01What is a prefabricated building

Prefabricated buildings are buildings assembled from prefabricated components on construction sites, known as prefabricated buildings. According to the form and construction method of prefabricated components, it can be divided into five types: block building, sheet building, box building, skeleton sheet building, and rising floor building.

Development stage of prefabricated buildings in China:

Initial stage (1950-1977)

Slow development stage (1978-2010)

Rapid development stage (since 2011)

Background of relevant policies in China:

①At the end of 2015, the "Evaluation Standards for Industrialized Buildings" were released, and it was decided to comprehensively promote prefabricated buildings nationwide in 2016, achieving breakthrough progress;

②On November 14, 2015, the Ministry of Housing and Urban Rural Development issued the "Outline for the Modernization of the Construction Industry", which plans to have prefabricated buildings accounting for over 20% of new buildings by 2020 and over 50% of new buildings by 2025;

③On February 22, 2016, the State Council issued the "Guiding Opinions on Vigorously Developing Prefabricated Buildings", requiring the development of prefabricated concrete structures, steel structures, and modern wooden structures according to local conditions, striving to achieve a proportion of 30% of the newly built building area in about 10 years;

④On August 28, 2020, nine departments including the Ministry of Housing and Urban Rural Development, the Ministry of Education, the Ministry of Science and Technology, and the Ministry of Industry and Information Technology jointly issued the "Several Opinions on Accelerating the Industrialization Development of New Buildings". The suggestion is to vigorously develop steel structure buildings and promote prefabricated concrete buildings.

02How did prefabricated buildings emerge

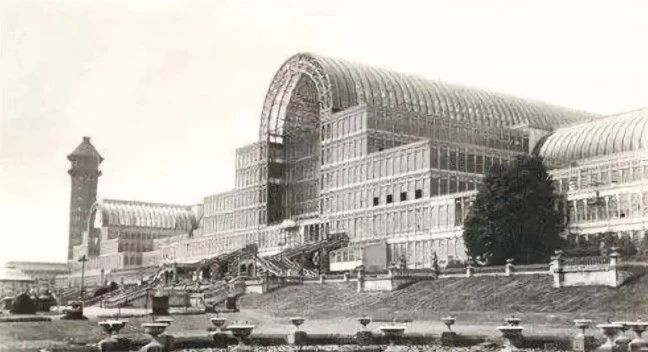

The Crystal Palace, built in London in 1851 with an iron skeleton and glass inlay, was the world's first large-scale prefabricated building. After World War II, there was a severe housing shortage in European countries and Japan, which urgently demanded solutions to the housing problem and promoted the development of prefabricated buildings. By the 1960s, prefabricated buildings were widely promoted.

With the development of modern industrial technology, building houses can be manufactured in batches and sets like machine production. Just transport the prefabricated building components to the construction site and assemble them.

Prefabricated architecture began to attract people's interest in the early 20th century and was finally realized in the 1960s. Britain, France, the Soviet Union and other countries were the first to make attempts. Due to the fast construction speed and low production costs of prefabricated buildings, they have quickly been promoted around the world.

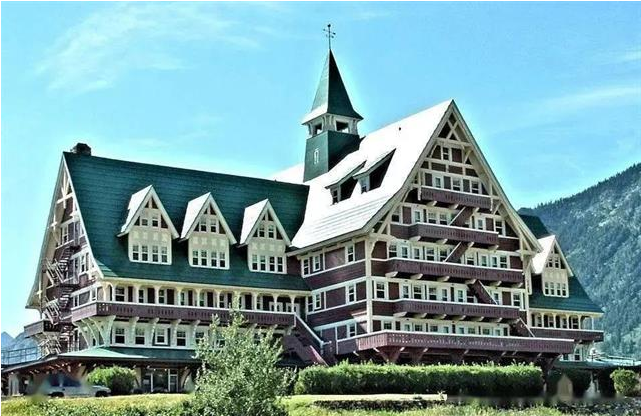

The early prefabricated buildings had a relatively rigid and uniform appearance. Later, people made improvements in design, increasing flexibility and diversity, allowing prefabricated buildings not only to be built in batches, but also to have rich styles.

03Classification of prefabricated buildings

From the classification of structural materials, prefabricated buildings can be generally divided into: prefabricated concrete system (PC), prefabricated steel structure system, and prefabricated wood structure system. At present, PC is still the main application in China.

①Prefabricated concrete

Common prefabricated concrete systems:

External hanging and internal pouring "PCF (prefabricated prefabricated external hanging wall panel) shear wall system with double-sided laminated plate shear wall system

Fully assembled integrated shear wall system

Prefabricated frame cast-in-place shear wall system

Fully assembled integrated framework system

Promotion system

②Prefabricated steel structure

Common fabricated steel structure system

Steel frame structure system

Steel frame supporting structure system

Steel frame ductile wallboard structural system

Staggered frame structure system

Portal frame structure system

Low rise cold-formed thin-walled steel structure system

Hierarchical assembly structure system

Steel tube bundle structure system

Other new structural systems

③Prefabricated wooden structure

04Development status of prefabricated buildings at home and abroad

① Domestic:

In recent years, the explosive development of prefabricated buildings in China stems from the demand for sustainable development and the promotion of national policies.

Prefabricated architecture has become one of the important construction industry policies in China at this stage.

In 2021, there will be about 1200-1500 enterprises producing prefabricated building components in China. A total of 328 National prefabricated construction industrial bases and 908 provincial industrial bases have been established throughout the country. Among them, 143 prefabricated component manufacturers, 190 flow production lines and 249 traditional lines have been registered in Shanghai, with an actual annual production capacity of about 6.14 million cubic meters. There are 27 prefabricated component manufacturers in Beijing and surrounding areas, with more than 45 production bases and a total design annual production capacity of more than 4.55 million cubic meters. There are about 20 manufacturers of fabricated components in Shenzhen, with an annual design capacity of 2.05 million cubic meters.

By the end of 2020, Shanghai, Beijing, Hunan, Zhejiang, Jiangsu, Tianjin and other regions have completed the target of 30% of the prefabricated building area in 2025 ahead of schedule.

② Abroad:

At present, the most representative countries for the development of prefabricated buildings abroad include the United States, Germany and Japan. These three countries are also countries with high market share of prefabricated construction abroad, of which the United States accounts for about 20%, Germany for about 18%, and Japan for about 7%, which originally accounts for 50% of the global prefabricated construction market.

05Advantages of prefabricated buildings

① Ensure project quality

Traditional on-site construction is limited by the uneven quality of workers, and quality accidents occur from time to time. While the prefabricated building components are produced in the prefabrication factory, the temperature, humidity and other conditions can be controlled in the production process, and the quality of components is easier to be guaranteed.

② Reduce potential safety hazards

Most of the special construction is in the open air and high-altitude operation, which has great potential safety hazards. After the components of the prefabricated building are transported to the site, the professional installation team strictly follows the process for assembly, which greatly improves the project quality and reduces the potential safety hazards.

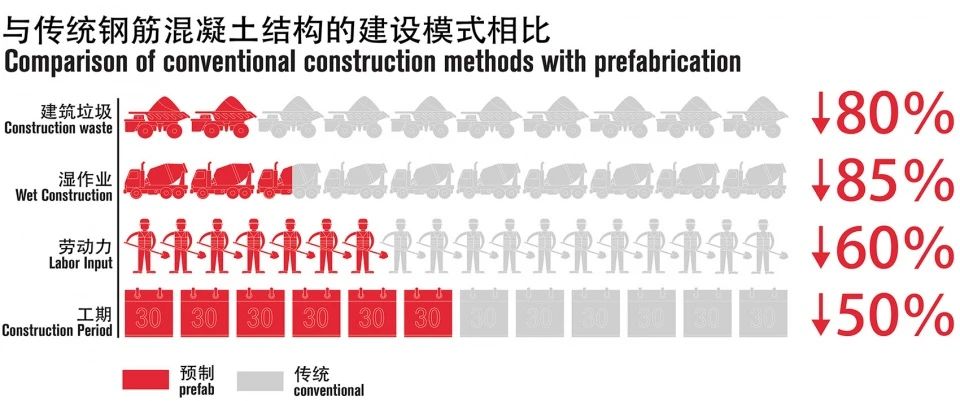

③ Improve production efficiency

The prefabricated building components are produced by the prefabricated factory in batches using steel formwork, reducing the number of scaffolds and templates, so the production cost is relatively low, especially when the production form of components is more complex, the advantage is more obvious: at the same time, the corresponding construction process is omitted, and the time utilization rate is greatly improved.

④ Reduce labor costs

At present, China's construction industry is short of labor, lack of technical personnel, older workers as a whole, and rising costs, which makes the traditional construction methods unsustainable. Because prefabricated buildings are constructed in prefabrication factories, on-site assembly construction has a high degree of mechanization, reducing the number of on-site construction and management personnel by nearly 10 times. Considerable labor costs are saved and labor productivity is improved.

⑤ Energy conservation, environmental protection and pollution reduction

The characteristics of circular economy of prefabricated buildings are remarkable. Because the steel formwork used can be recycled, a large number of scaffolds and formwork operations are saved, and wood resources are saved. In addition, because the components are produced in the factory, there is less wet operation on site, which greatly reduces the noise.

06Case of prefabricated building

A

R & D building of Huayang International Dongguan Industrial Park

Location: Dongguan / Design: Huayang International Design Group

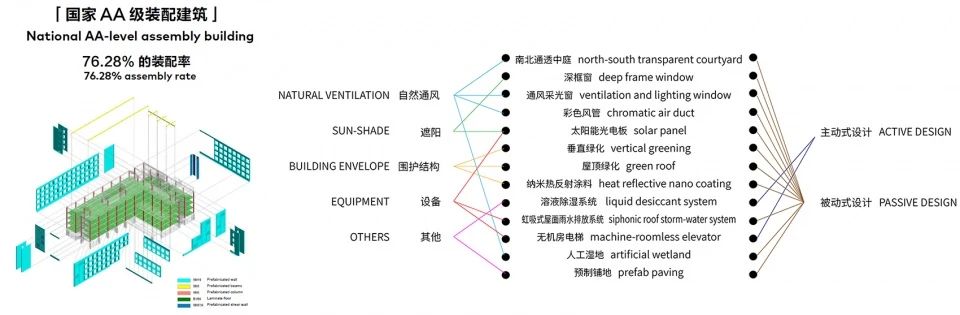

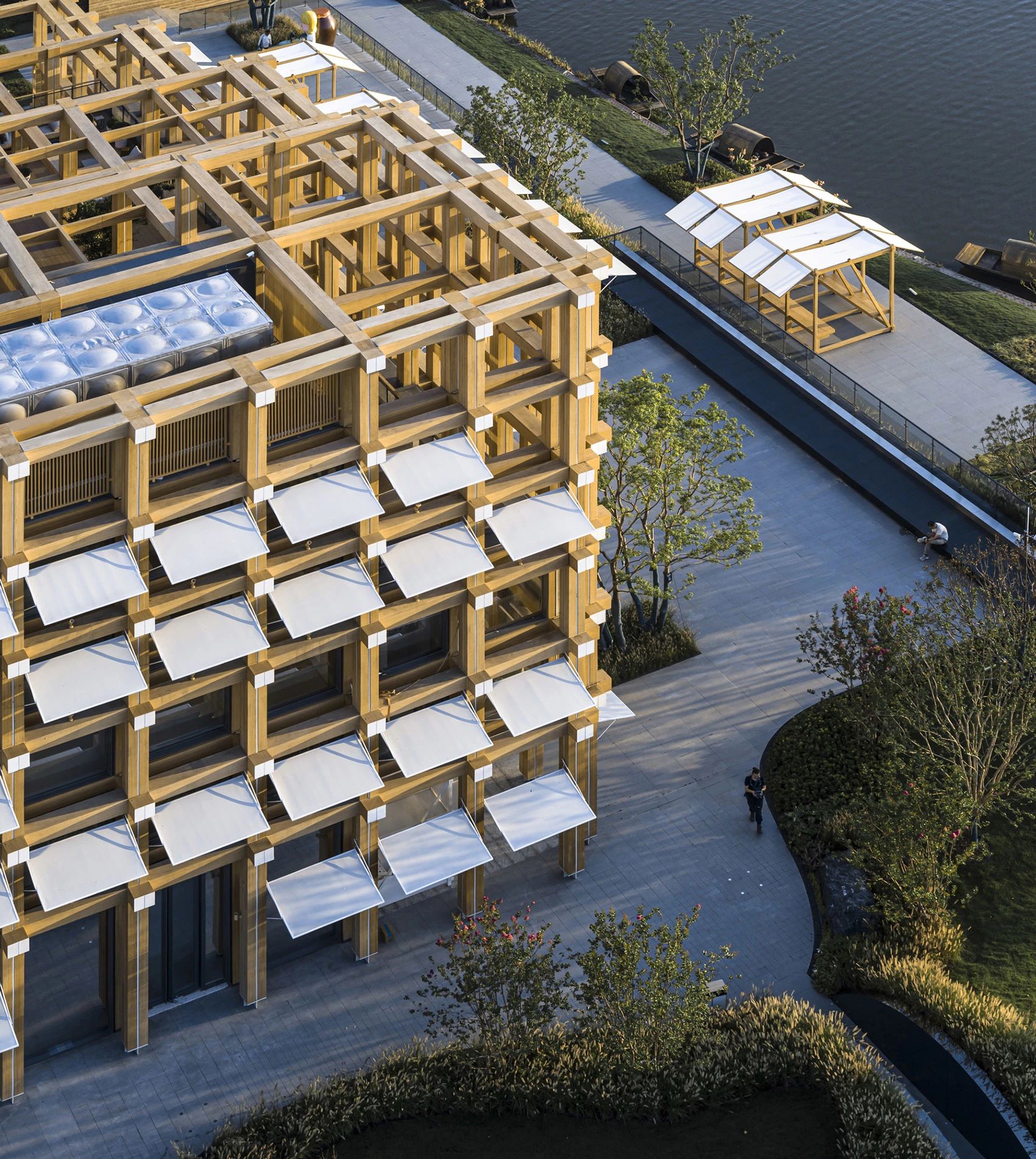

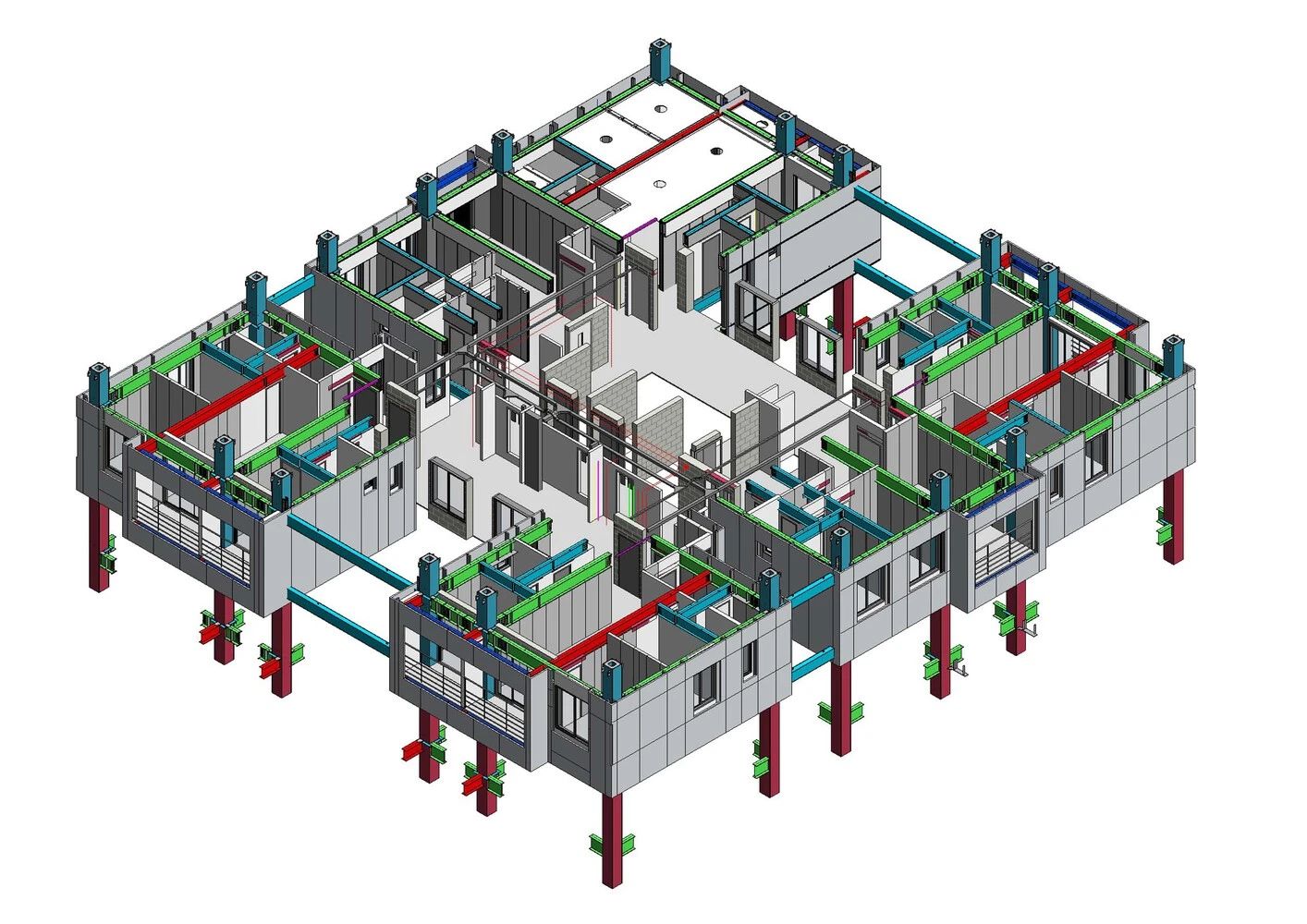

The overall assembly rate of dream office exceeds 76%, and it is a national AA prefabricated building. As a green building with a full life cycle, the project is built according to the international LEED full-scale standards. From the concept positioning, planning and layout, form materials, spatial structure, building material production, construction, use and operation and maintenance and other continuous quantities, it jumps out of the inherent mode of project design and operation, runs through the whole process of design with green building thinking, and looks for the contemporary innovation of low-carbon design.

B

Reception hall of Shaoxing Dongjiu town

Location: Shaoxing / Design: gad

The scheme adopts a more rapid and controllable steel frame structure. Drawing on the strong functional adaptability of the traditional wooden frame building and the domino building system, the scheme determines the 4.8mx4.8mx4.8m three-dimensional square as the basic module of the building.

C

Bosch auto parts parking building phase I

Location: Suzhou / Design: Zhongheng Design Group

The architect considered the precise deepening details in advance and provided the design details of all prefabricated components such as prefabricated flower slots, floor steel beams, column head joints, and floor profiled steel plates. According to the comprehensive evaluation standard for prefabricated buildings in Jiangsu Province, the standardization rate of components in the basic unit of the project reaches 100%; the application proportion of standardized prefabricated components reaches 95%.

D

Steel structure prefabricated public rental housing on the south side of Dongsheng Road, Zhanjiang City

Location: Zhanjiang / Design: yuanontology studio of Shenzhen University Architectural Design Institute

As one of the important pilot projects of the Ministry of housing and urban rural development and the Department of housing and urban rural development of Guangdong Province, this project does not adopt the traditional reinforced concrete structure, but adopts the form of steel structure + prefabricated components. The design of the suite follows the principle of finalization and serialization, and adopts the way of standardized layout of the large bay structure to meet the flexibility and variability of the space layout in the suite, as well as the requirements of standardization, modularization, serialization and table formation.

E

Shenzhen Pingshan Jinlong school

Location: Shenzhen / Design: Crossboundaries

In the whole school project, about 75% of the building area is built in assembly, which greatly reduces the construction waste on site and labor input, and the construction period is only 1/2 of that of conventional construction, saving budget and time. While adopting the fabricated structure, the architects of Crossboundaries emphasized the maximum flexibility and aesthetics, while providing ingenious solutions for high-density projects.

F

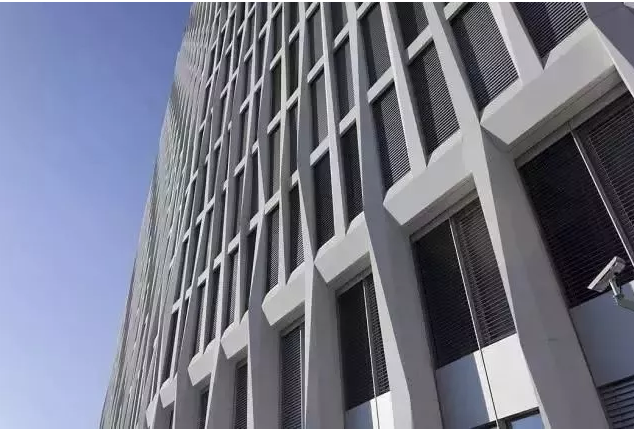

New project of Shanghai Thomas Experimental School

Location: Shanghai / Design: Architectural Design and Research Institute of Tongji University

Main facade materials: special color cement fiberboard for dry hanging facade, decorative aluminum plate, aluminum alloy corrugated plate, aluminum alloy perforated aluminum plate, etc. The project is a prefabricated building with a prefabricated assembly rate of 42%.

Article from new micro design