01.Material Summary

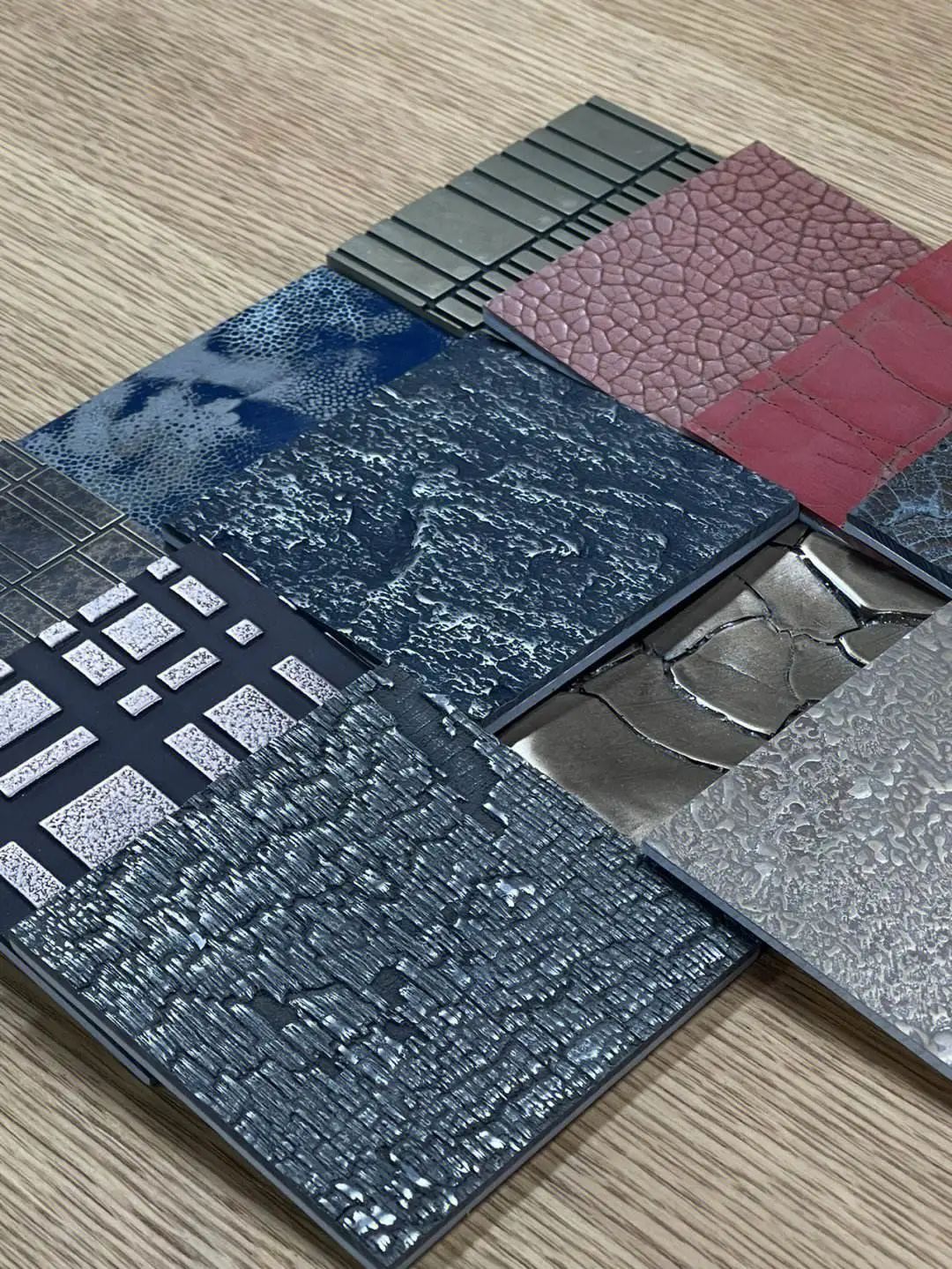

Liquid metal plate

Also known as metal coating, it is a special coating material that mainly consists of metal powder and liquid resin. Its characteristic is to form a metallic surface after coating, with a metallic appearance and texture, as well as the plasticity and protective function of the coating.

02.Material characteristics

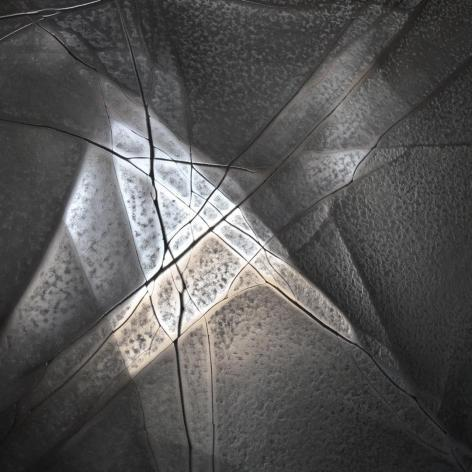

1)Metal texture

The surface of liquid metal plate has the texture of real metal, such as gold, silver, copper, etc., giving it a unique visual effect and artistic sense.

2)Decorative effect

Liquid metal sheets can provide a highly decorative effect for architecture and decoration, adding a luxurious, modern or unique appearance.

3)Possibility

Liquid metal plates have good plasticity and can adapt to various shapes and curved surfaces, achieving personalized design requirements.

4) Weather resistance

Liquid metal plates have good weather resistance and corrosion resistance, and can maintain stable appearance and performance in various harsh climatic environments.

5)Repairability

If there are scratches or damage on the surface of the liquid metal plate, it can be repaired through a repair process to restore its original appearance.

6)Environmental friendliness

The metal powder used in liquid metal plates is usually a renewable and recyclable material that meets environmental requirements.

03.Material process

Production process flow of liquid metal plate

1、Material preparation

Prepare metal powder, resin, and other additives as raw materials. The selection of metal powder can be determined based on the type of metal to be simulated, such as copper powder, aluminum powder, etc;

2、Mixing and blending

Mix metal powder, resin, and other additives in a certain formula ratio to obtain the required liquid metal material. The mixing process requires attention to the uniformity and stability of the material;

3、Table processing

Preparing the surface of the substrate to be coated usually requires processes such as cleaning, polishing, and pre-treatment to ensure the adhesion and surface quality of the coating;

4、Coating process

Use appropriate tools or equipment to apply the mixed liquid metal material onto the substrate. Painting can be carried out by spraying, brushing, or rolling, and multiple coats can be applied as needed to achieve the desired effect;

5、Drying and curing

After coating, place the substrate under appropriate environmental conditions for drying and curing. This process typically involves temperature and humidity control to ensure the stability and durability of the coating;

6、Post processing and finishing

After curing, necessary post-treatment processes such as polishing, polishing, and cleaning are carried out on the coating to improve surface quality and glossiness;

7、Pattern design and mold making

Create the desired pattern or texture on the liquid metal plate. This can be achieved through mold production, which adapts to different shapes and sizes according to design requirements;

8、Spraying and coating adjustment

Spraying and coating adjustment on liquid metal plates to increase color, texture, or other decorative effects can be achieved through different spraying techniques, masking, or adjusting the thickness of the coating;

9、Surface treatment and protection

Treat and protect the surface of liquid metal plates to increase their durability and corrosion resistance. This may include cleaning, polishing, applying protective agents, or using special coating processes;

10、Inspection and Quality Control

Inspect and control the quality of the produced liquid metal plates to ensure they meet the standards and requirements specified in the Taiwan regulations. This includes visual inspection, dimensional measurement, weather resistance testing, etc;

11、Packaging and transportation

After completing the quality inspection, the liquid metal plate should be appropriately packaged and labeled for transportation and safe storage.

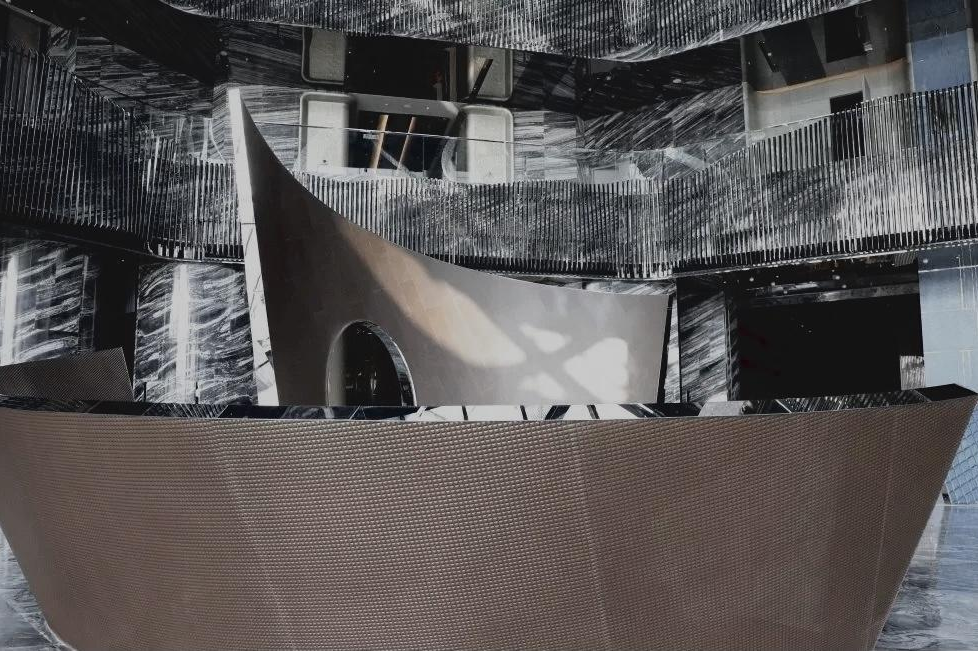

04.Case Application

01.Jewel Changi Airport Building Exploration Slide, Singapore/Carve+Playpoint

Adventure Tour at the Airport

Article transferred from design materials