When you see a large, complete, and smooth mirror stainless steel surface/sculpture, you may wonder how it was made? Today, let's share through a case study.

01.When using large area smooth and seamless mirror stainless steel in buildings

Simply put, first use a steel skeleton to build the structure, and then use software to cut stainless steel plates according to different curvatures and sizes. At present, most projects still rely on manual forging to verify and control accuracy using 3D scanning technology, which is then produced through transportation, lifting, welding, polishing, and other processes. Next, we will explain it in detail through two cases.

The "Future Eye" of Qushidai Future Building

The largest mirror seamless stainless steel dome in China

The most eye-catching spot at the Qushidai Future Building project site is the largest mirror seamless stainless steel curved roof in China, located in the "Future Eye" of Building 3 in the center of the building, with an area of nearly 3000 square meters.

I saw that the entire curved ceiling mirror was smooth, with a perfect loneliness like a shining eye embedded in the middle of the Future Building, reflecting the blue sky, white clouds, and surrounding buildings with a sense of technology, future, and art.

The "Eye of the Future" is the most difficult construction difficulty in the future building complex. The stainless steel curved roof of a building with a total area of 3000 square meters does not have the same curvature as a single plate. It all relies on manual forging, goes through thirteen processes such as lifting, welding, polishing, and so on. It takes about a year to overcome the heavy technical difficulties before it can be perfectly presented.

▼Construction process

Chengdu Science Museum

Atrium flying ladder is wrapped in mirror stainless steel

In October this year, the 81st World Science Fiction Congress will be held in Chengdu. It is Shanghai Construction Engineering Decoration Group that provides home venue services for this first world-class science fiction event held in China. The Chengdu Science Museum is built with a full industry chain EPC project general contracting model.

The project was designed by Zaha Hadid Architects. The total construction area of three floors above ground and one floor underground is 59600 square meters, with a refined decoration area of approximately 32000 square meters. Currently, the project construction has entered the sprint stage and is expected to be completed in August this year.

▲Atrium Flying Ladder and Sci Fi Eye Renderings

Entering the "Science Fiction Eye" atrium, there is a flying ladder that diagonally penetrates the space. The engineers of the Decoration Group have optimized and decomposed the original non-standard escalator scheme that carried decorative loads into a mirror stainless steel outer skin self bearing system and a standard escalator component. The two independent systems have shortened the processing cycle of the original non-standard component from 4 months to 2 months for the standard component. Effectively reduce resonance safety hazards while ensuring completion of the nodes.

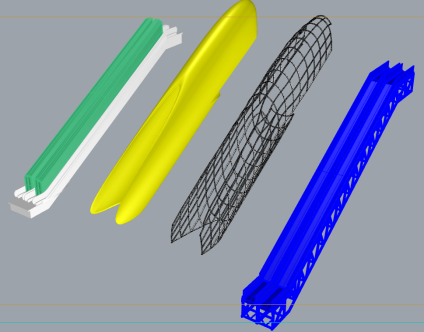

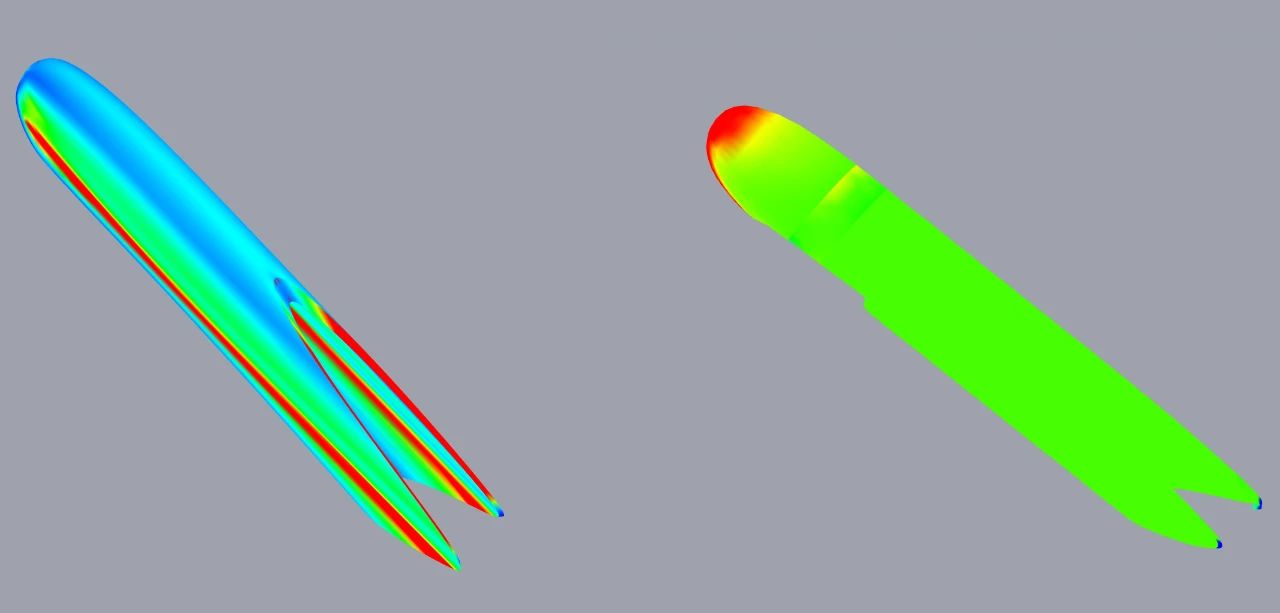

▲The original escalator frame bears the stress system of stainless steel veneer

The processing and installation of the stainless steel decorative outer surface of the Feitian ladder with irregular curved surfaces are very difficult. To this end, the decoration group has developed a single curvature optimization design technology for double-layer mirror seamless stainless steel decorative skin based on Rhino and Grasshopper, guided by parametric design. Not only does it reduce the difficulty of processing stainless steel decorative plates, but it also eliminates the warping gaps between plates, which can effectively improve the installation quality of plates. The stainless steel decorative surface adopts high-precision processing and modular installation techniques such as block processing, on-site assembly, laser welding, and multi wheel polishing, transforming construction difficulties into engineering highlights and truly achieving seamless mirror effect.

After finishing the large mirror stainless steel work, let's take a look at the small sculpture.

02.Stainless steel sculpture

When it comes to stainless steel sculpture, the first thing to be mentioned is Kapoor's design of "Cloud Gate" in Millennium Park, Chicago. The production method of stainless steel sculpture is illustrated by sculptures of this size.

The method used is forging and forming. Before production, the stainless steel sculpture will be decomposed into multiple units based on the shape and characteristics of the sculpture, in order to facilitate molding. The unit product will be formed in this way. Combine them into a whole on the steel skeleton, and finally weld and polish the whole for treatment. In fact, it is similar to the application method on buildings mentioned above.

But for smaller stainless steel sculptures that are often seen in sales office demonstration areas or shopping centers, there is a slight difference in the production process. Stainless steel sculptures are also generally made by hand, but generally foam mold is used to carve 1:1 model with foam.

Divide the outer surface of the entire sculpture into many small pieces, each with a row number. The raw materials used for stainless steel cold processing are pre made, and workers with different thicknesses of stainless steel plates need to draw corresponding shapes on the stainless steel plates according to the numbered small areas. Utilize the ductility of metal to create a three-dimensional appearance that matches the appearance of the sculpture. After each piece is made, it needs to be temporarily fixed on the foam mold.

After the appearance of all small parts is formed, they are welded together for polishing treatment.

Cloud Gate in Millennium Park, Chicago, USA

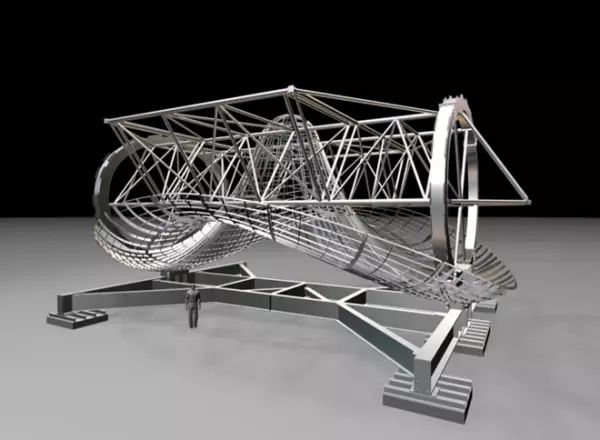

Located in Millennium Park, Chicago, USA, this work has become a representative landmark of Chicago since its completion in 2006. This sculpture, which is 20 meters long, 13 meters wide, and 10 meters high, is made of 168 stainless steel plates and weighs 100 tons. The creation of this work is inspired by mercury, and the smooth surface of the sculpture reflects and distorts the urban skyline of Icago. Audiences walking under the sculpture will have a special experience of creating multiple mirrors. I will show you a few process diagrams of the steps to create 'Cloud Gate'.

1. Build an internal support rack.

2.Install pre made steel plates one by one.

3.Use 3D scanning technology to inspect the final dimensions, and manually polish any unsuitable areas to the nearest thousandth of an inch.

Each steel plate needs to be fixed separately, without relying on any surrounding steel plates, which minimizes the possibility of deformation.

4.The steel plate is first fixed by spot welding between the steel plates, and then a full penetration weld is used.

5.Grind the weld seam, sequentially and gradually, from coarse to fine, until it reaches the jewelry level.

6.Final completion.

Case study of stainless steel sculpture sketches

▼Tianyue Mansion, Peacock City, New Xitang, Jiashan

▼Tianjin, Colorful Love

▼Tianyun Dike in the Liangyi of Shangrao, Jiangxi Province

▼Xuzhou Dexin · Future Wing

▼Yunnan Zhongjian Jinke Xiangshan Island

03. Design Planning Considerations

The stainless steel sculpture technology is already very mature, but when applying large area smooth and seamless mirror stainless steel on the building surface, the following aspects need to be noted:

一、Selection of light environment:

Large area mirror stainless steel can have a significant impact on the surrounding environment due to its reflected light during use. Therefore, when selecting a site, consideration should be given to the light source and direction of the surrounding environment to avoid excessive reflection, which may cause eye fatigue or community interference.

二、Feasibility of construction technology:

Fine process processing is required, including cutting, welding, polishing, and other processes. Therefore, when selecting the construction team and construction plan, it is necessary to consider the construction conditions and personnel technical level to ensure the feasibility of the process.

三、Material selection:

The quality of steel has a significant impact on the service life and overall effectiveness of buildings. Therefore, it is necessary to choose high-quality stainless steel materials to ensure their surface smoothness and glossiness. When selecting materials, it is also necessary to consider fire resistance, anti-corrosion performance, and antioxidant performance to ensure the safety and long-term use of their buildings.

四、 The effect and aesthetics of the building:

Large area mirror stainless steel is crucial for its architectural effect and aesthetics as a building material. When designing, it is necessary to consider the overall shape and style of the building, avoiding excessive collages and tedious details to ensure its overall sense and blank effect. At the same time, it is also necessary to consider its reflection effect and color changes at different times and weather conditions to ensure the stability and aesthetics of the overall effect.

Article transferred from design materials