01.Material Summary

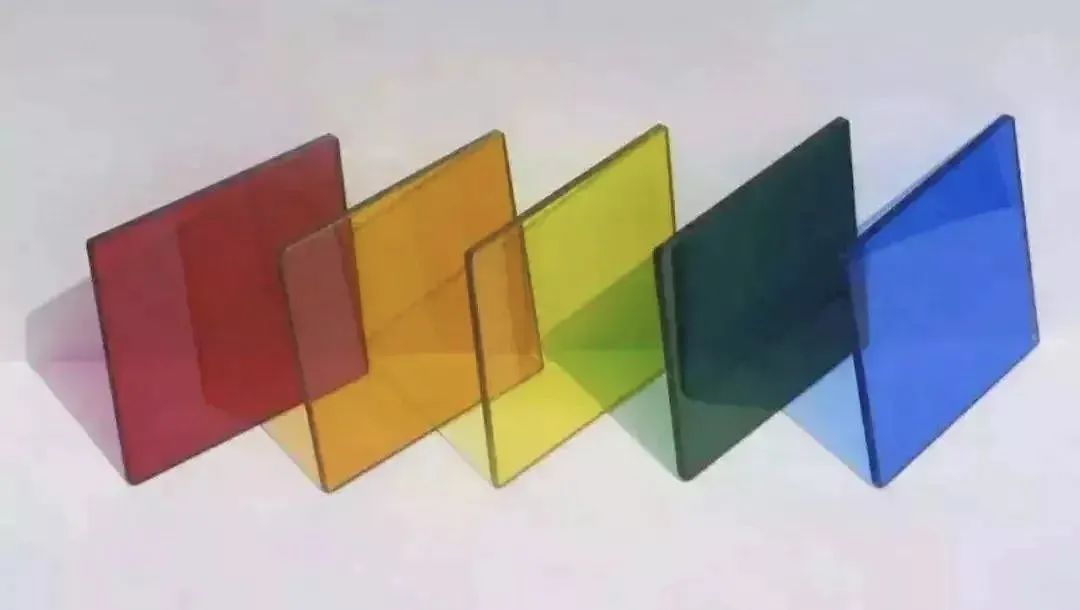

Electronic glass

a、Also known as dimmable glass, smart glass, or color changing glass, is a special type of glass that can change transparency as needed.

b、It uses current, photosensitive materials, or other technologies to adjust the transparency of glass, switching from a completely transparent to a semi transparent or completely opaque state.

▲Source: google.com

02.Material characteristics

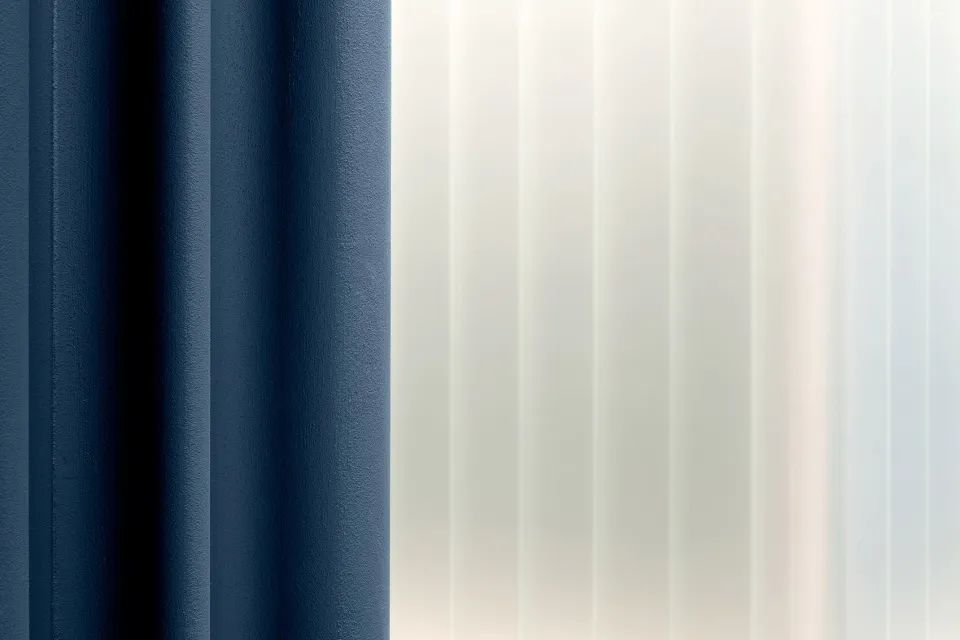

1) Adjustable transparency

Electronic glass can adjust its transparency through a control system to achieve a transition from transparent to opaque. This adjustable transparency enables it to provide privacy protection or light adjustment functions when needed.

2)High transparency

Electronic glass has high transparency in a transparent state, which can effectively transmit light, make indoor spaces bright, and increase the utilization of natural light.

3)Visual effect

Electronic glass can be used to display images, text, or other visual effects. When the electronic glass is in a transparent state, it can display clear images, while in an opaque state, it can hide the displayed content.

4)Energy efficiency

Electronic glass can achieve effective energy utilization by adjusting its transparency, controlling indoor sunlight and heat transfer.

5) Sound insulation performance

Electronic glass can provide a certain degree of sound insulation effect, reduce the transmission of indoor and outdoor sound, and create a quiet and comfortable environment.

6) Environmentally friendly

Electronic glass is manufactured using advanced materials and technologies, with lower energy consumption and environmental impact. At the same time, its adjustable transparency function also helps to save energy and reduce the demand for indoor lighting.

▲Source: google.com

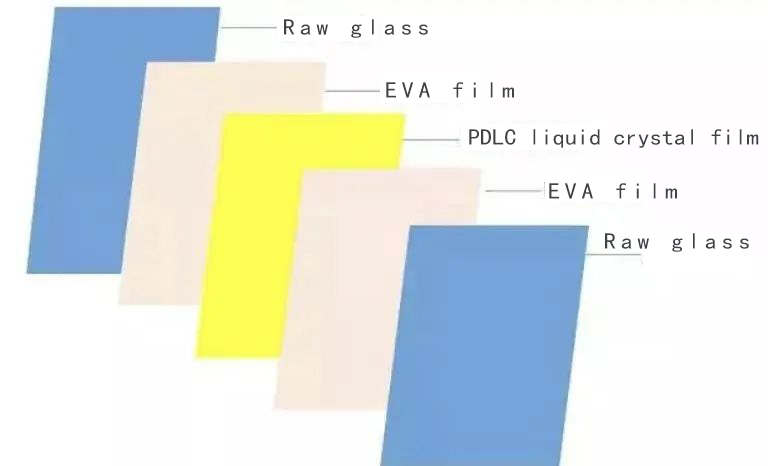

03. Material process

The production process of electronic glass:

1、Preparation of raw materials

Prepare the required glass substrate and electronic materials according to the requirements of electronic glass;

2、Coating preparation

Making electronic materials into specific coatings or thin films, usually coated on one side of the glass substrate;

3、Packaging processing

Encapsulate the glass substrate coated with electronic materials with other components to ensure the protection and stability of electronic components;

4、Control System Integration

Integrate electronic glass with corresponding control systems to achieve transparency adjustment;

5、Testing and quality inspection

Conduct testing and quality inspection on the produced electronic glass to ensure that its performance meets the requirements;

6、Cutting and processing

Cut and process electronic glass according to specific application requirements to meet the requirements of different sizes and shapes;

7、Packaging and Delivery: Packaging and preparing the finished electronic glass for sale and installation before leaving the factory;

▲Source: google.com

04.Application Cases

01.TH01 Light Source Space Project, Florence/DEFERRARI+MODESTI

A multifunctional dynamic environment with unlimited potential

▲Source: google.com

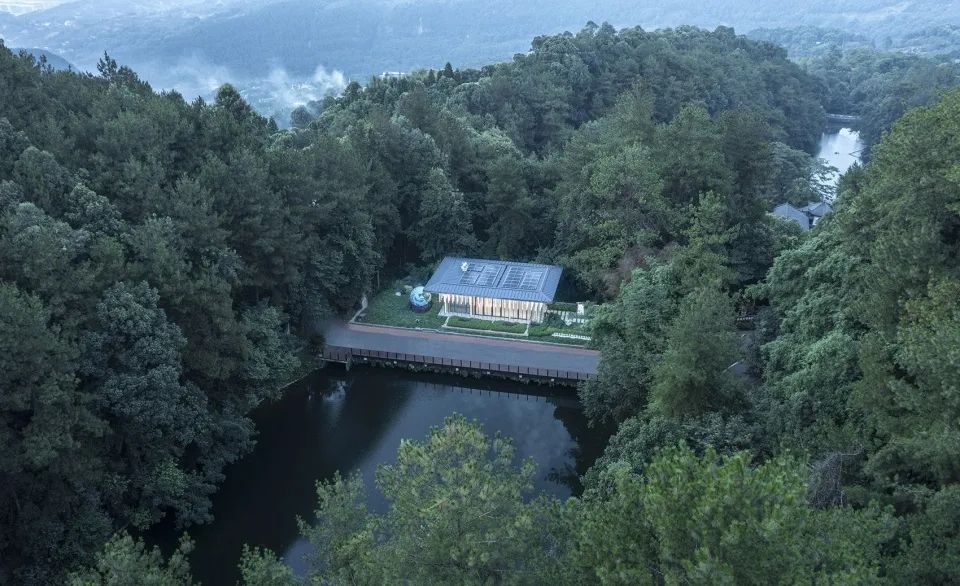

02.Beipai Xiuyun Zero Carbon Cabin, Chongqing/MCC Saidi

Realize the first real "Zero-energy building" in Chongqing

▲Source: google.com

Article transferred from design materials