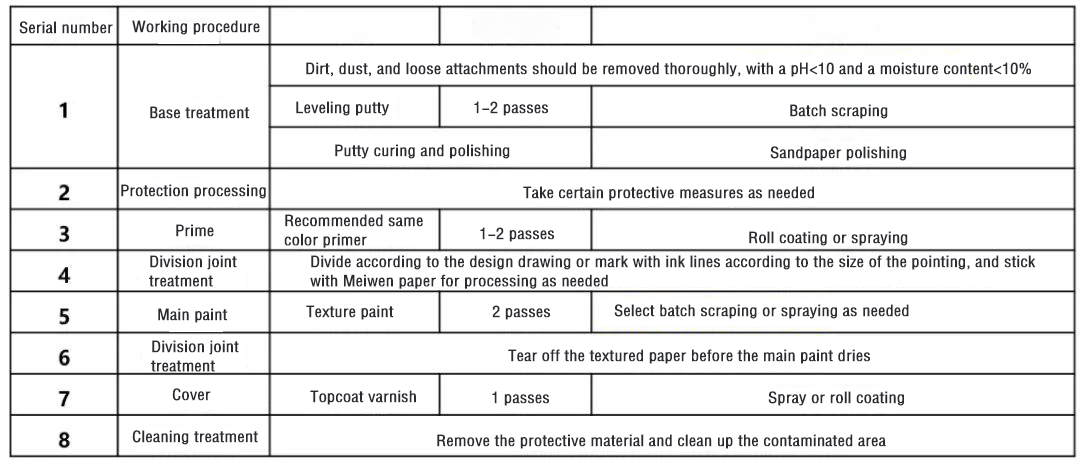

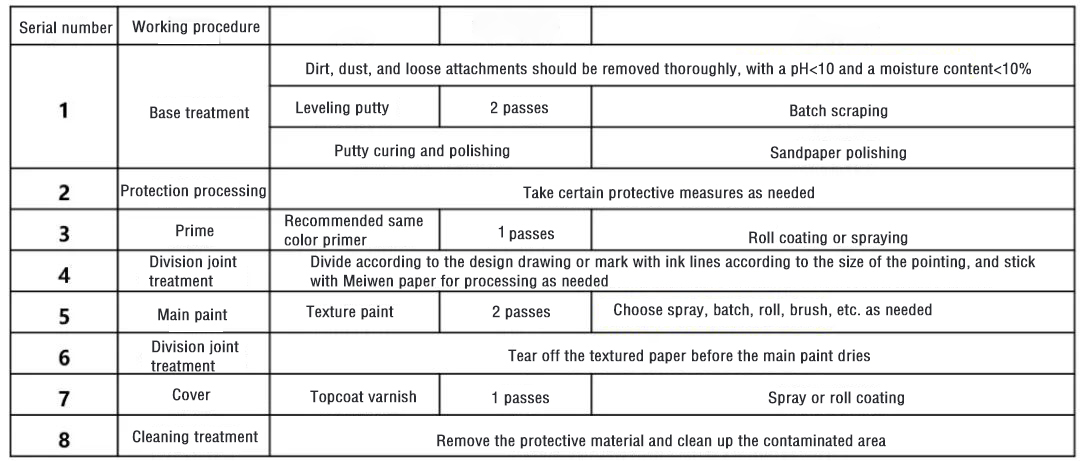

Construction technology

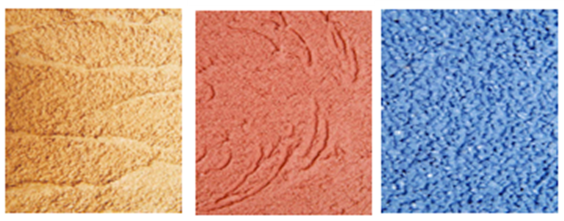

Common effects of textured coatings

4Genuine stone paint

Stone like paint, also known as natural stone like paint, stone like paint, and stone like paint, is a thick paste architectural paint composed of synthetic lotion as the base material, natural colored sand powder particles as the aggregate, and a small amount of additives. Its decorative effect is similar to marble, granite, White Marble, and marbles, especially for indoor columns, Roman columns, and other decorations, which can obtain a false and authentic decorative effect.

The color and shape of real stone paint are mainly achieved by adjusting the different colors and particle sizes of sand or rock slices in the formula. There are no special requirements for adding color paste for color adjustment. Real stone paint is mostly used in residential and commercial podium parts.

Real stone paint has advantages such as good decoration, wide applicability, simple construction, water-based environmental protection, and good weather resistance.

The main components of genuine stone paint

Lotion+sand mining+various additives=stone like paint

Lotion

Characteristics of natural sand mining

01 Various granite or marble natural ores are processed into granular and powdered products through multiple processes such as selection, crushing, crushing, grading, sand mixing, packaging, etc;

02 Excellent color retention performance, non fading;

04 Due to resource scarcity and insufficient supply, the number of varieties that can be stably supplied has decreased from 40 to 50 five years ago to around ten now.

Auxiliary

Commonly used additives include thickeners, antifreeze, preservatives, and film forming additives

Production process of real stone paint

The production process of real stone paint is divided into two steps:

01Preparation of real stone paint slurry

02The real stone paint is made by adding colored sand to the slurry for color mixing

Construction technology

Common effects of real stone paint

The difference between textured paint and real stone paint

01Different visual sensations

The imitation stone effect of real stone paint is realistic, and the degree of imitation stone can reach over 90%. Living in houses decorated with real stone paint can give people a sense of returning to nature, grand atmosphere, and solemn vitality. The most commonly mentioned thing about textured coatings is artistic effects. Designers use artistic aesthetics to outline abstract thinking on the wall, which can create a unique visual experience;

02Different construction processes

Most real stone paints are mainly sprayed, while texture coatings are mainly scraped in batches;

03Different materials

The aggregate of real stone paint is natural colored sand, and the main material of texture coating is texture sand. The color of natural colored sand has been determined from the moment of mining; The color of textured sand can be blended according to artificial synthesis. Texture coating is natural and environmentally friendly, non-toxic and odorless, both waterproof and breathable, making it a good decoration coating.

5Colorful Coatings

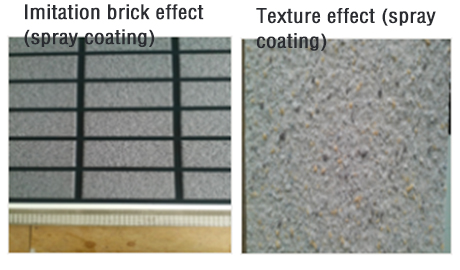

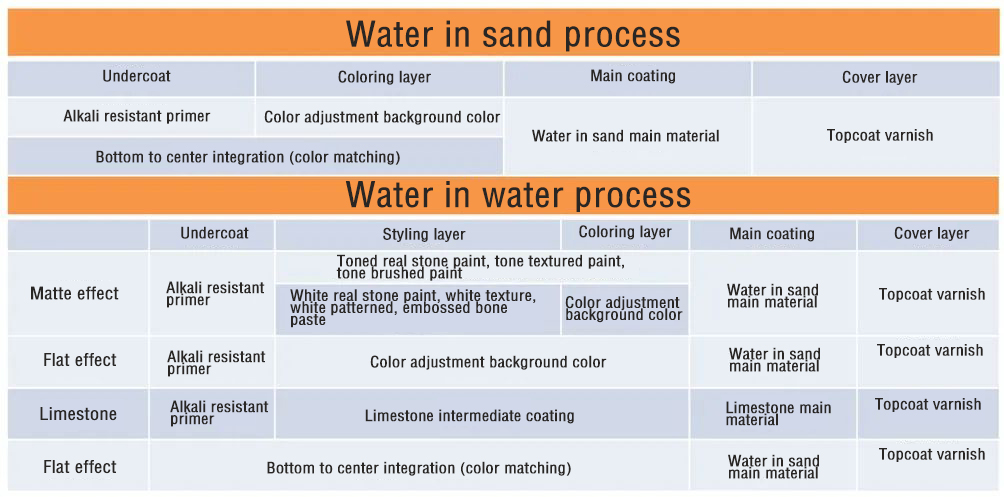

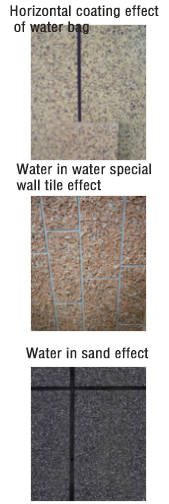

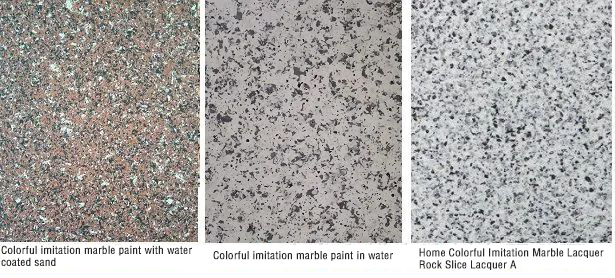

Colorful coating, also known as liquid granite paint, is a water-based coating used for building exterior walls, which is composed of two or more water-based colored particles suspended in a water-based intermediate layer and produced in multiple colors through a single spray. Water in water and sand in water are collectively referred to as colorful coatings.

Water in water coating is the first generation product of colorful coatings, mainly used for commercial facades along the street, high-end western-style houses, and high-rise first to third floor bases. Water in sand can be said to be an upgraded product that combines water in water and real stone paint, and is generally used in high-end residential areas.

Realistic stone decoration effect, ultra-high durability, green environmental protection, rich color, uniform effect, simple construction, and customization.

成型机理

How to identify water in water and sand in water?

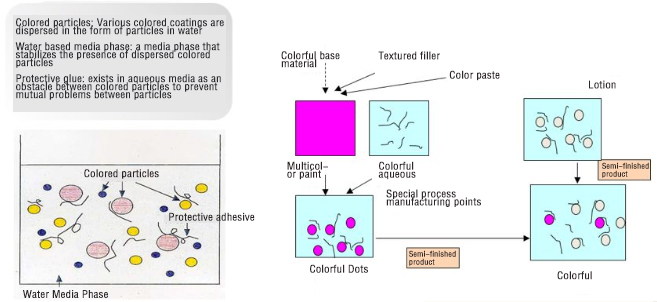

Composition of colorful coatings

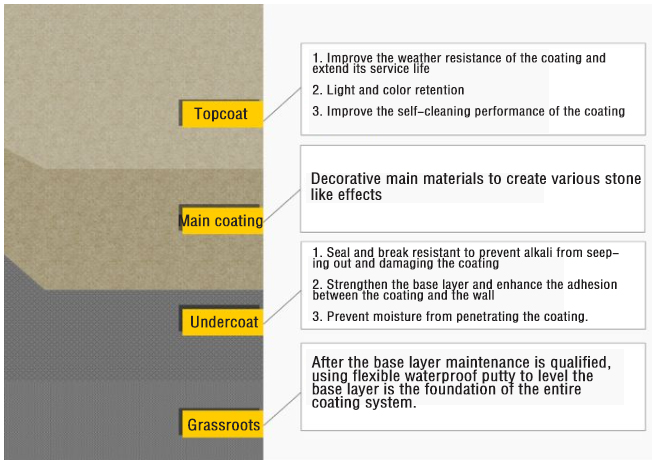

Colorful coatings are not a single product, but a combination and systematic product that includes primers, intermediate materials, and finishes.

Construction technology

Common Effects of Colorful Coatings

Characteristics of Colorful Coatings Products

01Simulation degree

The simulation level can reach 95%, almost identical to the original stone effect, with a sense of hierarchy;

02Pure inner and silicon inner synthetic lotion system, with ultra-high durability

Silicone acrylic and pure acrylic synthetic lotion system is adopted. The coating has strong adhesion, UV resistance and stain resistance. At the same time, ceramic inorganic pigments are used to ensure lasting color retention, which is suitable for exterior wall decoration of high-end and high-rise buildings. At the same time, the product is tested for mold resistance, stain resistance, elastic crack resistance, and resistance to high and low temperature differences in the environment;

03All water-based system, green and environmentally friendly

The coating materials of various systems of colorful coatings adopt EU environmental standards, are all water-based systems, and have extremely low VOC content. Construction (spraying) is absolutely non irritating. Easy and effortless spraying during construction;

04Rich colors, uniform and natural effects

Although imitating stone, it surpasses stone, with arbitrary color depth and pattern size, creating an artistic realm that granite cannot match. In addition, it completely avoids the serious color difference problem of natural granite;

05Simple construction method

The product is a single component water-based product, which can be sprayed with a single gun (dedicated spray gun) to obtain multi-colored textures, creating a colorful stone effect. The construction is simple and fast, the construction cycle is short, and damage repair is easy. Especially suitable for wall treatment with multiple heterosexual structures, it is easy to match various modeling lines, columns, reliefs, etc. for detailed color design processing. Special spray guns must be used, and brushing and rolling are not allowed. Even if it is a one-time construction, it requires multiple layers of spraying, unlike real stone paint;

06Customizability

Colorful coatings have professional customization, which can meet the needs and design corresponding color effects

Comparison between Colorful Coatings and Real Stone Paints

01 High fidelity: The appearance is closer to natural granite stone than real stone paint or rock flake paint, with a genuine imitation stone effect, and the fidelity can reach over 95%;

02 Staining resistance: Colorful coatings have high self-cleaning and waterproof properties, and dust will not penetrate and deposit on the paint film;

03 Water resistance: The coating has excellent waterproof performance compared to real stone paint;

04 Weather resistance: high content of lotion, weather resistance is 2 times of stone like paint;

05 Batch stability: Colorful coating products use pigments for color mixing. Batch stability and easy color mixing, while natural colored sand is used for color mixing in real stone paint and rock flake paint. Batch instability results in fewer and fewer natural colored sand;

06 Lightweight and safe: The physique is very light, about 0.5kg/m3, equivalent to 1/6 of dry hanging stone, especially suitable for external wall insulation walls.

03Performance and Cost Comparison

Source: Zhongliang Real Estate Procurement Platform

Article from New Micro Design