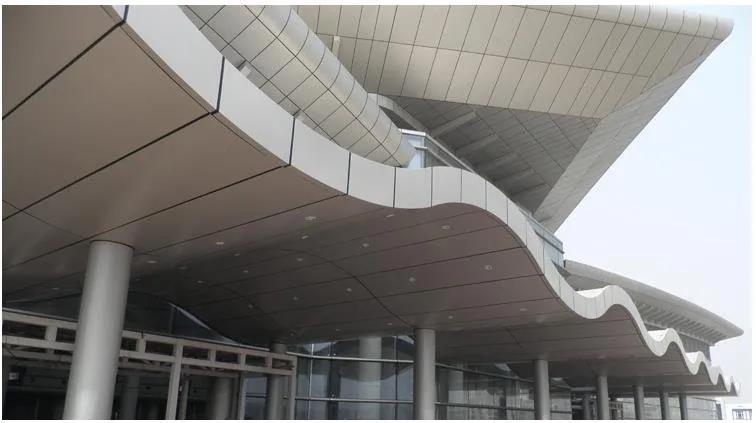

Aluminum curtain wall has unique texture, rich and lasting color, and the appearance shape can be diversified, and can be perfectly combined with glass curtain wall materials and stone curtain wall materials. With its perfect appearance and excellent quality, it is favored by the owners. Its self weight is only one-fifth of that of marble and one-third of that of glass curtain wall, which greatly reduces the load of building structure and foundation, and has low maintenance cost and high performance price ratio.

In recent years, there have been more and more all aluminum curtain wall buildings. Although the style is beautiful and the effect is good, the flatness (wave surface) of its facade is also emerging one after another.

In a concise sentence, the project manager of a project explained the root cause of such problems, that is, the uneven aluminum plate, with materials accounting for 40% and construction accounting for 60%. In fact, each link is indispensable.

Main cause:

1. Deepening design

2. Aluminum plate material

3. Aluminum plate processing and transportation

4. Keel system

Detailed design:

1. Folding scale: the folding scale of aluminum plate factory is usually 20mm, but in the project, due to some modeling requirements, the designer usually directly widens the folding scale. Such an approach will increase the accumulation of plate surface deformation, and also increase the probability of aluminum plate deformation during transportation and storage.

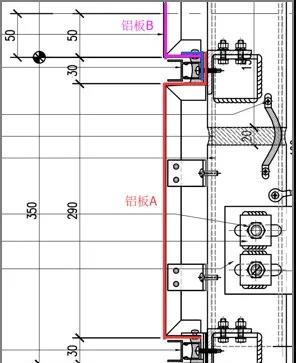

As shown in the figure above: the upper double folding edge of aluminum plate a (indicated by the red line) is fixedly connected with the angle steel beam screw, which belongs to line contact, and the installation accuracy is required to be higher than that of point contact (angle aluminum lug); If the flatness of skeleton surface and aluminum plate connection surface is not enough, error accumulation is easy to occur;

The lower folding edge of aluminum plate B + angle aluminum lug are superimposed above the folding edge of aluminum plate A. this connection mode requires a difference of aluminum plate thickness (2.5mm) between the upper and lower entrance and exit, while the upper and lower entrance and exit of other aluminum plates are flat (all connected by lugs), which is easy to increase the probability of wrong cutting and aluminum plate processing by constructors, thus affecting the flatness of aluminum plate.

2. Specification and thickness of aluminum plate. Nowadays, in order to pursue better results, it is common for plates to become larger, but the expanding specifications also pose a greater challenge to the flatness of aluminum plates.

3. Surface treatment process and color system of aluminum plate. The flatness of light color materials is generally better than that of dark color materials.

Aluminum plate material:

Base material: aluminum veneer aluminum veneer curtain wall adopts high-quality and high-strength aluminum alloy plate, with common thickness of 1.5, 2.0, 2.5 and 3.0mm, model of 3003 and state of H24.

Thickness: 2.5mm (no negative tolerance), thickened to 3mm and 4mm to help improve flatness.

Aluminum plate processing and transportation:

1. Aluminum plate manufacturers are required to have certain equipment input and production and processing capacity.

2. For the processing of aluminum plate, it is recommended that the stiffener of aluminum plate should be separated from the folded edge of aluminum plate (not connected), and a gap should be reserved:

3. The transportation process is also a link worthy of attention. The disorderly stacking of plates will aggravate the self deformation of metal aluminum plates in the transportation process.

Keel system:

At present, the common phenomenon in the market is the contradiction between effect and cost. Strict cost control is the most important element indispensable to every project. At present, steel keel has become the main support system, but the actual effect is not ideal. Therefore, it is suggested to give priority to aluminum alloy keel system when conditions permit.

Economic Analysis:

Serial number | Basic items | Project promotion | YUAN/㎡ |

1 | 2.5mm thick aluminum veneer | 3.0mm thick aluminum veneer | 25.0↑ |

2 | Steel keel supporting structure | Aluminum keel supporting structure | 40.0↑ |

3 | Installation of ordinary aluminum corner code | Lug mounting | 100.0↑ |

4 | Conventional stiffener arrangement @ 600 | Densified stiffener @ 400 | 25.0↑ |

5 | Ordinary smooth finish process of aluminum veneer | Embossing technology of "litchi surface" of aluminum veneer | 30.0↑ |

Overview:

At present, the performance of aluminum curtain wall has attracted high attention in the industry, whether it is uneven or easy to pollute the facade. We should treat the development of aluminum curtain wall with the concept of development, pay attention to research technology, improve curtain wall technology, and strive to integrate with international advanced technology to make aluminum curtain wall have better decorative effect.